1

/

of

8

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 18684-2002 English PDF (GB/T18684-2002)

GB/T 18684-2002 English PDF (GB/T18684-2002)

Regular price

$70.00

Regular price

Sale price

$70.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

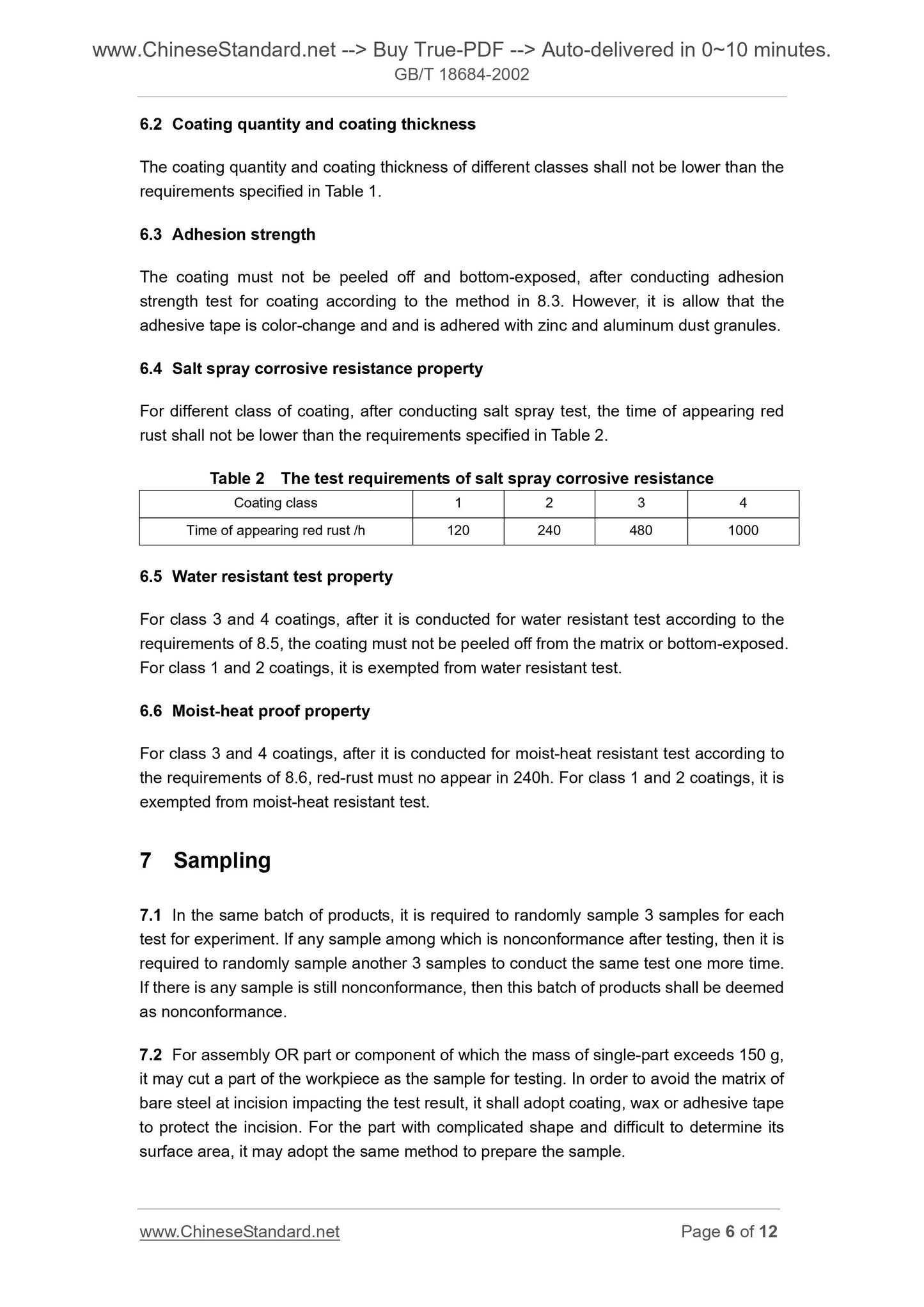

GB/T 18684-2002: Specifications of zinc/chromate coating

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 18684-2002 (Self-service in 1-minute)

Newer / historical versions: GB/T 18684-2002

Preview True-PDF

Scope

This Standard specifies the technical requirements and test methods of zinc/chromatecoatings of steel parts and components.

Basic Data

| Standard ID | GB/T 18684-2002 (GB/T18684-2002) |

| Description (Translated English) | Specifications of zinc/chromate coating |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | A29 |

| Classification of International Standard | 25.220.20 |

| Word Count Estimation | 8,871 |

| Date of Issue | 2002-03-10 |

| Date of Implementation | 2002-08-01 |

| Quoted Standard | GB/T 5270-1985; GB/T 6462; GB/T 10125-1997 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People Republic of China |

| Summary | This standard specifies the steel parts, components, zinc chromate coating on the technical requirements and test methods. |

Share