1

/

of

10

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 22224-2008 English PDF (GB/T22224-2008)

GB/T 22224-2008 English PDF (GB/T22224-2008)

Regular price

$160.00

Regular price

Sale price

$160.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 22224-2008: Determination of dietary fiber in foods -- Enzymatic gravimetric method and enzymatic gravimetric method -- Liquid chromatography

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 22224-2008 (Self-service in 1-minute)

Newer / historical versions: GB/T 22224-2008

Preview True-PDF

Scope

1.1 ScopeMethod One of this Standard specifies the conditions and detailed analysis

steps for the determination of total, soluble and insoluble dietary fiber in foods

by enzymatic-gravimetric method.

Method One of this Standard is applicable to the determination of total, soluble

and insoluble dietary fiber in cereals, vegetables and fruits as well as their

products. But it is not applicable to the determination of dietary fiber in foods

containing low-molecular-mass resistant maltodextrin, oligofructose, galacto-

oligosaccharides, polyglucose and resistant starch.

1.2 Normative references

The provisions in following documents become the provisions of this Standard

through reference in this Standard. For dated references, the subsequent

amendments (excluding corrigendum) or revisions do not apply to this Standard,

however, parties who reach an agreement based on this Standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

GB/T 5009.3-2003, Determination of moisture in foods

GB/T 5009.4-2003, Determination of ash in foods

GB/T 5009.5-2003, Determination of protein in foods

1.3 Terms and definitions

For the purposes of Method One of this Standard, the following terms and

definitions apply.

1.3.1 dietary fiber

μmol of p-nitrophenyl per minute).

