1

/

of

5

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 223.54-1987 English PDF (GB/T223.54-1987)

GB/T 223.54-1987 English PDF (GB/T223.54-1987)

Regular price

$75.00

Regular price

Sale price

$75.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 223.54-1987: Methods for chemical analysis of iron, steel and alloy - The flame atomic absorption spectrophotometric method for the determination of nickel content

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 223.54-1987 (Self-service in 1-minute)

Newer / historical versions: GB/T 223.54-1987

Preview True-PDF

Scope

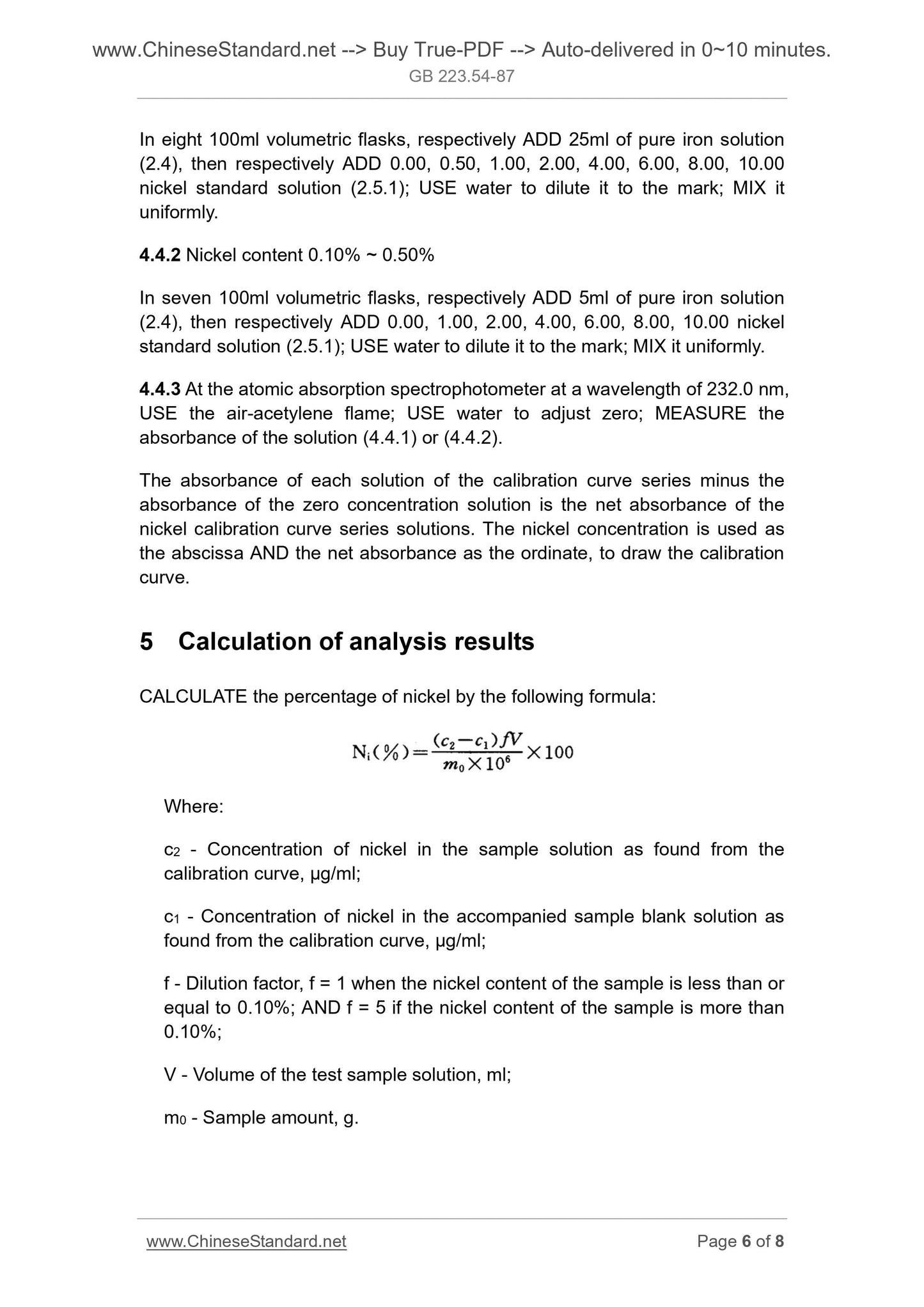

The sample is decomposed with appropriate mixed acid, perchloric acid isadded to evaporate it to produce smoke, AND water is used to dissolve the salt.

The sample solution is sprayed into the air-acetylene flame, and the copper

hollow cathode lamp is used as the light source. The atomic absorption

spectrophotometer is used to measure the absorbance at the wavelength of

232.0nm.

To eliminate matrix effects, when drawing the calibration curve, it shall add the

iron the amount of which is similar to that of the sample solution.

Basic Data

| Standard ID | GB/T 223.54-1987 (GB/T223.54-1987) |

| Description (Translated English) | Methods for chemical analysis of iron, steel and alloy - The flame atomic absorption spectrophotometric method for the determination of nickel content |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | H11 |

| Classification of International Standard | 77.08 |

| Word Count Estimation | 3,328 |

| Date of Issue | 5/12/1987 |

| Date of Implementation | 3/1/1988 |

| Issuing agency(ies) | Ministry of Metallurgical Industry |

| Summary | This standard applies to iron, carbon steel, low alloy nickel content. Measurement range: 0. 005 to 0. 50%. |

Share