1

/

of

7

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 21840-2008 English PDF (GB/T21840-2008)

GB/T 21840-2008 English PDF (GB/T21840-2008)

Regular price

$130.00

Regular price

Sale price

$130.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 21840-2008: Vulcanizing accelerator TBBS

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 21840-2008 (Self-service in 1-minute)

Newer / historical versions: GB/T 21840-2008

Preview True-PDF

Scope

This Standard specifies the requirements, test methods, inspection rules, marks,packaging, transportation and storage for N-tert-butyl-2-benzothiazole sulfenamide

(vulcanizing accelerator TBBS).

This Standard is applicable to vulcanizing accelerator TBBS made by oxidation of tert-

butylamine and vulcanizing accelerator MBT.

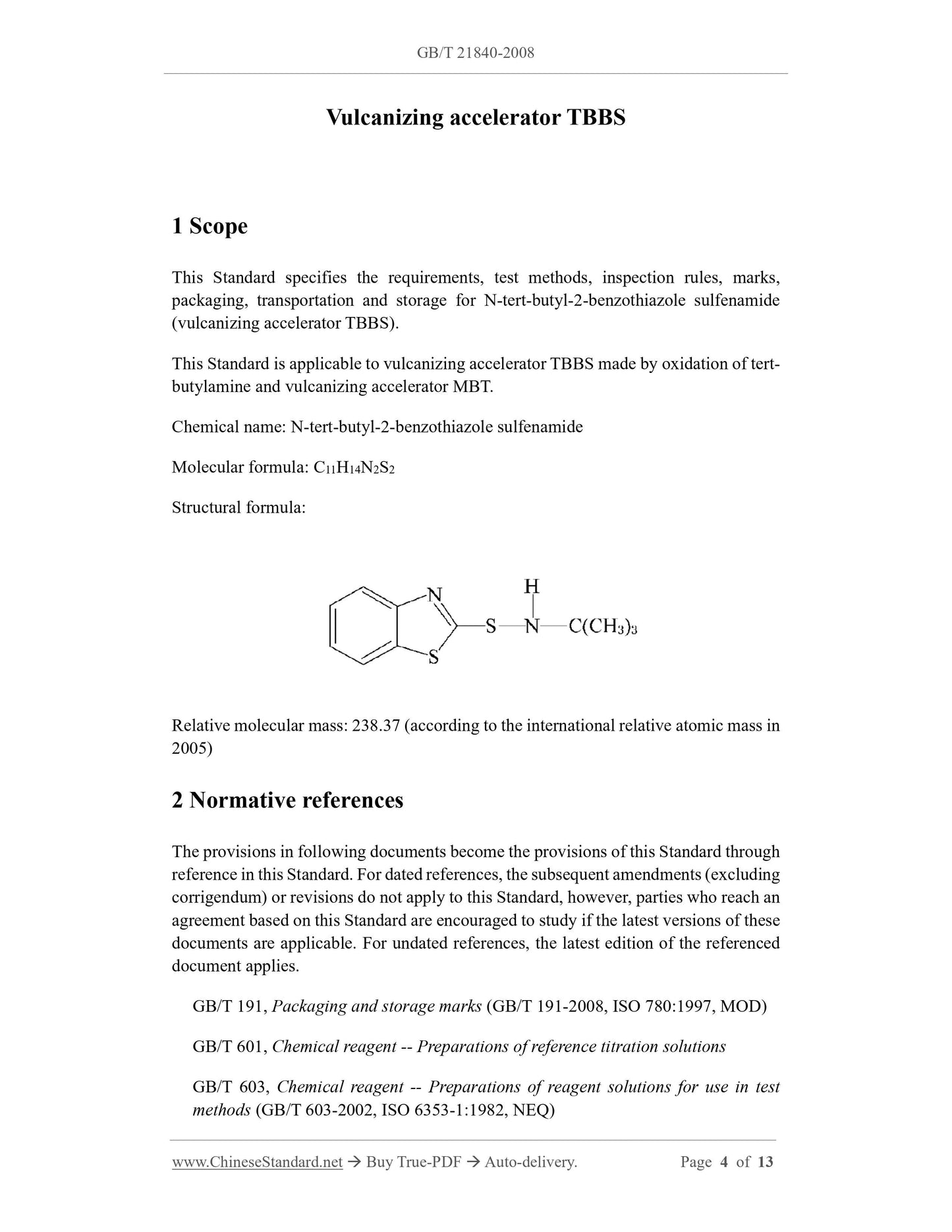

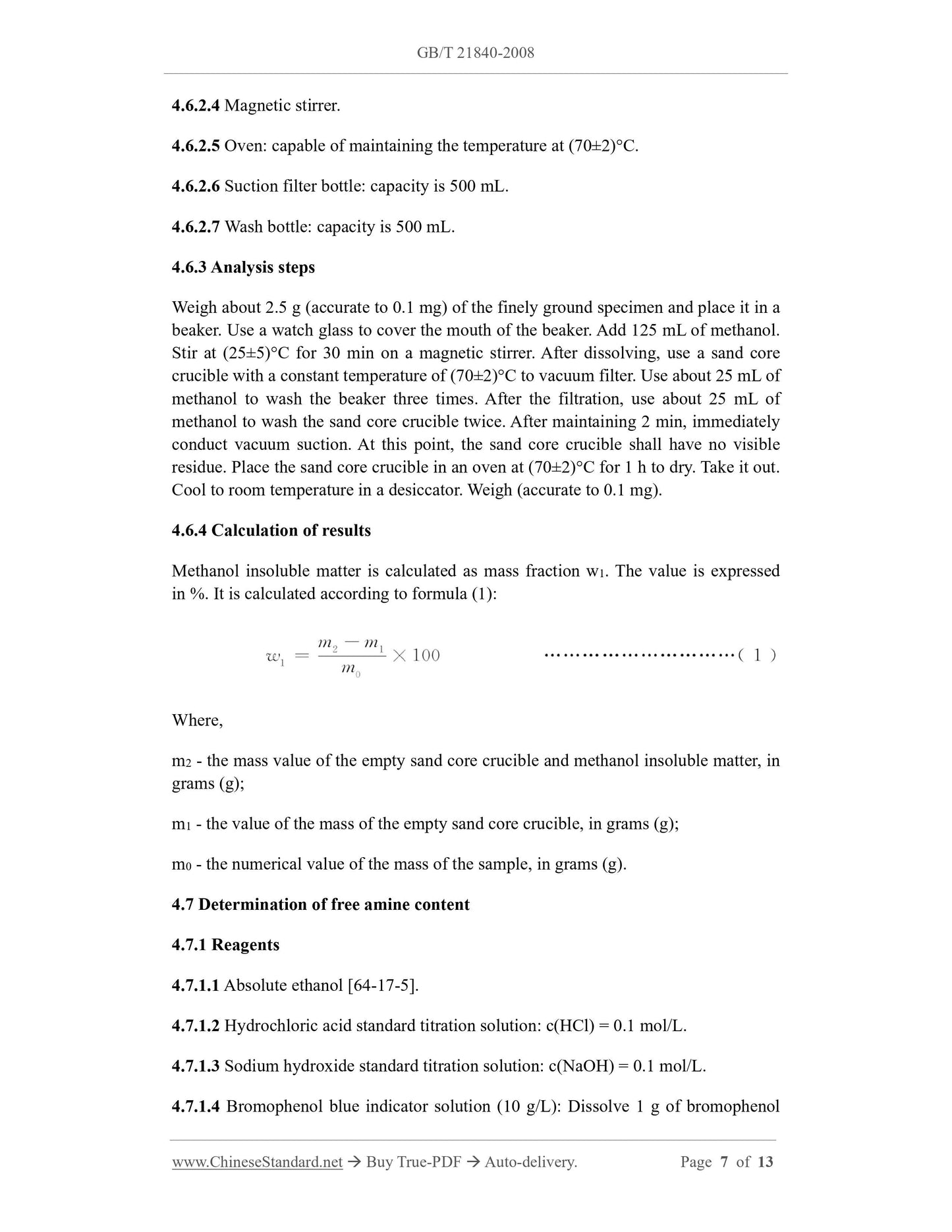

Chemical name: N-tert-butyl-2-benzothiazole sulfenamide

Molecular formula: C11H14N2S2

Structural formula:

Relative molecular mass: 238.37 (according to the international relative atomic mass in

2005)

Basic Data

| Standard ID | GB/T 21840-2008 (GB/T21840-2008) |

| Description (Translated English) | Vulcanizing accelerator TBBS |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | G71 |

| Classification of International Standard | 83.040.20 |

| Word Count Estimation | 9,990 |

| Date of Issue | 2008-05-15 |

| Date of Implementation | 2008-11-01 |

| Quoted Standard | GB/T 191; GB/T 601; GB/T 603; GB/T 1250; GB/T 6003.1; GB/T 6679; GB/T 6682; GB/T 11409.1; GB/T 11409.4; GB/T 11409.5-1989; GB/T 11409.7 |

| Adopted Standard | JIS K6220-2-2001, NEQ |

| Regulation (derived from) | National Standard Approval Announcement 2008 No.8 (Total No.121) |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the N- tert -butyl-2-benzothiazole sulfenamide requirements, test methods, inspection rules, signs, packaging, transport and storage. This standard applies to the tertiary amine, vulcanization vulcanization accelerator MBT made ??by oxidation accelerator TBBS. |

Share