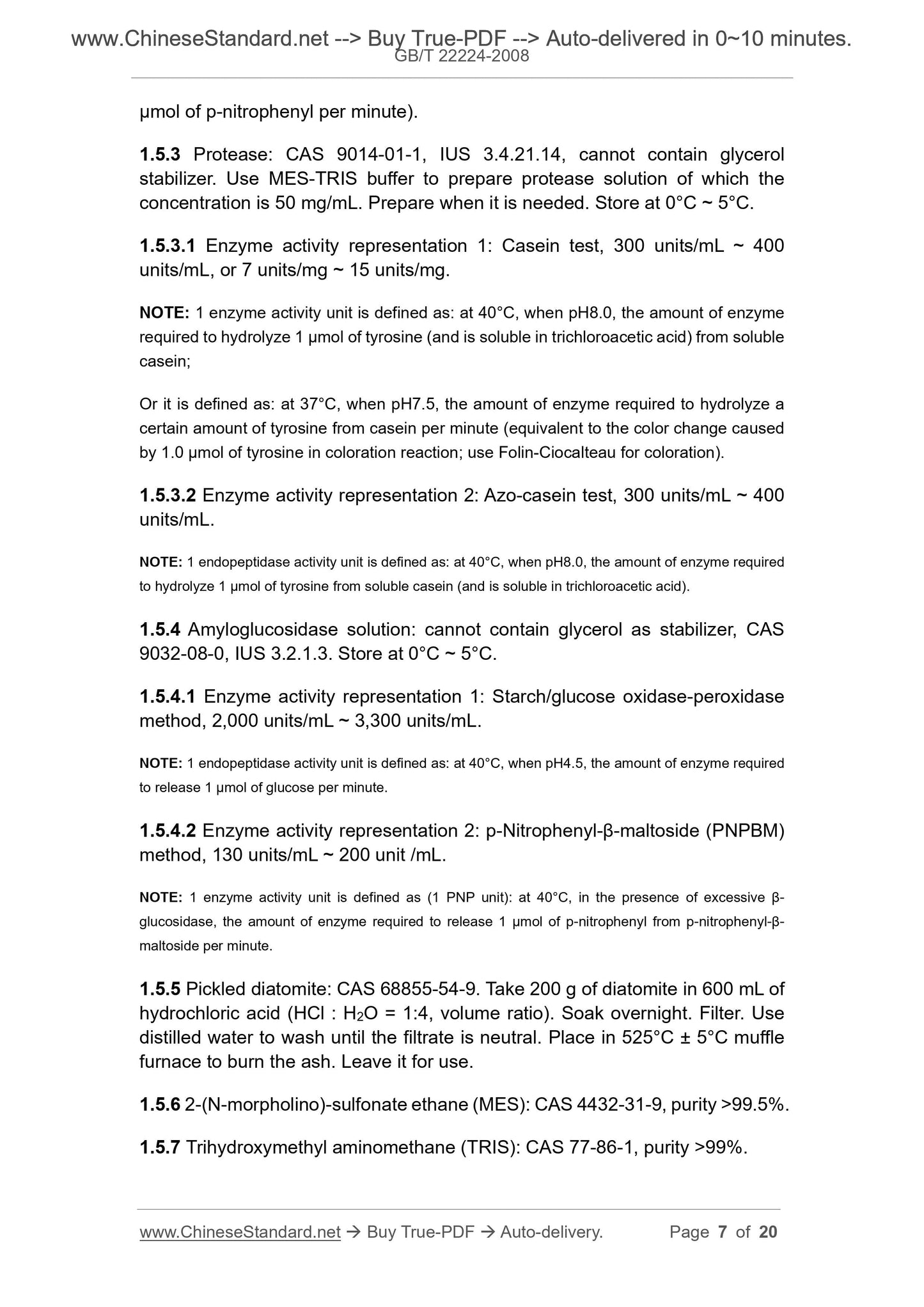

1.5.3 Protease: CAS 9014-01-1, IUS 3.4.21.14, cannot contain glycerol

stabilizer. Use MES-TRIS buffer to prepare protease solution of which the

concentration is 50 mg/mL. Prepare when it is needed. Store at 0°C ~ 5°C.

1.5.3.1 Enzyme activity representation 1: Casein test, 300 units/mL ~ 400

units/mL, or 7 units/mg ~ 15 units/mg.

NOTE: 1 enzyme activity unit is defined as: at 40°C, when pH8.0, the amount of enzyme

required to hydrolyze 1 μmol of tyrosine (and is soluble in trichloroacetic acid) from soluble

casein;

Or it is defined as: at 37°C, when pH7.5, the amount of enzyme required to hydrolyze a

certain amount of tyrosine from casein per minute (equivalent to the color change caused

by 1.0 μmol of tyrosine in coloration reaction; use Folin-Ciocalteau for coloration).

1.5.3.2 Enzyme activity representation 2: Azo-casein test, 300 units/mL ~ 400

units/mL.

NOTE: 1 endopeptidase activity unit is defined as: at 40°C, when pH8.0, the amount of enzyme required

to hydrolyze 1 μmol of tyrosine from soluble casein (and is soluble in trichloroacetic acid).

1.5.4 Amyloglucosidase solution: cannot contain glycerol as stabilizer, CAS

9032-08-0, IUS 3.2.1.3. Store at 0°C ~ 5°C.

1.5.4.1 Enzyme activity representation 1: Starch/glucose oxidase-peroxidase

method, 2,000 units/mL ~ 3,300 units/mL.

NOTE: 1 endopeptidase activity unit is defined as: at 40°C, when pH4.5, the amount of enzyme required

to release 1 μmol of glucose per minute.

1.5.4.2 Enzyme activity representation 2: p-Nitrophenyl-β-maltoside (PNPBM)

method, 130 units/mL ~ 200 unit /mL.

NOTE: 1 enzyme activity unit is defined as (1 PNP unit): at 40°C, in the presence of excessive β-

glucosidase, the amount of enzyme required to release 1 μmol of p-nitrophenyl from p-nitrophenyl-β-

maltoside per minute.

