1

/

of

8

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 21707-2018 English PDF (GB/T21707-2018)

GB/T 21707-2018 English PDF (GB/T21707-2018)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 21707-2018: Insulation specification for variable frequency adjustable speed definite purpose converter-fed three-phase induction motors

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 21707-2018 (Self-service in 1-minute)

Newer / historical versions: GB/T 21707-2018

Preview True-PDF

Scope

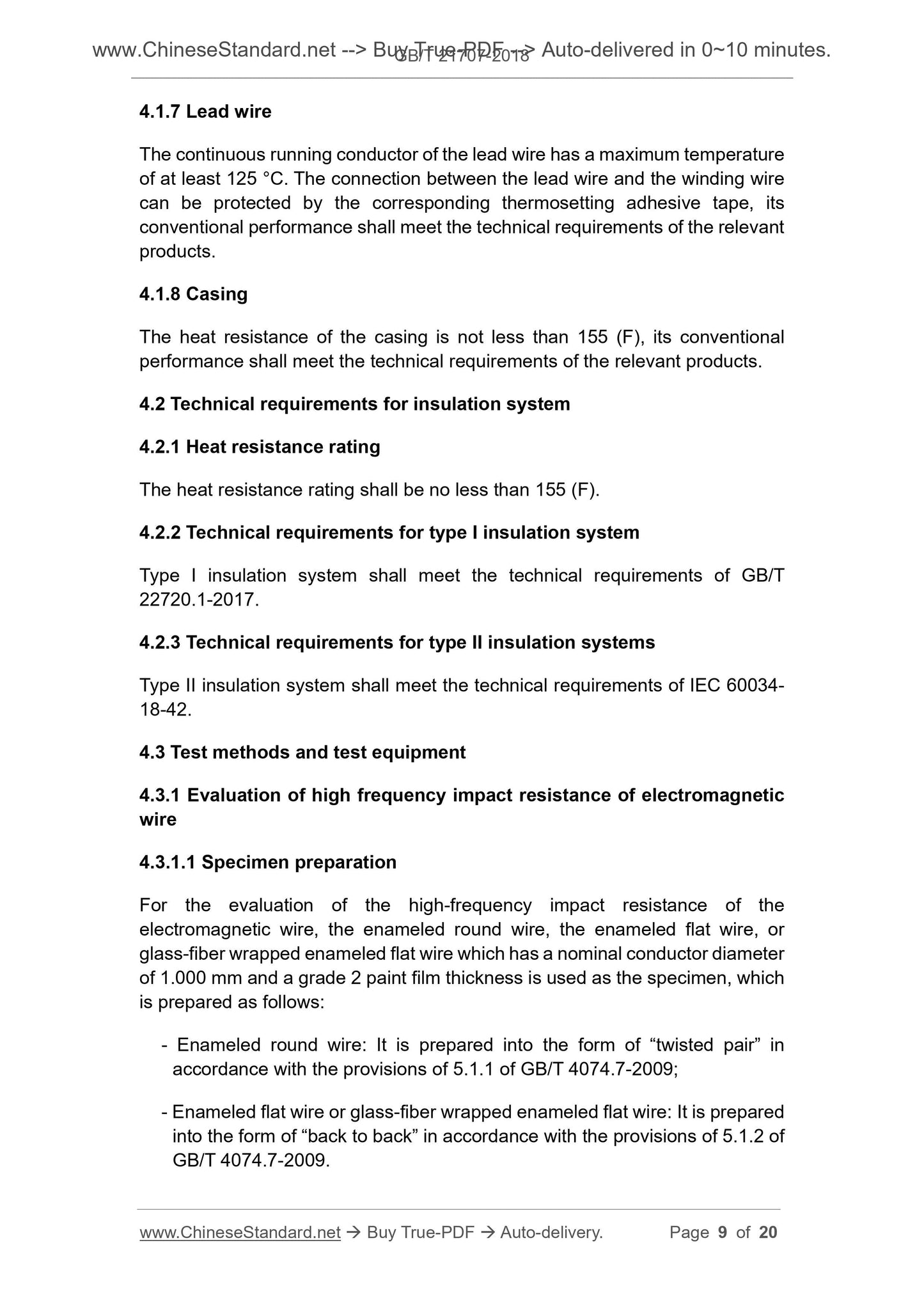

This standard gives the insulation specifications for variable frequencyadjustable speed definite purpose converter-fed three-phase induction motors,

including terms and definitions, technical requirements and inspection rules.

This standard is applicable to variable frequency adjustable speed definite

purpose converter-fed three-phase induction motors with rated voltage of 1140

V and below.

Basic Data

| Standard ID | GB/T 21707-2018 (GB/T21707-2018) |

| Description (Translated English) | Insulation specification for variable frequency adjustable speed definite purpose converter-fed three-phase induction motors |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | K20 |

| Classification of International Standard | 29.160.01 |

| Word Count Estimation | 14,114 |

| Date of Issue | 2018-06-07 |

| Date of Implementation | 2019-01-01 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share