1

/

of

8

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 10051.2-2010 English PDF (GB/T10051.2-2010)

GB/T 10051.2-2010 English PDF (GB/T10051.2-2010)

Regular price

$130.00

Regular price

Sale price

$130.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 10051.2-2010: Lifting hooks -- Part 2: Technical conditions for forged hooks

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 10051.2-2010 (Self-service in 1-minute)

Newer / historical versions: GB/T 10051.2-2010

Preview True-PDF

Scope

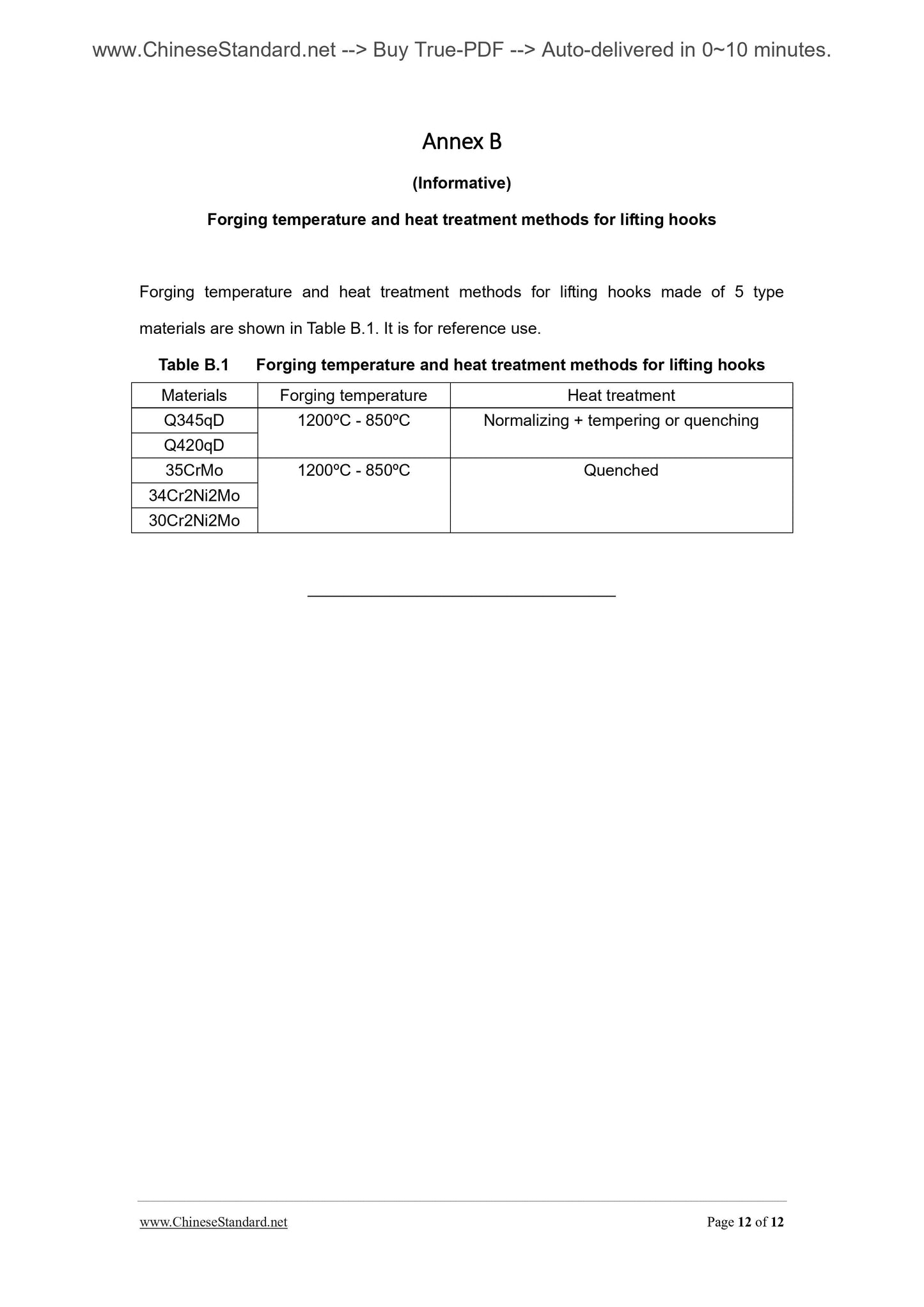

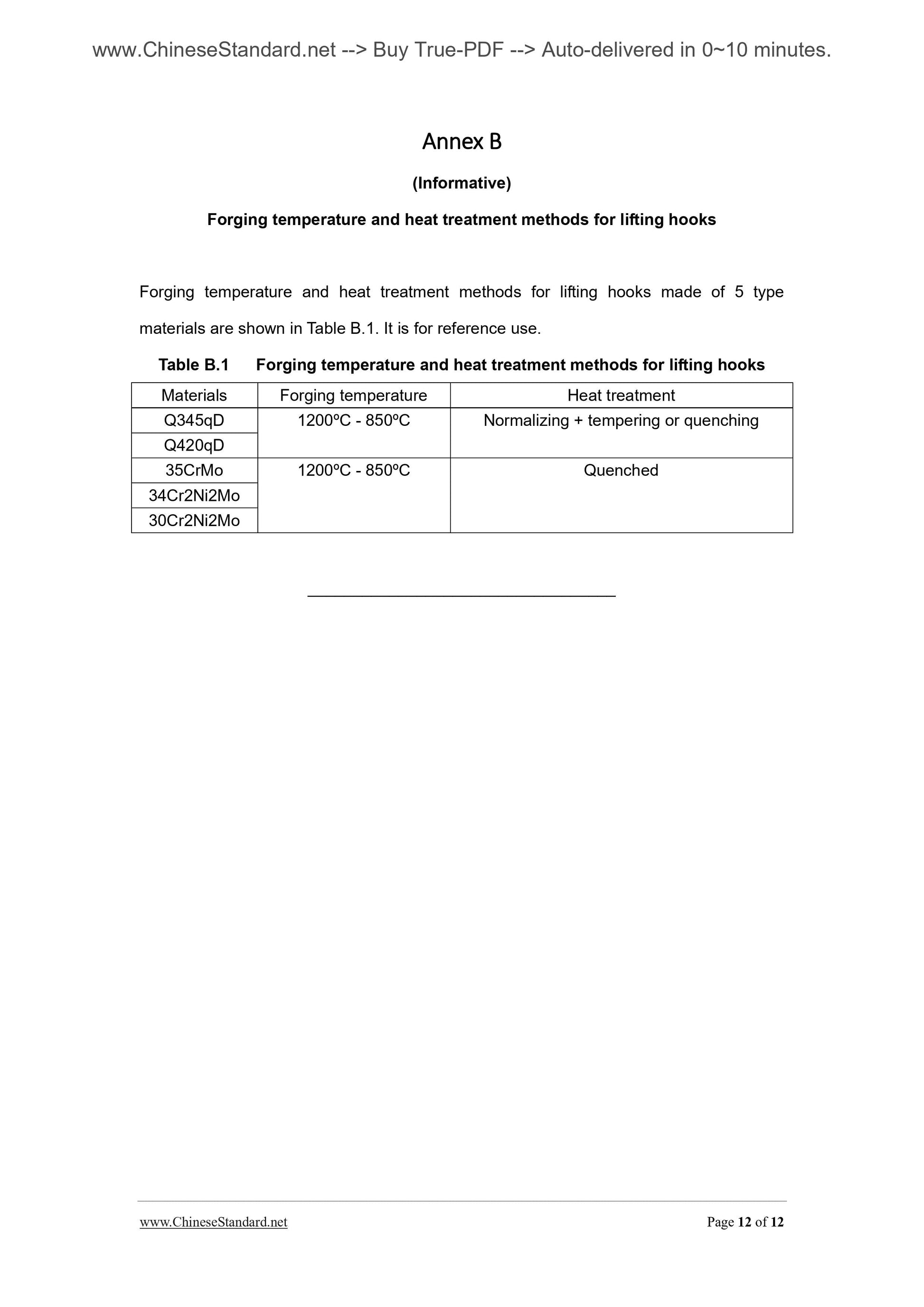

This Part of GB/T 10051 specifies technical requirements, test methods, inspection rules,marking, packaging, transportation and storage for forged hooks. This Part applies to

forged hooks used for lifting machinery specified in GB/T 10051.1 (hereinafter referred to

as hooks).

Basic Data

| Standard ID | GB/T 10051.2-2010 (GB/T10051.2-2010) |

| Description (Translated English) | Lifting hooks -- Part 2: Technical conditions for forged hooks |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | J80 |

| Classification of International Standard | 53.020.30 |

| Word Count Estimation | 9,917 |

| Date of Issue | 2011-01-10 |

| Date of Implementation | 2011-06-01 |

| Older Standard (superseded by this standard) | GB/T 10051.2-1988 |

| Quoted Standard | GB/T 197; GB/T 223; GB/T 228; GB/T 229; GB/T 1804; GB/T 2975; GB/T 10051.1-2010; GB/T 10051.4; GB/T 10051.5; GB/T 10051.6; GB/T 10051.7; GB/T 13384; GB/T 20066; JB/T 5000.15-2007 |

| Adopted Standard | DIN 15404-1-1989, MOD |

| Regulation (derived from) | National Standard Approval Announcement 2011 No.1 (Total No.166) |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the technical requirements for forging hook, test methods, inspection rules, signs, packaging, transport and storage. This section applies to GB/T 10051. 1 specified in lifting machinery forging hook (hereinafter referred to as the hook). |

Share