1.5.5 Pickled diatomite: CAS 68855-54-9. Take 200 g of diatomite in 600 mL of

hydrochloric acid (HCl : H2O = 1:4, volume ratio). Soak overnight. Filter. Use

distilled water to wash until the filtrate is neutral. Place in 525°C ± 5°C muffle

furnace to burn the ash. Leave it for use.

1.5.6 2-(N-morpholino)-sulfonate ethane (MES): CAS 4432-31-9, purity >99.5%.

1.5.7 Trihydroxymethyl aminomethane (TRIS): CAS 77-86-1, purity >99%.

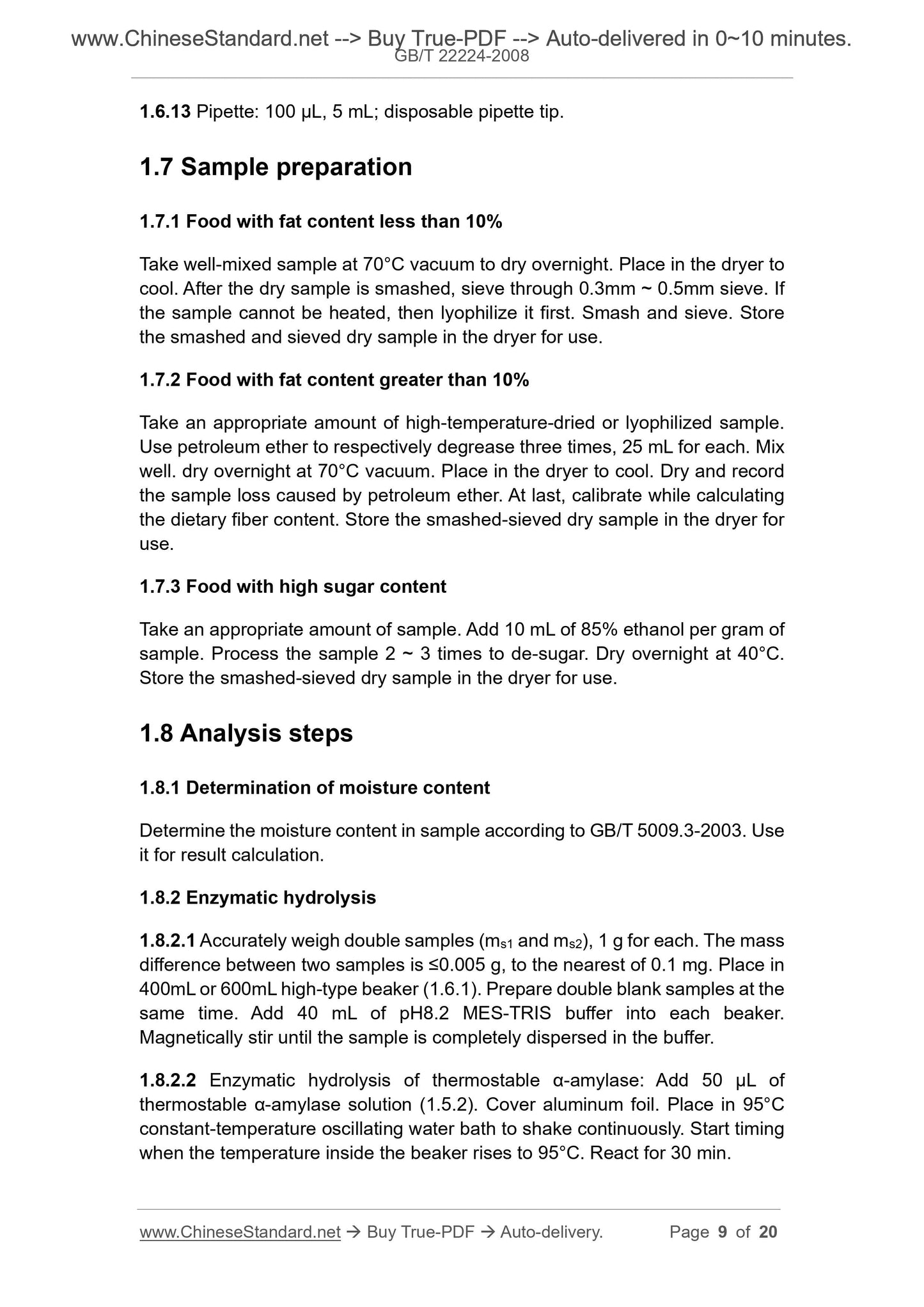

1.6.13 Pipette: 100 µL, 5 mL; disposable pipette tip.

1.7 Sample preparation

1.7.1 Food with fat content less than 10%

Take well-mixed sample at 70°C vacuum to dry overnight. Place in the dryer to

cool. After the dry sample is smashed, sieve through 0.3mm ~ 0.5mm sieve. If

the sample cannot be heated, then lyophilize it first. Smash and sieve. Store

the smashed and sieved dry sample in the dryer for use.

1.7.2 Food with fat content greater than 10%

Take an appropriate amount of high-temperature-dried or lyophilized sample.

Use petroleum ether to respectively degrease three times, 25 mL for each. Mix

well. dry overnight at 70°C vacuum. Place in the dryer to cool. Dry and record

the sample loss caused by petroleum ether. At last, calibrate while calculating

