1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 17600.2-1998 English PDF (GB/T17600.2-1998)

GB/T 17600.2-1998 English PDF (GB/T17600.2-1998)

Regular price

$90.00

Regular price

Sale price

$90.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 17600.2-1998: Steel. Conversion of elongation values. Part 2: Austenitic steels

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 17600.2-1998 (Self-service in 1-minute)

Newer / historical versions: GB/T 17600.2-1998

Preview True-PDF

Scope

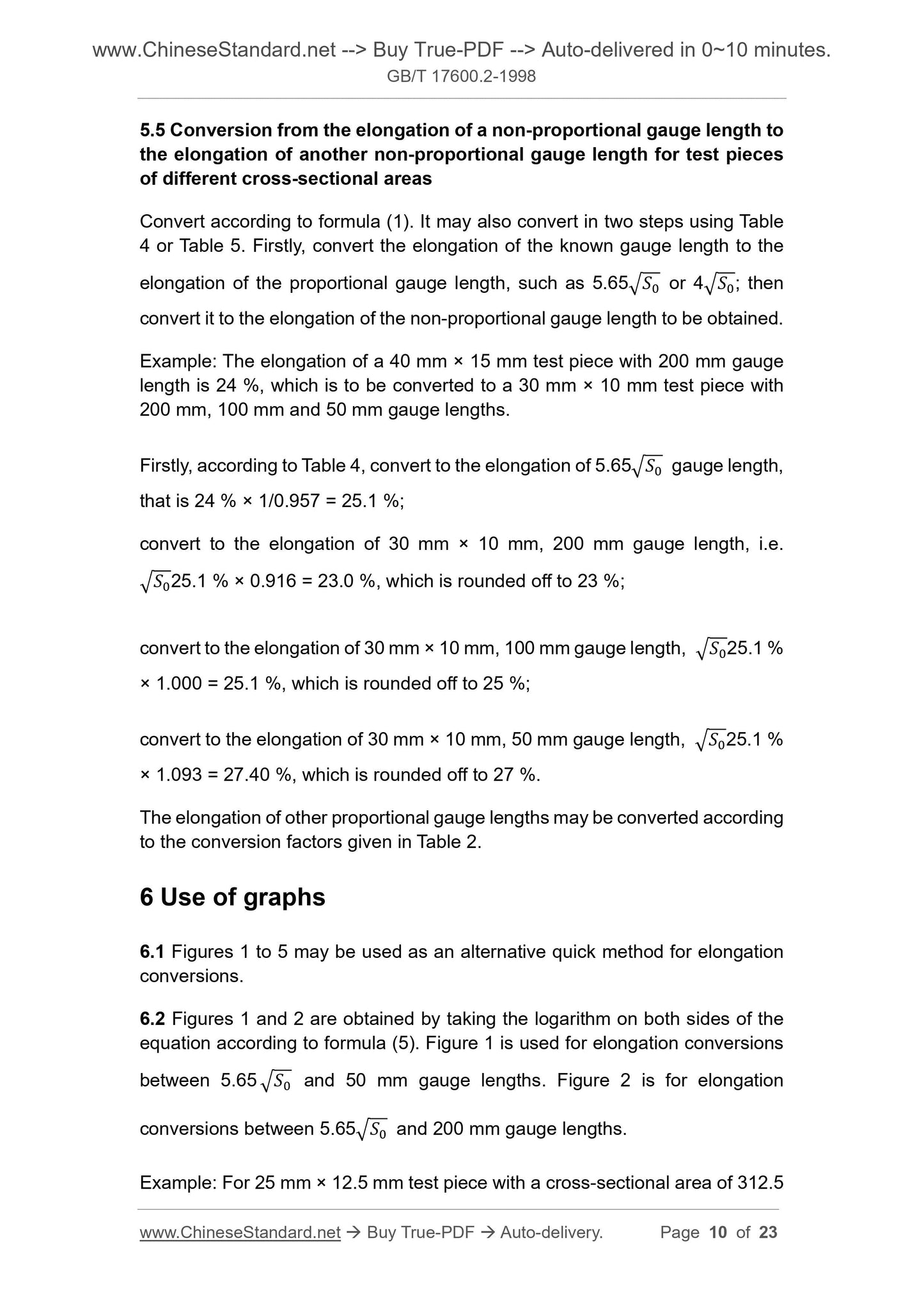

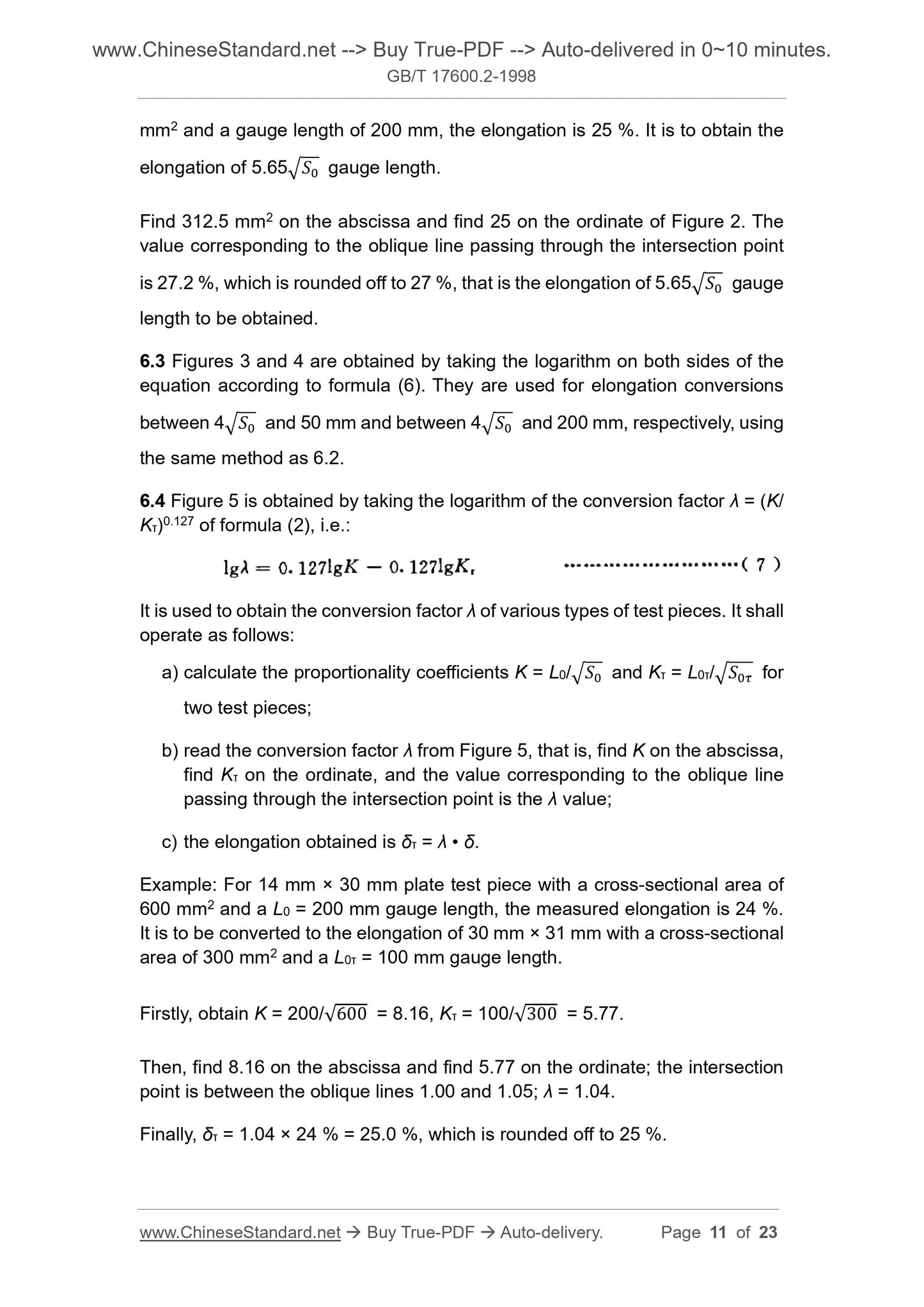

This Standard specifies a method of converting room temperature elongationsafter fracture obtained on various gauge lengths. It includes the conversion

formula and the conversion factor table of the elongation, as well as the graphs

for performing such conversions.

This Standard is applicable to the test piece of austenitic stainless steels in

solution treatment condition within the tensile strength range 450 to 750 MPa,

with an original gauge length not exceed 25ඥ𝑆, and a width to thickness ratio

not exceed 20.

This Standard is not applicable to cold rolled steels, quenched and tempered

steels and non-austenitic steels.

In the case of plate test piece under 3 mm thickness, the index n in formula (1)

of this Standard increases with decreasing thickness. The conversion value of

elongation shall be the subject of agreement between the customer and the

supplier.

The conversion method of this Standard is adopted internationally, and the

conversions are reliable within the scope of this Standard. However, because

of the various factors influencing the determination of elongations, whether to

use the conversions of this Standard shall be determined by the relevant

standards or agreements

In cases of dispute or arbitration, the elongation value shall be determined on

the gauge length stated in the relevant standards or agreements.

Basic Data

| Standard ID | GB/T 17600.2-1998 (GB/T17600.2-1998) |

| Description (Translated English) | Steel. Conversion of elongation values. Part 2: Austenitic steels |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | H22 |

| Classification of International Standard | 77.040.10 |

| Word Count Estimation | 18,124 |

| Date of Issue | 12/7/1998 |

| Date of Implementation | 7/1/1999 |

| Adopted Standard | ISO 2566-2-1984, MOD |

| Issuing agency(ies) | State Quality and Technical Supervision |

| Summary | This standard specifies the different gauge conversion method at room temperature between Elongation, including the conversion formula and the translation elongation factor for such conversion tables and graphs. |

Share