1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 14986.5-2018 English PDF (GB/T14986.5-2018)

GB/T 14986.5-2018 English PDF (GB/T14986.5-2018)

Regular price

$145.00

Regular price

Sale price

$145.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 14986.5-2018: Soft magnetic alloys - Part 5: Iron-aluminum alloys

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 14986.5-2018 (Self-service in 1-minute)

Newer / historical versions: GB/T 14986.5-2018

Preview True-PDF

Scope

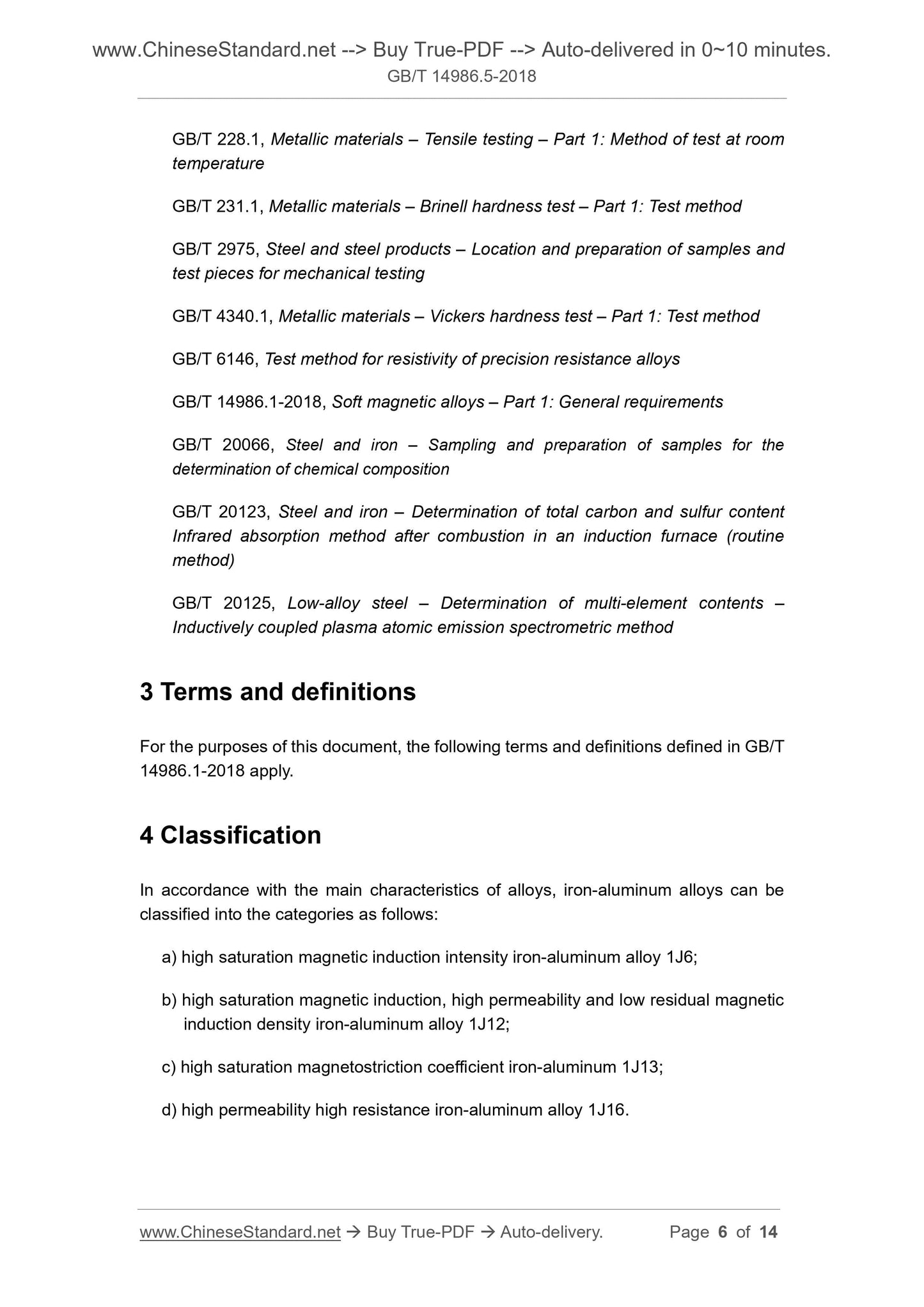

This Part of GB/T 14986 specifies the terms and definitions, classification, orderingcontent, dimensions, shape, technical requirements, inspection rules, test methods,

packaging, marking, quality certification, etc. of iron-aluminum soft magnetic alloys.

This Part applies to iron-aluminum soft magnetic cold-rolled strips, warm-rolled strips,

hot-rolled (forged) rods and polished or ground rods (hereinafter referred to as alloys).

Basic Data

| Standard ID | GB/T 14986.5-2018 (GB/T14986.5-2018) |

| Description (Translated English) | Soft magnetic alloys - Part 5: Iron-aluminum alloys |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | H58 |

| Classification of International Standard | 77.140.40 |

| Word Count Estimation | 9,954 |

| Date of Issue | 2018-05-14 |

| Date of Implementation | 2019-02-01 |

| Older Standard (superseded by this standard) | GB/T 14986-2008���� |

| Regulation (derived from) | National Standards Announcement No. 6 of 2018 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share