the dietary fiber content. Store the smashed-sieved dry sample in the dryer for

use.

1.7.3 Food with high sugar content

Take an appropriate amount of sample. Add 10 mL of 85% ethanol per gram of

sample. Process the sample 2 ~ 3 times to de-sugar. Dry overnight at 40°C.

Store the smashed-sieved dry sample in the dryer for use.

1.8 Analysis steps

1.8.1 Determination of moisture content

Determine the moisture content in sample according to GB/T 5009.3-2003. Use

it for result calculation.

1.8.2 Enzymatic hydrolysis

1.8.2.1 Accurately weigh double samples (ms1 and ms2), 1 g for each. The mass

difference between two samples is ≤0.005 g, to the nearest of 0.1 mg. Place in

400mL or 600mL high-type beaker (1.6.1). Prepare double blank samples at the

same time. Add 40 mL of pH8.2 MES-TRIS buffer into each beaker.

Magnetically stir until the sample is completely dispersed in the buffer.

1.8.2.2 Enzymatic hydrolysis of thermostable α-amylase: Add 50 µL of

thermostable α-amylase solution (1.5.2). Cover aluminum foil. Place in 95°C

constant-temperature oscillating water bath to shake continuously. Start timing

when the temperature inside the beaker rises to 95°C. React for 30 min.

