1

/

of

7

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 21833.1-2020 English PDF (GB/T21833.1-2020)

GB/T 21833.1-2020 English PDF (GB/T21833.1-2020)

Regular price

$195.00

Regular price

Sale price

$195.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 21833.1-2020: Seamless austenitic-ferritic (duplex) stainless steel tubes and pipes - Part 1: Tubes for heat exchanger

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 21833.1-2020 (Self-service in 1-minute)

Newer / historical versions: GB/T 21833.1-2020

Preview True-PDF

Scope

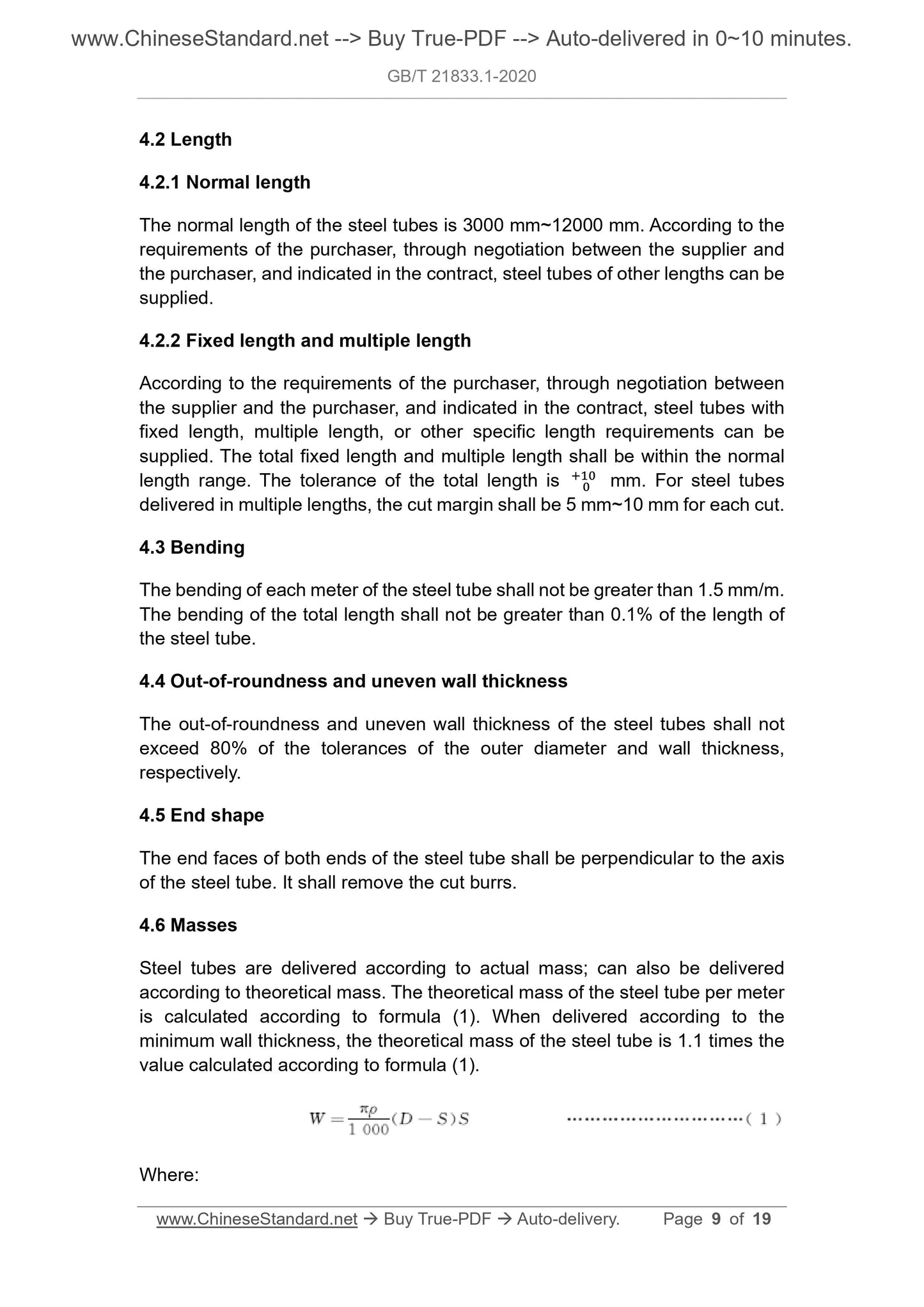

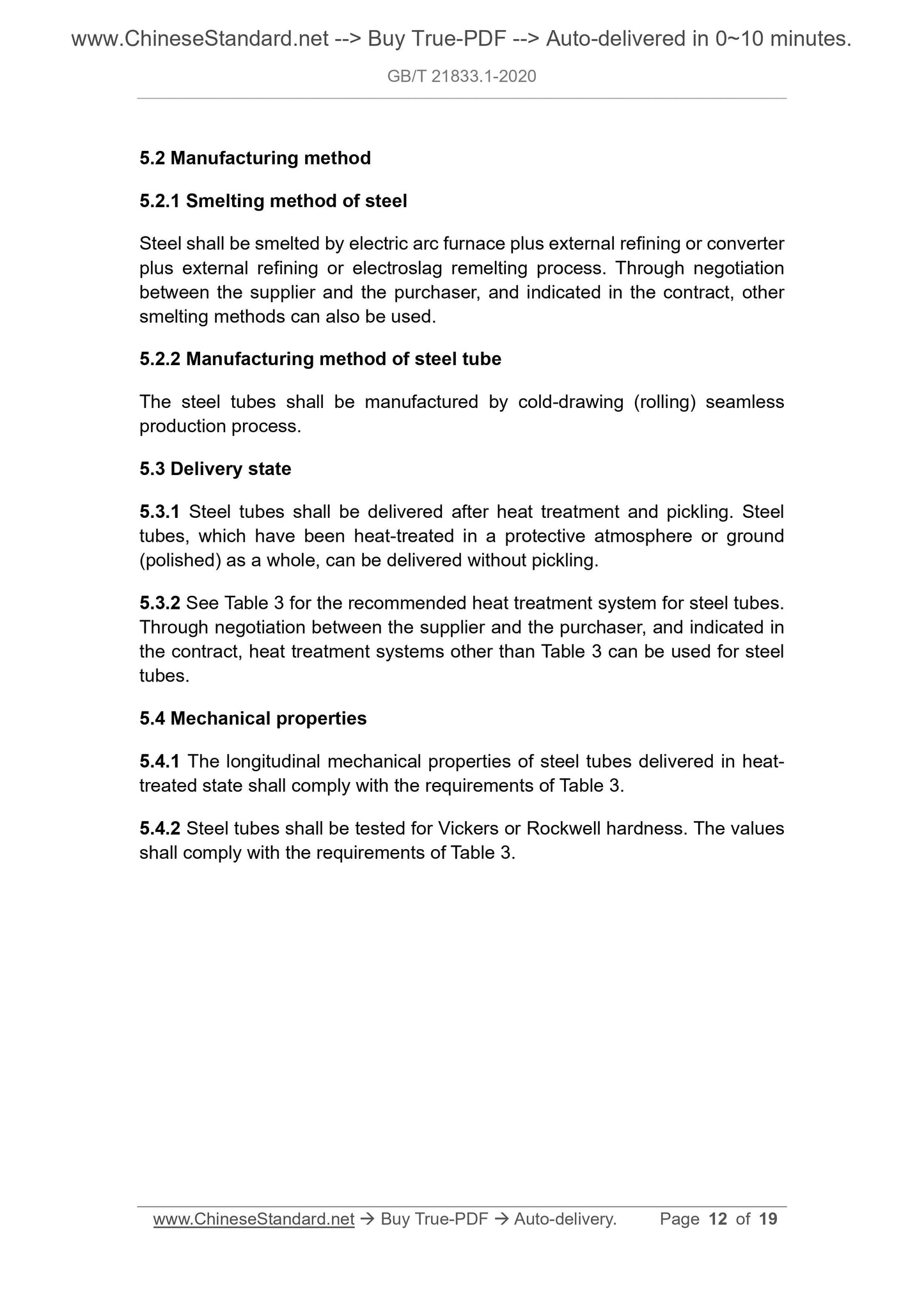

This Part of GB/T 21833 specifies the order content, dimensions, shapes,masses, technical requirements, test methods, inspection rules, packing,

marking, and quality certification of seamless austenitic-ferritic (duplex)

stainless steel tubes and pipes for heat exchanger.

This Part applies to seamless austenitic-ferritic (duplex) stainless steel tubes

and pipes for heat exchanger (hereinafter referred to as steel tubes).

Basic Data

| Standard ID | GB/T 21833.1-2020 (GB/T21833.1-2020) |

| Description (Translated English) | Seamless austenitic-ferritic (duplex) stainless steel tubes and pipes - Part 1: Tubes for heat exchanger |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | H48 |

| Classification of International Standard | 77.140.75 |

| Word Count Estimation | 14,171 |

| Date of Issue | 2020-04-28 |

| Date of Implementation | 2020-11-01 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share