1

/

of

7

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 14644-2014 English PDF (GB/T14644-2014)

GB/T 14644-2014 English PDF (GB/T14644-2014)

Regular price

$85.00

Regular price

Sale price

$85.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

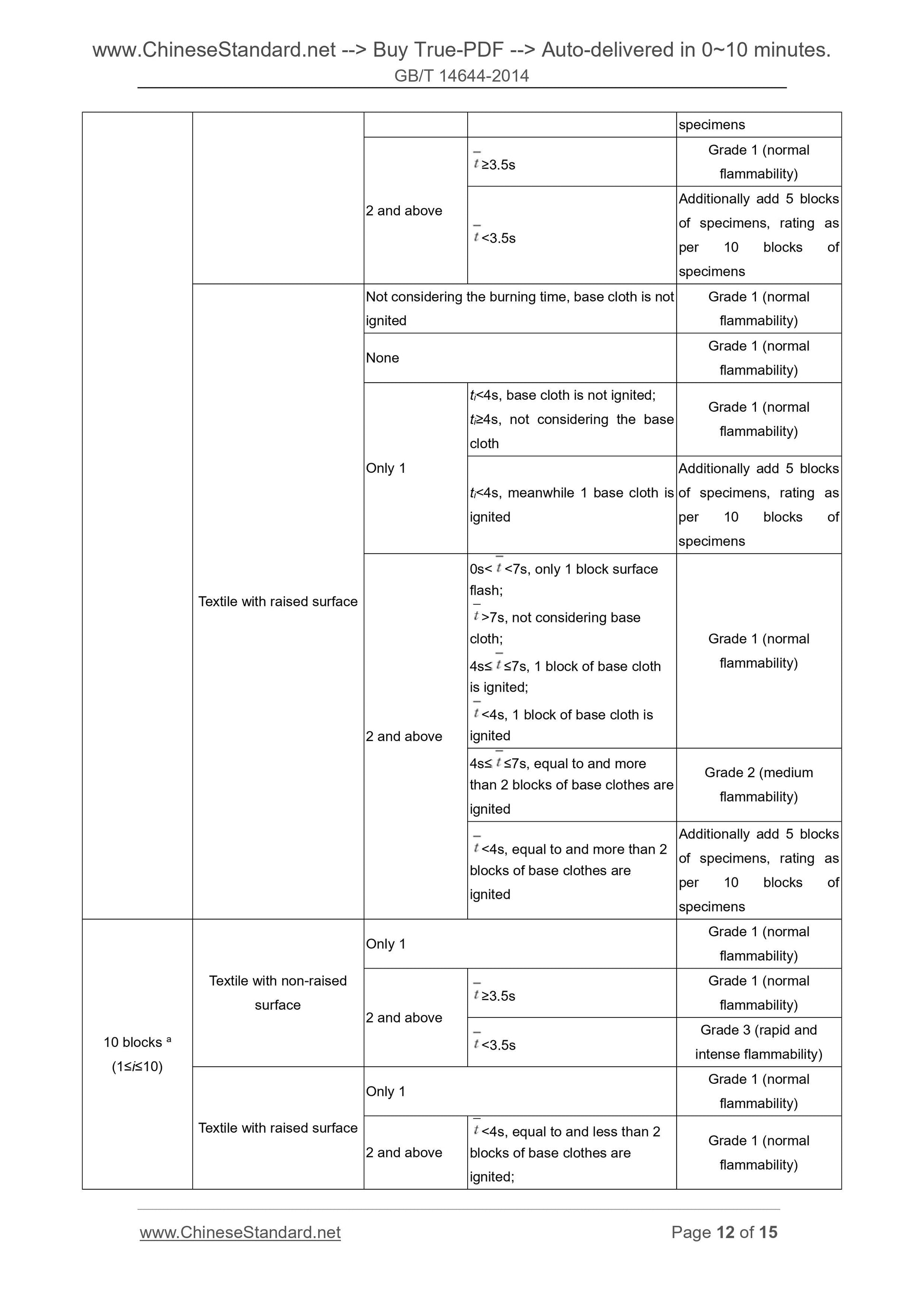

GB/T 14644-2014: Textiles - Burning Behaviour - Test Determination of Flame Spread Rate

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 14644-2014 (Self-service in 1-minute)

Newer / historical versions: GB/T 14644-2014

Preview True-PDF

Scope

This Standard specifies using 45° directional surface ignition to determine the testmethod and rating of the fabric combustibility.

This Standard is applicable to all types of fabrics and their products.

Basic Data

| Standard ID | GB/T 14644-2014 (GB/T14644-2014) |

| Description (Translated English) | Textiles - Burning Behaviour - Test Determination of Flame Spread Rate |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | W04 |

| Classification of International Standard | 59.080.30 |

| Word Count Estimation | 10,128 |

| Date of Implementation | 4/1/2015 |

| Older Standard (superseded by this standard) | GB/T 14644-1993 |

| Quoted Standard | GB/T 6836; GB/T 8629 |

| Regulation (derived from) | People's Republic of China Announcement of Newly Approved National Standards 2014 No. 22 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This Standard specifies the direction of the surface using 45 �� Test Method for ignition combustion properties of the fabric, as well as staged combustion performance. This Standard applies to all types of fabric and its products. |

Share