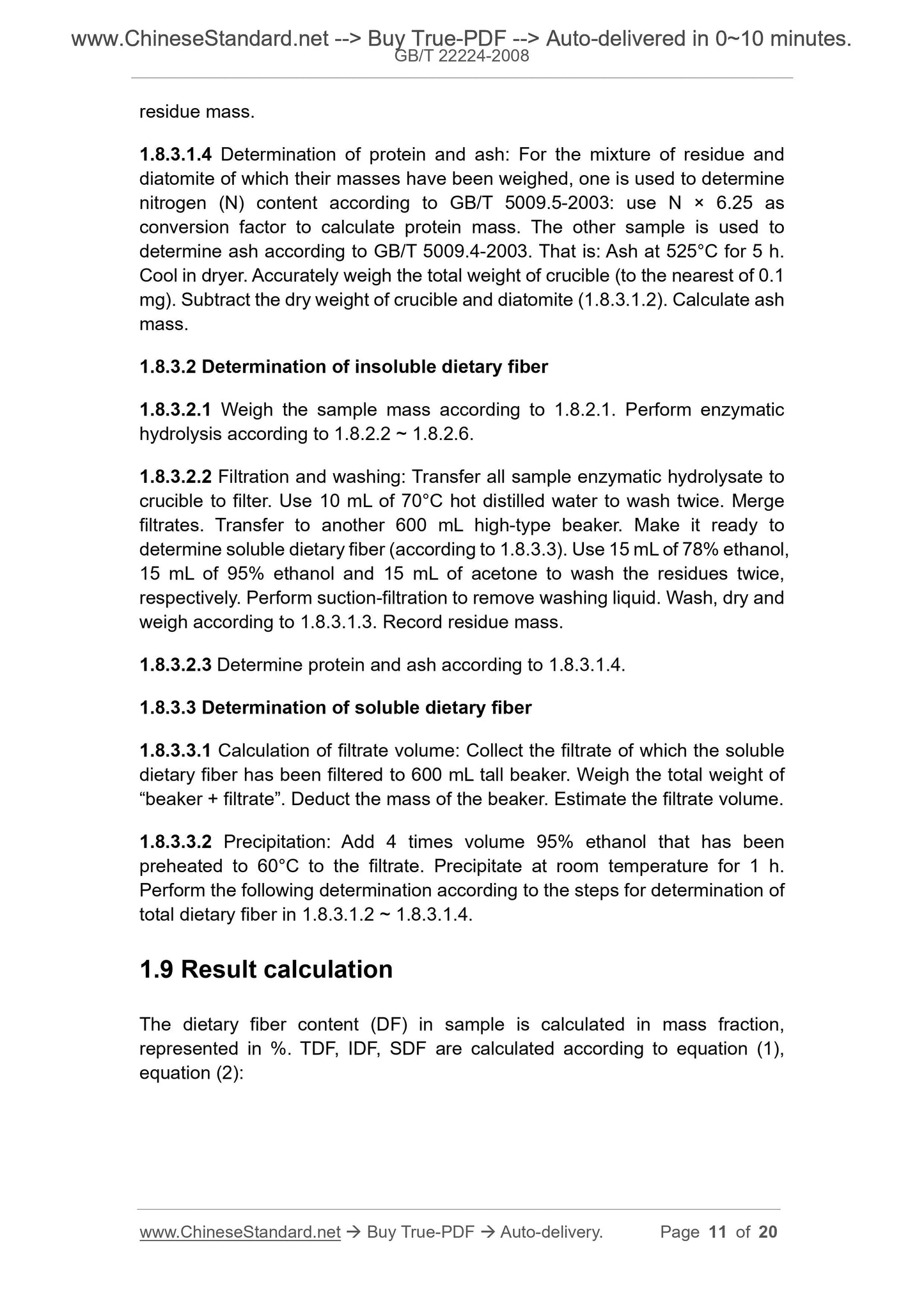

residue mass.

1.8.3.1.4 Determination of protein and ash: For the mixture of residue and

diatomite of which their masses have been weighed, one is used to determine

nitrogen (N) content according to GB/T 5009.5-2003: use N × 6.25 as

conversion factor to calculate protein mass. The other sample is used to

determine ash according to GB/T 5009.4-2003. That is: Ash at 525°C for 5 h.

Cool in dryer. Accurately weigh the total weight of crucible (to the nearest of 0.1

mg). Subtract the dry weight of crucible and diatomite (1.8.3.1.2). Calculate ash

mass.

1.8.3.2 Determination of insoluble dietary fiber

1.8.3.2.1 Weigh the sample mass according to 1.8.2.1. Perform enzymatic

hydrolysis according to 1.8.2.2 ~ 1.8.2.6.

1.8.3.2.2 Filtration and washing: Transfer all sample enzymatic hydrolysate to

crucible to filter. Use 10 mL of 70°C hot distilled water to wash twice. Merge

filtrates. Transfer to another 600 mL high-type beaker. Make it ready to

determine soluble dietary fiber (according to 1.8.3.3). Use 15 mL of 78% ethanol,

15 mL of 95% ethanol and 15 mL of acetone to wash the residues twice,

respectively. Perform suction-filtration to remove washing liquid. Wash, dry and

weigh according to 1.8.3.1.3. Record residue mass.

