1

/

of

5

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 10006-1988 English PDF (GB/T10006-1988)

GB/T 10006-1988 English PDF (GB/T10006-1988)

Regular price

$120.00

Regular price

Sale price

$120.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 10006-1988: Plastics. Film and sheeting. Determination of the coefficients of friction

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 10006-1988 (Self-service in 1-minute)

Newer / historical versions: GB/T 10006-1988

Preview True-PDF

Scope

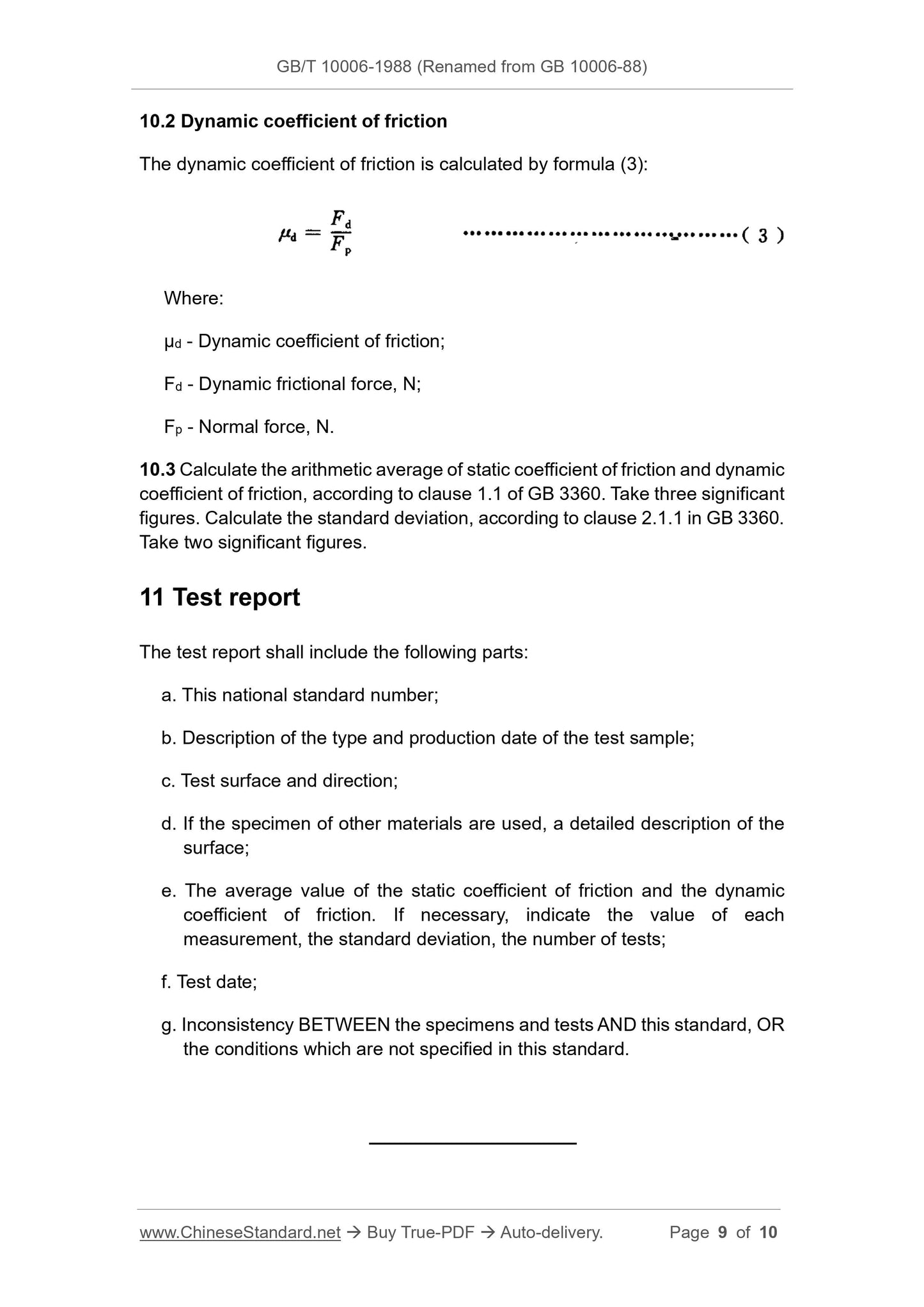

This standard specifies the methods for determining the static friction coefficientand dynamic friction coefficient, when plastic films and sheets slide on the

surface of themselves or other materials.

This standard is applicable to the following non-adhesive plastic films and

sheets, which have a thickness of below 0.2 mm.

Basic Data

| Standard ID | GB/T 10006-1988 (GB/T10006-1988) |

| Description (Translated English) | Plastics. Film and sheeting. Determination of the coefficients of friction |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | G33 |

| Classification of International Standard | 83.14 |

| Word Count Estimation | 4,432 |

| Date of Issue | 12/10/1988 |

| Date of Implementation | 7/1/1989 |

| Quoted Standard | GB 2918; GB/T 3360 |

| Adopted Standard | ISO 8295-1986, IDT |

| Summary | This standard specifies the plastic film and sheeting static and dynamic friction coefficient of determination of the coefficient of friction when sliding surface itself or other materials. This standard applies to the thickness of 0. 2mm or less non-sticky plastic film and sheeting. |

Share