1

/

of

9

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 20125-2006 English PDF (GB/T20125-2006)

GB/T 20125-2006 English PDF (GB/T20125-2006)

Regular price

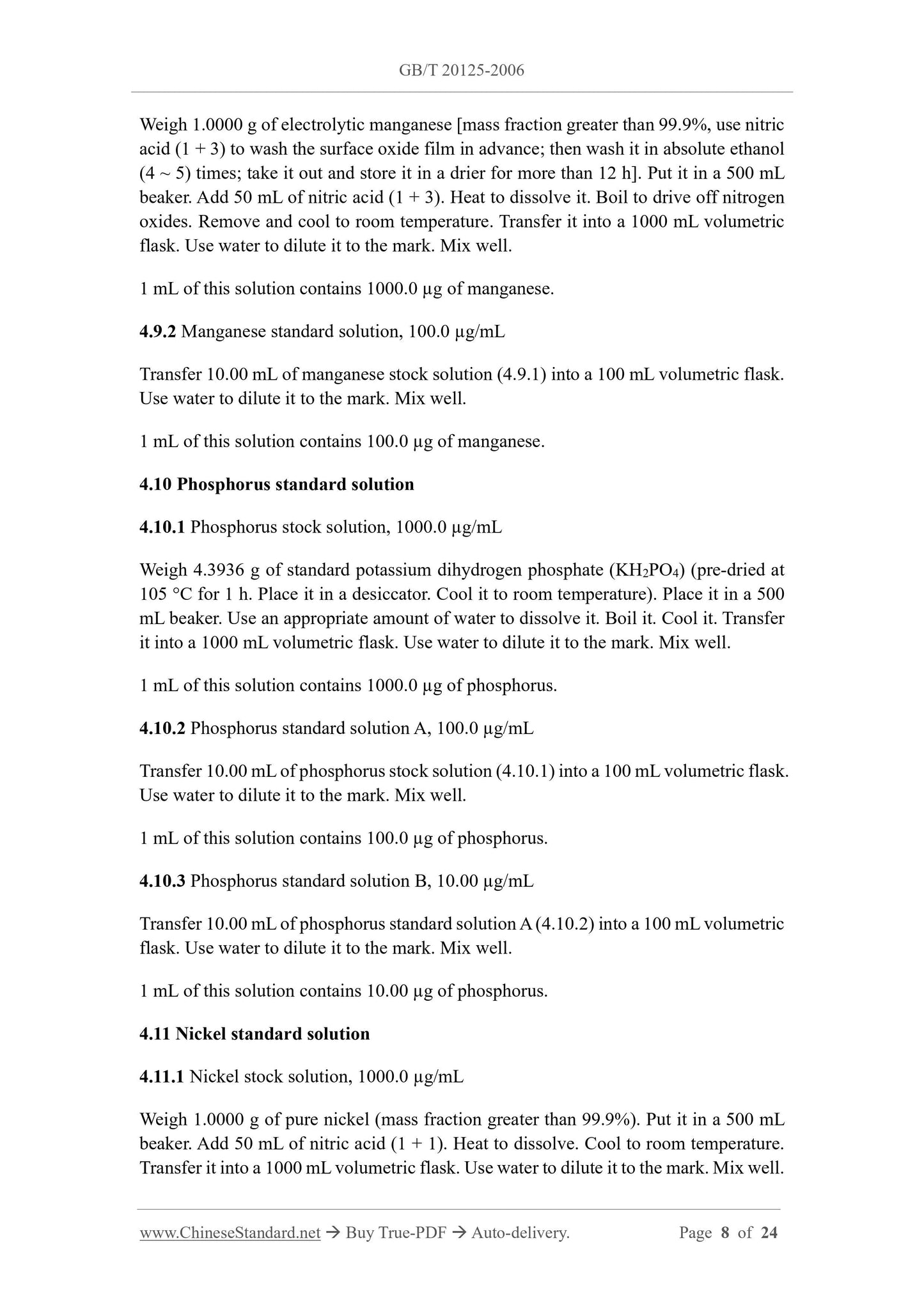

$155.00

Regular price

Sale price

$155.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 20125-2006: Low-alloy steel -- Determination of multi-element contents -- Inductively coupled plasma atomic emission spectrometric method

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 20125-2006 (Self-service in 1-minute)