1.8.3.2.3 Determine protein and ash according to 1.8.3.1.4.

1.8.3.3 Determination of soluble dietary fiber

1.8.3.3.1 Calculation of filtrate volume: Collect the filtrate of which the soluble

dietary fiber has been filtered to 600 mL tall beaker. Weigh the total weight of

“beaker + filtrate”. Deduct the mass of the beaker. Estimate the filtrate volume.

1.8.3.3.2 Precipitation: Add 4 times volume 95% ethanol that has been

preheated to 60°C to the filtrate. Precipitate at room temperature for 1 h.

Perform the following determination according to the steps for determination of

total dietary fiber in 1.8.3.1.2 ~ 1.8.3.1.4.

1.9 Result calculation

The dietary fiber content (DF) in sample is calculated in mass fraction,

represented in %. TDF, IDF, SDF are calculated according to equation (1),

equation (2):

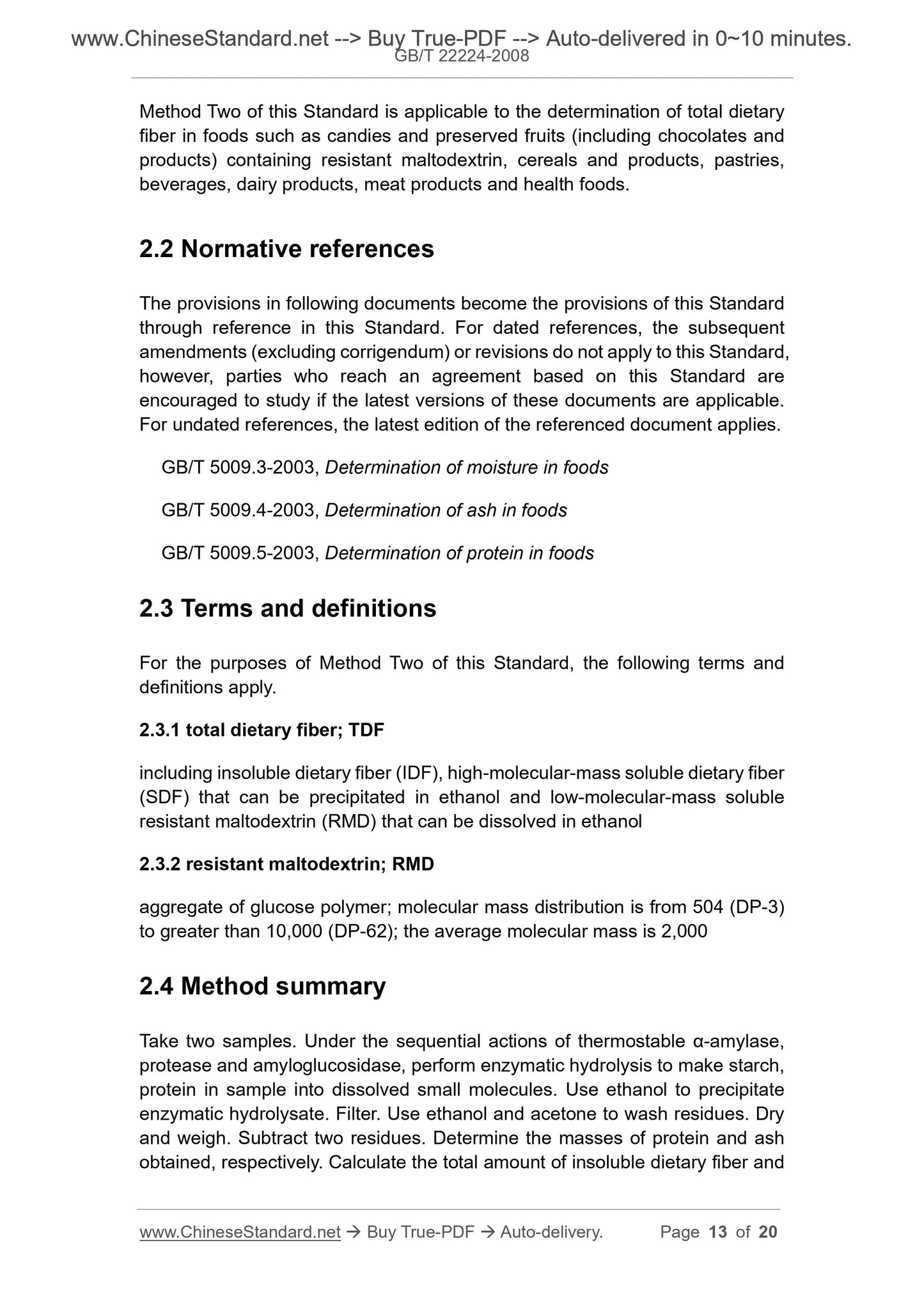

Method Two of this Standard is applicable to the determination of total dietary

fiber in foods such as candies and preserved fruits (including chocolates and

products) containing resistant maltodextrin, cereals and products, pastries,

beverages, dairy products, meat products and health foods.

2.2 Normative references

The provisions in following documents become the provisions of this Standard

through reference in this Standard. For dated references, the subsequent

amendments (excluding corrigendum) or revisions do not apply to this Standard,

however, parties who reach an agreement based on this Standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

GB/T 5009.3-2003, Determination of moisture in foods

GB/T 5009.4-2003, Determination of ash in foods

GB/T 5009.5-2003, Determination of protein in foods

2.3 Terms and definitions

For the purposes of Method Two of this Standard, the following terms and

definitions apply.

2.3.1 total dietary fiber; TDF

