1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 13025.10-2012 English PDF (GB/T13025.10-2012)

GB/T 13025.10-2012 English PDF (GB/T13025.10-2012)

Regular price

$110.00

Regular price

Sale price

$110.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 13025.10-2012: General Test Method in Salt Industry - Determination of Ferrocyanide

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 13025.10-2012 (Self-service in 1-minute)

Newer / historical versions: GB/T 13025.10-2012

Preview True-PDF

Scope

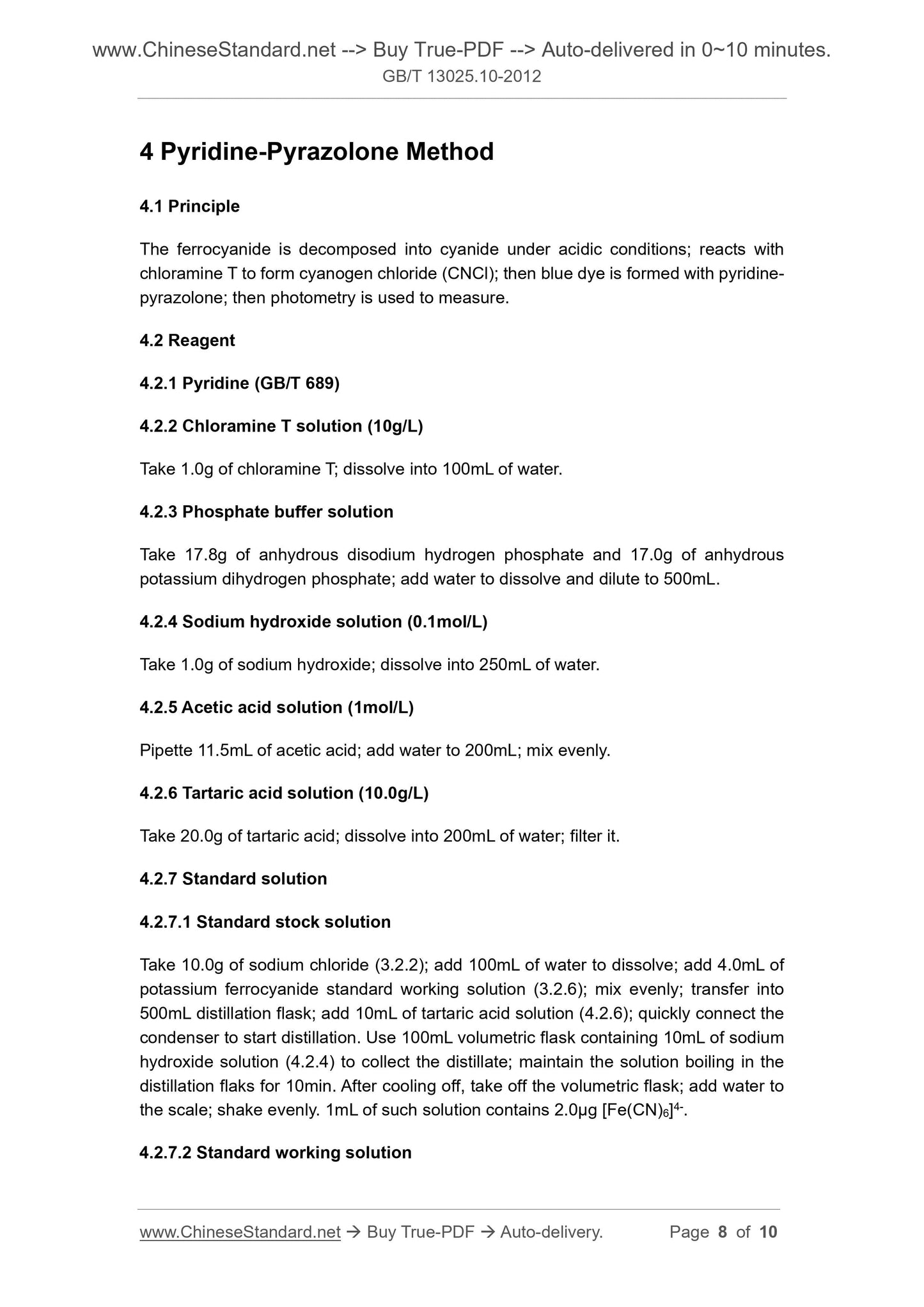

This Part of GB/T 13025 specifies the test method of determining the ferrocyanide inthe edible salt.

The ferrous sulfate method in this Part is applicable to the determination of samples

with a ferrocyanide content of 1mg/kg above; while the pyridine-pyrazolone method is

applicable to the determination of samples with a ferrocyanide content of 1mg/kg below.

Basic Data

| Standard ID | GB/T 13025.10-2012 (GB/T13025.10-2012) |

| Description (Translated English) | General Test Method in Salt Industry - Determination of Ferrocyanide |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | X35 |

| Classification of International Standard | 71.060.50 |

| Word Count Estimation | 7,752 |

| Older Standard (superseded by this standard) | GB/T 13025.10-2003 |

| Quoted Standard | GB/T 6682-2008 |

| Regulation (derived from) | National Standards Bulletin 2012 No. 13 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the ferrous cyanide salt in the test method. The law applies to the part of ferrous sulfate ferrous cyanide content of 1 mg/kg or more sample measured, pyridine pyrazolone law applies to ferrous cyanide content of 1 mg/kg the follo |

Share