Newer / historical versions: GB/T 20125-2006

Preview True-PDF

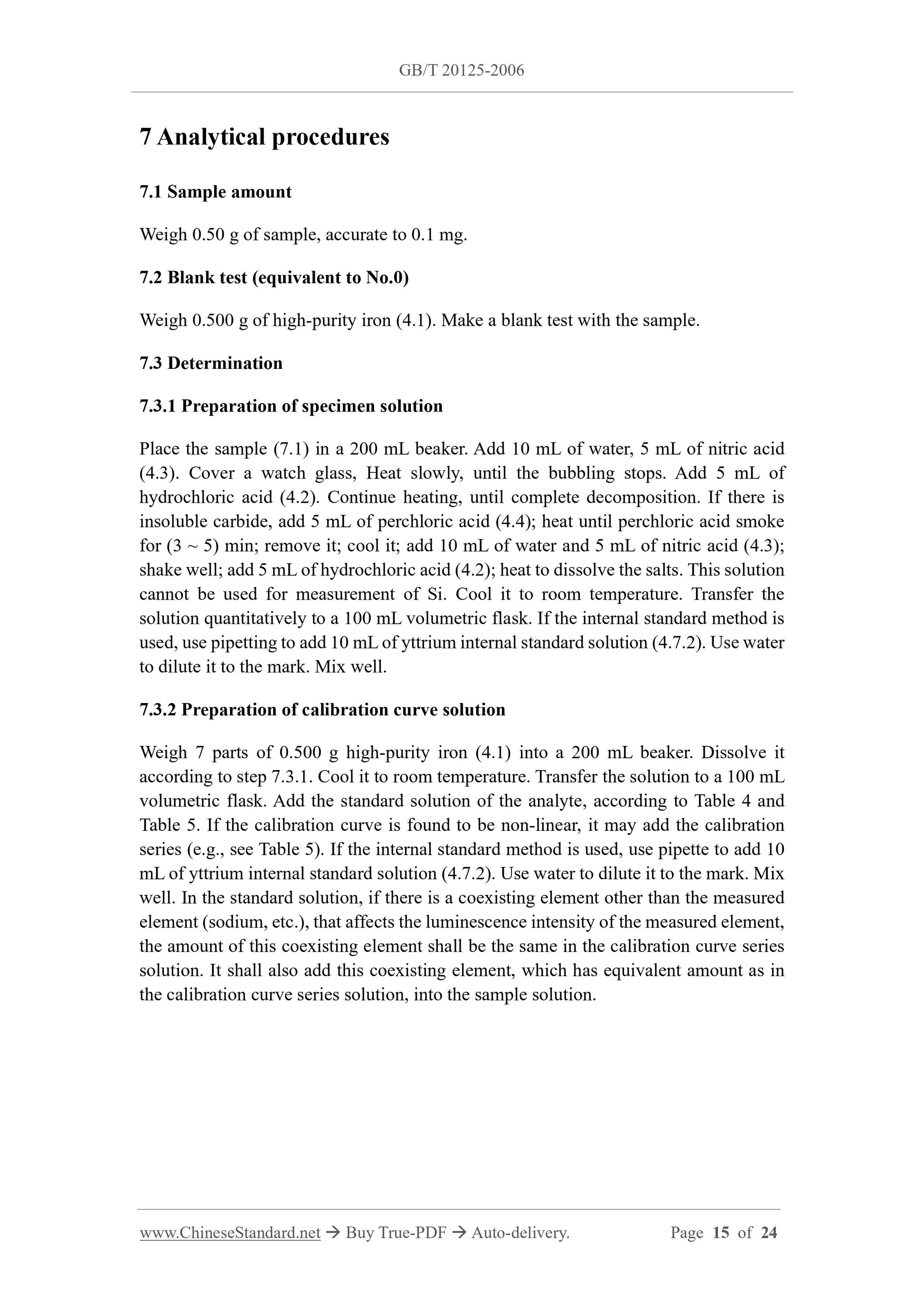

Scope

This standard specifies the method for the determination of silicon, manganese,phosphorus, nickel, chromium, molybdenum, copper, vanadium, cobalt, titanium,

aluminum, by inductively coupled plasma emission spectrometry.

This method is suitable for the determination of silicon, manganese, phosphorus, nickel,

chromium, molybdenum, copper, vanadium, cobalt, titanium, aluminum in carbon steel

and low alloy steel, which has an iron mass fraction greater than 92%. For the

determination range of multi-elements, refer to Table 1.

The silicon, titanium, aluminum, which is measured by this method, are acid-soluble

silicon, acid-soluble titanium, acid-soluble aluminum.

When even only one of the components in the steel exceeds the upper limit of the

content range in Table 1, this standard does not apply.

In steel, when the mass fraction of carbon and sulfur is greater than 1.0%, AND the

mass fraction of tungsten and niobium is greater than 0.10%, this standard is also not

applicable.

Basic Data

| Standard ID | GB/T 20125-2006 (GB/T20125-2006) |

| Description (Translated English) | Low-alloy steel -- Determination of multi-element contents -- Inductively coupled plasma atomic emission spectrometric method |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | H11 |

| Classification of International Standard | 77.080.20 |

| Word Count Estimation | 16,131 |

| Date of Issue | 2006-03-02 |

| Date of Implementation | 2006-09-01 |

| Quoted Standard | GB/T 20066-2006; GB/T 6379 |

| Adopted Standard | JIS G1258-1989, MOD |

| Regulation (derived from) | China National Standard Approval Announcement 2006 No.3 (Total No.90) |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the determination of silicon by inductively coupled plasma atomic emission spectrometry, manganese, phosphorus, Nickel, Aluminum methods, titanium, vanadium, , cobalt chromium, molybdenum, copper. This method is suitable for the mass fraction of greater than 92% iron carbon steel, low alloy silicon, manganese, phosphorus, Nickel, chromium, molybdenum, copper, vanadium, Determination of aluminum content, cobalt, titanium. Multi-element determination of the scope of its contents are shown in Table 1. The method for the determination of silicon, titanium and aluminum as acid soluble silicon, acid-soluble titanium and Als. When the steel components even if there is only one component of content beyond the upper limit of the range in Table 1, this standard does not apply. Carbon steel, sulfur content greater than 1. 0%, tungsten, niobium content greater than 0. 10%, the standard does not apply. This standard specifies two alternative methods to determine the content of selected elements in the test solution, using an internal standard, and the other without using an internal standard. |

Share