1

/

of

7

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 19981.2-2014 English PDF (GB/T19981.2-2014)

GB/T 19981.2-2014 English PDF (GB/T19981.2-2014)

Regular price

$85.00

Regular price

Sale price

$85.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

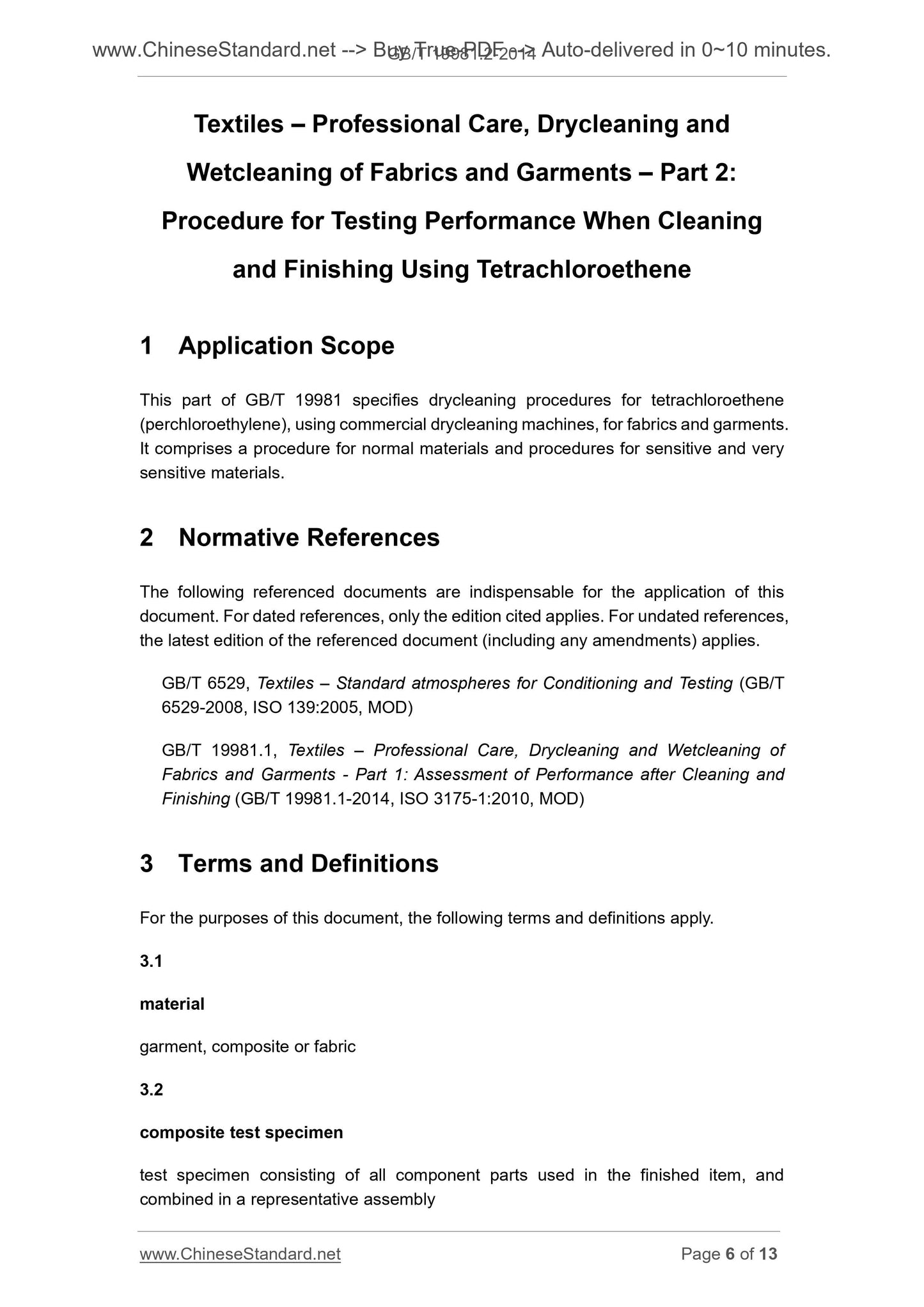

GB/T 19981.2-2014: Textiles -- Professional care, dry cleaning and wet cleaning of fabrics and garments -- Part 2: Procedure for testing performance when dry cleaning and finishing using tetrachloroethene

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 19981.2-2014 (Self-service in 1-minute)

Newer / historical versions: GB/T 19981.2-2014

Preview True-PDF

Scope

This part of GB/T 19981 specifies drycleaning procedures for tetrachloroethene(perchloroethylene), using commercial drycleaning machines, for fabrics and garments.

It comprises a procedure for normal materials and procedures for sensitive and very

sensitive materials.

Basic Data

| Standard ID | GB/T 19981.2-2014 (GB/T19981.2-2014) |

| Description (Translated English) | Textiles -- Professional care, dry cleaning and wet cleaning of fabrics and garments -- Part 2: Procedure for testing performance when dry cleaning and finishing using tetrachloroethene |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | W04 |

| Classification of International Standard | 59.080.30 |

| Word Count Estimation | 10,151 |

| Date of Issue | 12/31/2014 |

| Date of Implementation | 8/1/2015 |

| Older Standard (superseded by this standard) | GB/T 19981.2-2005 |

| Quoted Standard | GB/T 6529; GB/T 19981.1 |

| Adopted Standard | ISO 3175-2-2010, MOD |

| Regulation (derived from) | National Standards Bulletin 2014 No. 33 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This Standard specifies the use of commercial cleaning machines and tetrachlorethylene (perchlorethylene) for dry cleaning fabrics and clothing programs. Including ordinary dry-cleaning program material, sensitive material and Temin material dry cleaning |

Share