1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 16595-2019 English PDF (GB/T16595-2019)

GB/T 16595-2019 English PDF (GB/T16595-2019)

Regular price

$140.00

Regular price

Sale price

$140.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

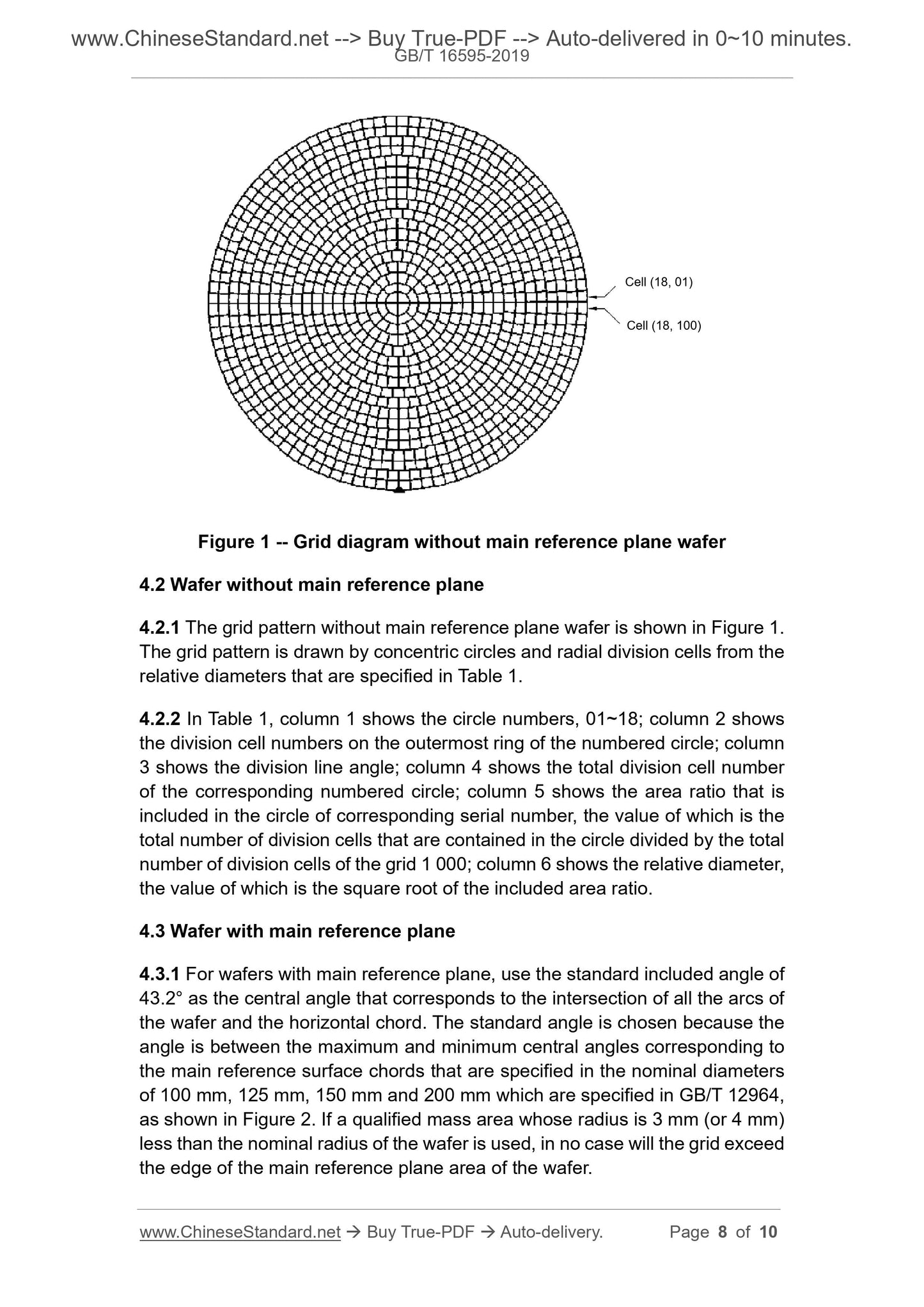

GB/T 16595-2019: Specification for a Universal Wafer Grid

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 16595-2019 (Self-service in 1-minute)

Newer / historical versions: GB/T 16595-2019

Preview True-PDF

Scope

This Standard specifies grid patterns that can be used to quantitatively describesurface defects on a circular semiconductor wafer.

This Standard applies to silicon wafers of which the nominal diameter is 100

mm ~ 200 mm; it also applies to other semiconductor material wafers

Basic Data

| Standard ID | GB/T 16595-2019 (GB/T16595-2019) |

| Description (Translated English) | Specification for a Universal Wafer Grid |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | H80 |

| Classification of International Standard | 29.045 |

| Word Count Estimation | 10,135 |

| Date of Issue | 2019-03-25 |

| Date of Implementation | 2020-02-01 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share