including insoluble dietary fiber (IDF), high-molecular-mass soluble dietary fiber

(SDF) that can be precipitated in ethanol and low-molecular-mass soluble

resistant maltodextrin (RMD) that can be dissolved in ethanol

2.3.2 resistant maltodextrin; RMD

aggregate of glucose polymer; molecular mass distribution is from 504 (DP-3)

to greater than 10,000 (DP-62); the average molecular mass is 2,000

2.4 Method summary

Take two samples. Under the sequential actions of thermostable α-amylase,

protease and amyloglucosidase, perform enzymatic hydrolysis to make starch,

protein in sample into dissolved small molecules. Use ethanol to precipitate

enzymatic hydrolysate. Filter. Use ethanol and acetone to wash residues. Dry

and weigh. Subtract two residues. Determine the masses of protein and ash

obtained, respectively. Calculate the total amount of insoluble dietary fiber and

2.6.14 Glass column: Length is 75 mm. Inner diameter is 15 mm. Lower end

has No. 1 sand core. It is equipped with polytetrafluoro cock.

2.6.15 Rotary evaporator.

2.6.16 High performance liquid chromatography: equipped with differential

detector (RID).

2.6.17 Gel protection column: 6.0 mm × 40 mm, 6 μm.

2.6.18 Gel chromatographic column: 7.8 mm × 300 mm, 6 μm; two pieces.

2.7 Sample preparation

2.7.1 Same with 1.7.1 of Method One.

2.7.2 Same with 1.7.2 of Method One. But the foods that contain high sugar

content may not be de-sugared.

2.8 Analysis steps

2.8.1 Determination of moisture content

Same with 1.8.1 of Method One.

2.8.2 Enzymatic hydrolysis

2.8.2.1 Same with 1.8.2.1 of Method One.

2.8.2.2 Same with 1.8.2.2 of Method One. The amount of thermostable α-

amylase used is 100 μL.

2.8.2.3 Same with 1.8.2.3 of Method One.

2.8.2.4 Same with 1.8.2.4 of Method One.

2.8.2.5 Same with 1.8.2.5 of Method One.

2.8.2.6 Same with 1.8.2.6 of Method One. The amount of amyloglucosidase

used is 300 μL.

