1

/

of

9

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 10322.1-2014 English PDF (GB/T10322.1-2014)

GB/T 10322.1-2014 English PDF (GB/T10322.1-2014)

Regular price

$995.00

Regular price

Sale price

$995.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 10322.1-2014: Iron ores -- Sampling and sample preparation procedures

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 10322.1-2014 (Self-service in 1-minute)

Newer / historical versions: GB/T 10322.1-2014

Preview True-PDF

Scope

This Part of GB/T 10322 gives the mechanical sampling, manual sampling andpreparation of samples taken from a lot under transfer, and determines the chemical

composition, moisture content, size distribution and other physical and metallurgical

properties of the lot, except bulk density obtained using ISO 3852:2007 (Method 2). It

includes:

a) the underlying theory,

b) the basic principles for sampling and preparation of samples, and

c) the basic requirements for the design, installation and operation of sampling

systems.

The methods specified in this Part are applicable to both the loading and discharging

of a lot by means of belt conveyors and other ore-handling equipment to which a

mechanical sampler may be installed or where manual sampling may safely be

conducted.

The methods are applicable to all iron ores, whether natural or processed (e.g.,

concentrates and agglomerates, such as pellets or sinters).

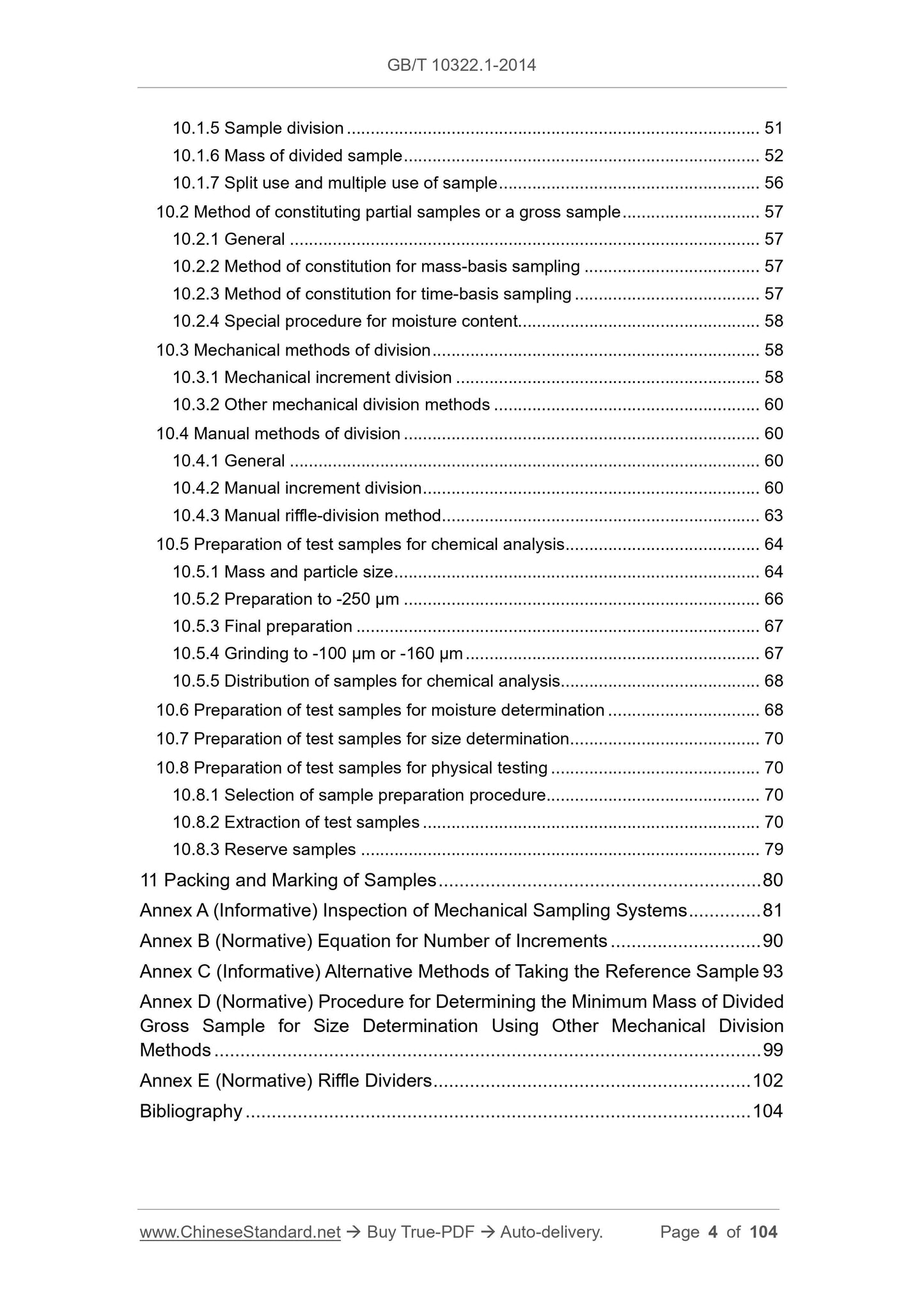

Basic Data

| Standard ID | GB/T 10322.1-2014 (GB/T10322.1-2014) |

| Description (Translated English) | Iron ores -- Sampling and sample preparation procedures |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | D31 |

| Classification of International Standard | 73.060.10 |

| Word Count Estimation | 72,752 |

| Date of Issue | 6/24/2014 |

| Date of Implementation | 4/1/2015 |

| Older Standard (superseded by this standard) | GB/T 10322.1-2000 |

| Quoted Standard | ISO 565; ISO 3084; ISO 3085-2002; ISO 3086; ISO 3087; ISO 3271; ISO 3310-1; ISO 3310-2; ISO 3852-2007; ISO 4695; ISO 4996-1; ISO 4696-2; ISO 4698; ISO 4700; ISO 4701; ISO 7215; ISO 7992; ISO 8371; ISO 11256; ISO 11257; ISO 11258; ISO 11323; ISO 13930 |

| Adopted Standard | ISO 3082-2009, IDT |

| Regulation (derived from) | National Standards Bulletin No. 14 of 2014 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the chemical composition, moisture content, particle size distribution, and physical and metallurgical properties of the delivery lot (except for the bulk density measured by ISO 3952-2007 method 2), from a delivery batch Manual sampling and sample preparation methods, including: a) basic theory; b) the basic principles of sampling and sample preparation; and c) the basic requirements for the design, installation and operation of the sampling system. The methods specified in this standard apply to the sampling of the delivery lot during the loading and unloading process for belt conveyors and other ore transport equipment. Belt conveyors and other ore transport equipment can be installed mechanical sampling machine, can also be safely on the equipment for manual sampling. These methods are suitable for all iron ore, whether natural or processed |

Share