1

/

of

12

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 13448-2006 English PDF (GB/T13448-2006)

GB/T 13448-2006 English PDF (GB/T13448-2006)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

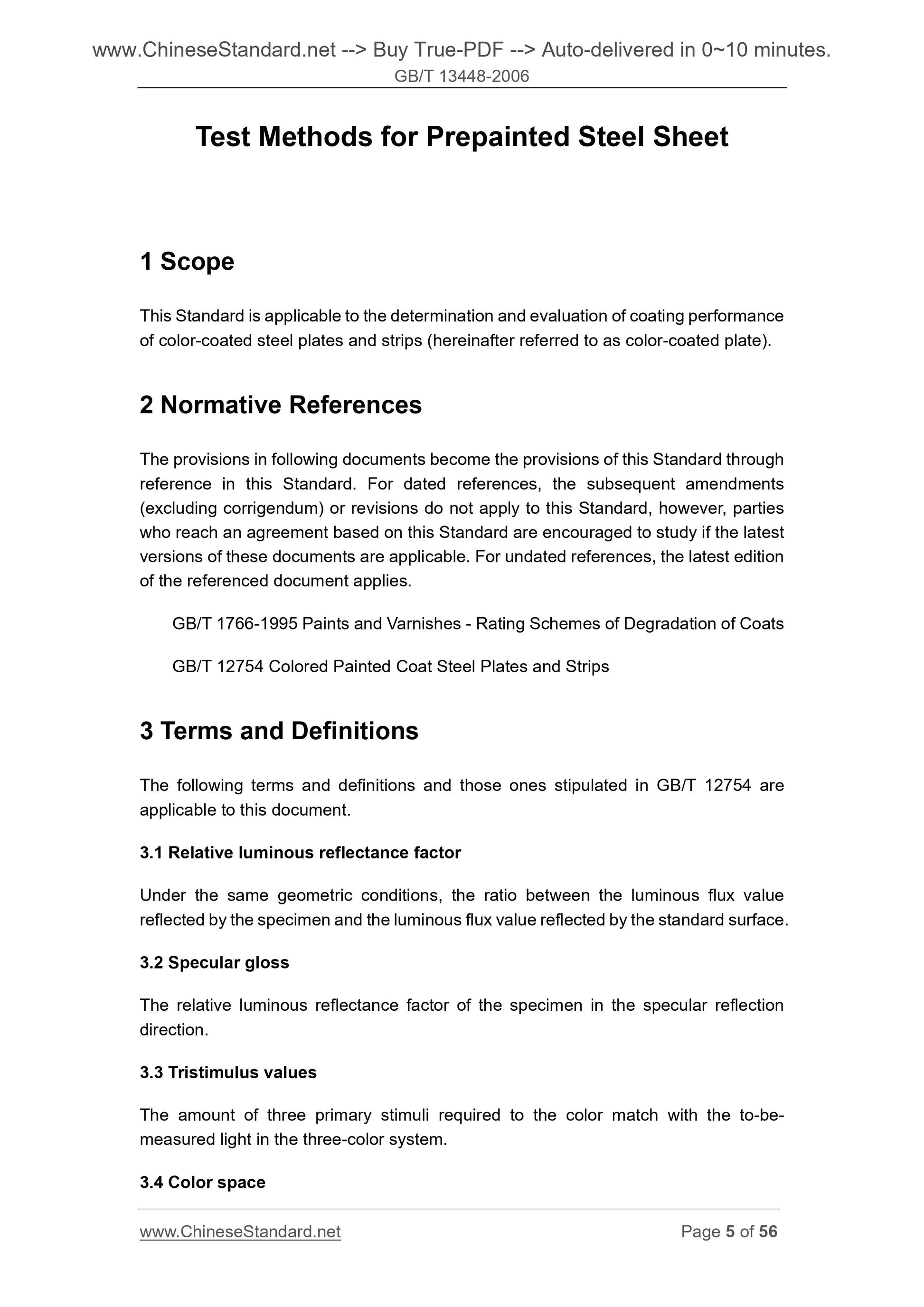

GB/T 13448-2006: Test methods for prepainted steel sheet

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 13448-2006 (Self-service in 1-minute)

Newer / historical versions: GB/T 13448-2006

Preview True-PDF

Scope

This Standard is applicable to the determination and evaluation of coating performanceof color-coated steel plates and strips (hereinafter referred to as color-coated plate).

Basic Data

| Standard ID | GB/T 13448-2006 (GB/T13448-2006) |

| Description (Translated English) | Test methods for prepainted steel sheet |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | H25 |

| Classification of International Standard | 77.060 |

| Word Count Estimation | 33,342 |

| Date of Issue | 2006-02-05 |

| Date of Implementation | 2006-08-01 |

| Older Standard (superseded by this standard) | GB/T 13448-1992 |

| Quoted Standard | GB/T 1766-1995; GB/T 12754 |

| Regulation (derived from) | Announcement of Newly Approved National Standards 2006 No. 2 (No. 89 overall) |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard applies to color coated steel sheet and strip (hereinafter referred to as color-coated) coating performance measurement and evaluation. |

Share