2.8.3 Enzymatic gravimetric method

It is used to determine the total content of insoluble dietary fiber (IDF) and high-

molecular-mass soluble dietary fiber (SDF).

2.8.3.1 Precipitation: same with 1.8.3.1.1.

2.8.3.2 Filtration: same with 1.8.3.1.2.

2.8.3.3 Washing: Use 20 mL of 78% ethanol to wash high-type beaker 3 times.

Under vacuum conditions, wash off the residues in crucible. Use 20 mL of 78%

ethanol that have been used to wash the beaker to wash 3 times; use 10 mL of

95% ethanol to wash twice; use 10 mL of acetone to rinse twice, in sequence.

Add 10 mL of internal standard solution (2.5.18) into the filtrate. Then use 78%

ethanol solution to set volume to 500 mL. Mix well.

2.8.3.4 Concentration: Take 200 mL of filtrate to perform rotary evaporation at

50°C to nearly dry. Use distilled water to set volume to 50 mL.

2.8.3.5 Weighing: Place the crucible at 70°C vacuum overnight. Weigh the

masses of crucible, dietary fiber residue and diatomite, to the nearest of 0.1 mg.

Subtract the masses of crucible and diatomite in 2.8.3.2. Calculate the mass of

residues that contain insoluble dietary fiber (IDF) and high-molecular-mass

soluble dietary fiber (SDF) that can be precipitated in ethanol.

2.8.3.6 Determination of ash: Take one residue from double samples.

Determine the ash in the sample according to GB/T 5009.4-2003.

2.8.3.7 Determination of protein: Take the other residue from double samples.

Determine the protein content in the sample according to GB/T 5009.5-2003.

2.8.4 Liquid chromatography

Use high performance liquid chromatography to determine the content of low-

molecular-mass of resistant maltodextrin in sample.

2.8.4.1 Desalting

Add 10 g of well-swollen and completely-mixed OH-type polyamine-based

weak-alkaline ion-exchange resin (2.5.16) and 10 g of Na-type macroporous

strong-acid styrene cation exchange resin (2.5.17) that has been converted to

H-type INTO the glass column (2.6.14). First, use 100 mL of water to clean.

Then add 50 mL of solution in 2.8.3.4 into the column. Use 100 mL of water to

elute. The flow rate is 0.8 mL/min. Collect 150 mL of eluent. Perform rotary

evaporation at 50°C to nearly dry. Add a small amount of water to transfer it out.

Set volume to 25 mL. The solution is filtered through 0.45μm aqueous

membrane. Make it ready for liquid chromatography analysis.

2.8.4.2 Determination

2.8.4.2.1 Chromatographic reference conditions

Chromatographic column: gel protection column (6.0 mm × 40 mm, 6 μm); two

series-connected gel columns (7.8 mm × 300 mm, 6 μm).

Basic Data

| Standard ID | GB/T 22224-2008 (GB/T22224-2008) |

| Description (Translated English) | Determination of dietary fiber in foods -- Enzymatic gravimetric method and enzymatic gravimetric method -- Liquid chromatography |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | X04 |

| Classification of International Standard | 67.050 |

| Word Count Estimation | 12,138 |

| Date of Issue | 2008-05-16 |

| Date of Implementation | 2008-10-01 |

| Quoted Standard | GB/T 5009.3-2003; GB/T 5009.4-2003; GB/T 5009.5-2003 |

| Adopted Standard | AOAC 991.43-2000, MOD; AOAC 2001.03-2004, MOD |

| Regulation (derived from) | National Standard Approval Announcement 2008 No.10 (Total No.123) |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the enzyme-Determination of the weight of food in total, conditions of soluble and insoluble dietary fiber and a detailed analysis of the steps. The first method is suitable for standard cereals, vegetables and fruits and their products in the total, determination of soluble and insoluble dietary fiber. But not for resistant maltodextrin -containing low molecular mass, oligofructose, galacto, measured polydextrose and resistant starch, dietary fiber foods. |

Share