1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 16823.1-1997 English PDF (GB/T16823.1-1997)

GB/T 16823.1-1997 English PDF (GB/T16823.1-1997)

Regular price

$155.00

Regular price

Sale price

$155.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

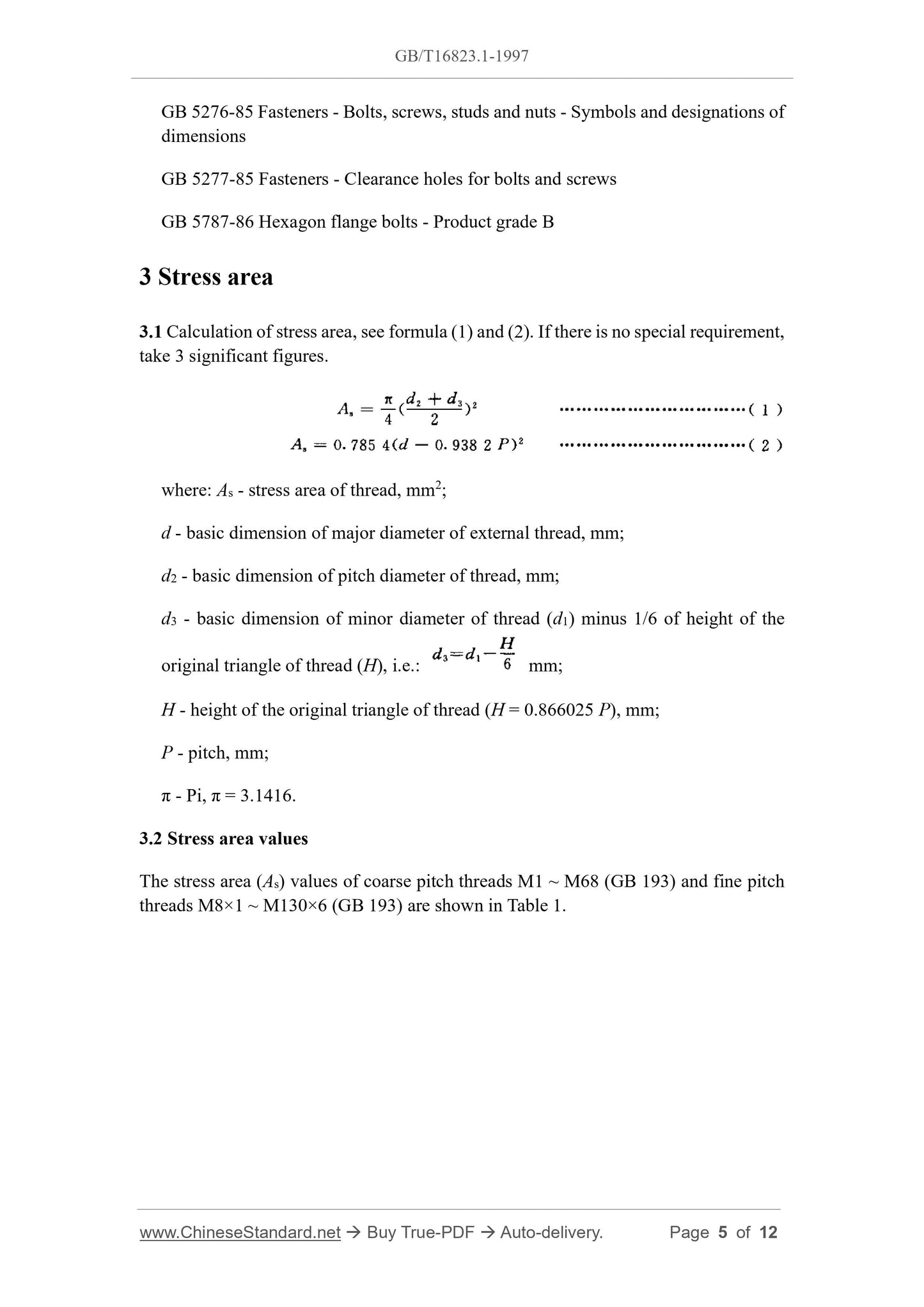

GB/T 16823.1-1997: Stress area and bearing area for theraded fasteners

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 16823.1-1997 (Self-service in 1-minute)

Newer / historical versions: GB/T 16823.1-1997

Preview True-PDF

Scope

This Standard specifies the stress area of threaded fasteners (hereinafter referred to asstress area) and the area of the load-bearing part of the bearing surface (hereinafter

referred to as bearing area).

The stress area applies to the stress calculation of external threads and also to the

calculation of the guaranteed load of internal threads. The thread dimensions and

tolerances shall comply with GB 193, GB 196 and GB 197.

Basic Data

| Standard ID | GB/T 16823.1-1997 (GB/T16823.1-1997) |

| Description (Translated English) | Stress area and bearing area for theraded fasteners |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | J13 |

| Classification of International Standard | 21.060.01 |

| Word Count Estimation | 11,187 |

| Date of Issue | 5/29/1997 |

| Date of Implementation | 12/1/1997 |

| Adopted Standard | JIS B1082-1987, MOD |

| Summary | This standard specifies the threaded fasteners stress area (hereinafter referred to as stress cross-sectional area) and bear the load bearing surface area of ??the part (hereinafter referred to as the bearing area). Sectional area of ??the stress applied to the external thread of the calculation of stress, but also to ensure that the calculation load of the thread. Its thread dimensions and tolerances shall comply with the GB 193, GB 196 and GB 197. |

Share