1

/

of

12

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 18254-2002 English PDF (GB/T18254-2002)

GB/T 18254-2002 English PDF (GB/T18254-2002)

Regular price

$85.00

Regular price

Sale price

$85.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 18254-2002: High-carbon chromium bearing steel

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 18254-2002 (Self-service in 1-minute)

Newer / historical versions: GB/T 18254-2002

Preview True-PDF

Scope

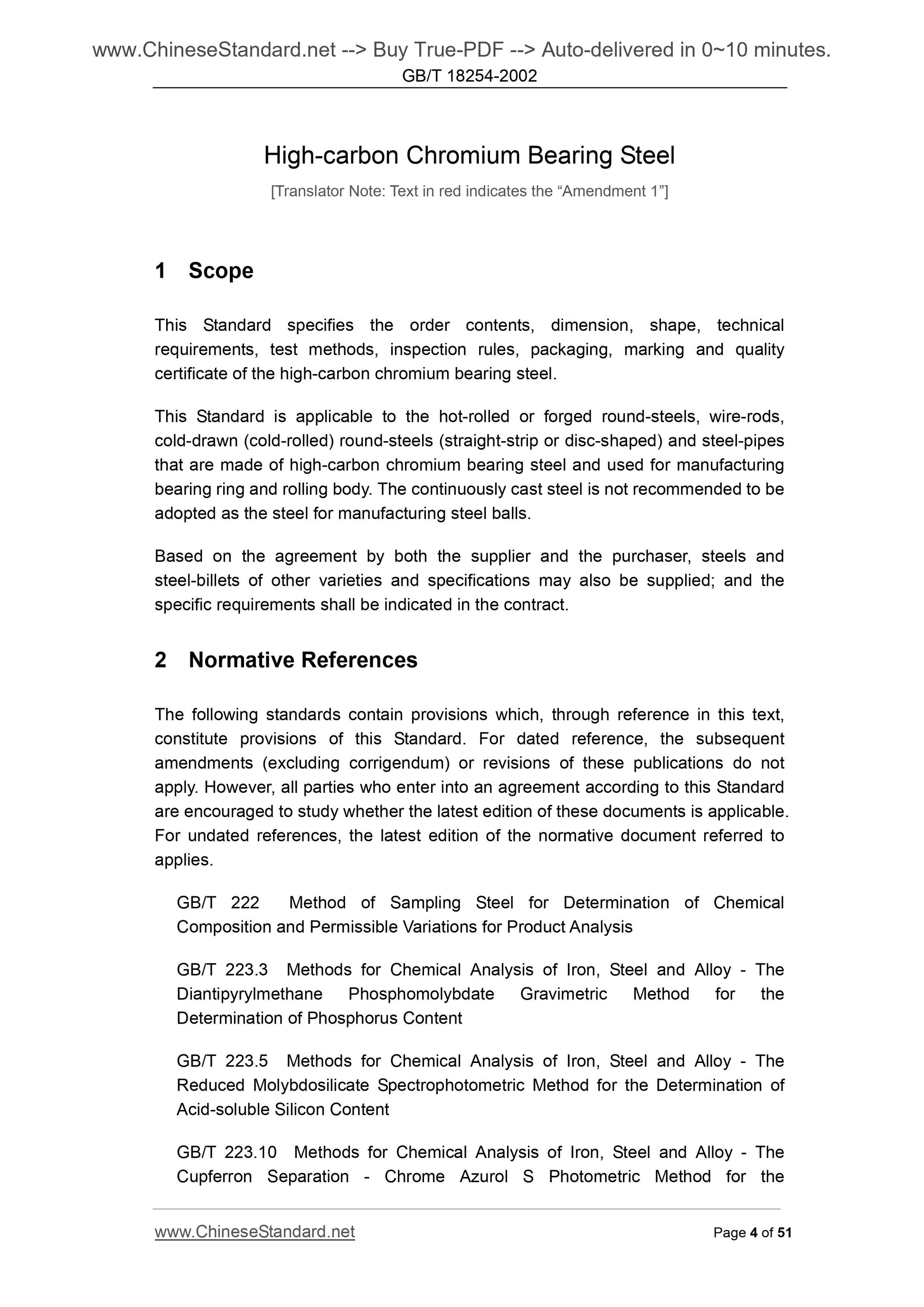

This Standard specifies the order contents, dimension, shape, technicalrequirements, test methods, inspection rules, packaging, marking and quality

certificate of the high-carbon chromium bearing steel.

This Standard is applicable to the hot-rolled or forged round-steels, wire-rods,

cold-drawn (cold-rolled) round-steels (straight-strip or disc-shaped) and steel-pipes

that are made of high-carbon chromium bearing steel and used for manufacturing

bearing ring and rolling body. The continuously cast steel is not recommended to be

adopted as the steel for manufacturing steel balls.

Based on the agreement by both the supplier and the purchaser, steels and

steel-billets of other varieties and specifications may also be supplied; and the

specific requirements shall be indicated in the contract.

Basic Data

| Standard ID | GB/T 18254-2002 (GB/T18254-2002) |

| Description (Translated English) | High-carbon chromium bearing steel |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | H40 |

| Classification of International Standard | 77.140.20 |

| Word Count Estimation | 56,520 |

| Date of Issue | 3/10/2002 |

| Date of Implementation | 7/1/2002 |

| Older Standard (superseded by this standard) | GB/T 18254-2000 |

| Quoted Standard | GB/T 222; GB/T 223.3; GB/T 223.5; GB/T 223.10 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People Republic of China |

| Summary | This Standard specifies the contents of the order of high carbon chromium bearing steel, size, shape, technical requirements, test methods, inspection rules, packaging, marking and quality certification. This Standard is applicable to the production of bearing rings and rolling elements with a high carbon chromium bearing steel hot-rolled or forged steel bar, wire rod, cold drawn (rolled) round (straight or plate) and steel pipe. Continuous casting of steel balls do not recommend. Agreed between, also can supply other varieties and specifications of steel billet, specific requirements should be specified in the contract. |

Share