1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB 50669-2011 English PDF

GB 50669-2011 English PDF

Regular price

$145.00

Regular price

Sale price

$145.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB 50669-2011: Code for Construction and Acceptance of Reinforced Concrete Silos

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB 50669-2011 (Self-service in 1-minute)

Newer / historical versions: GB 50669-2011

Preview True-PDF

Scope

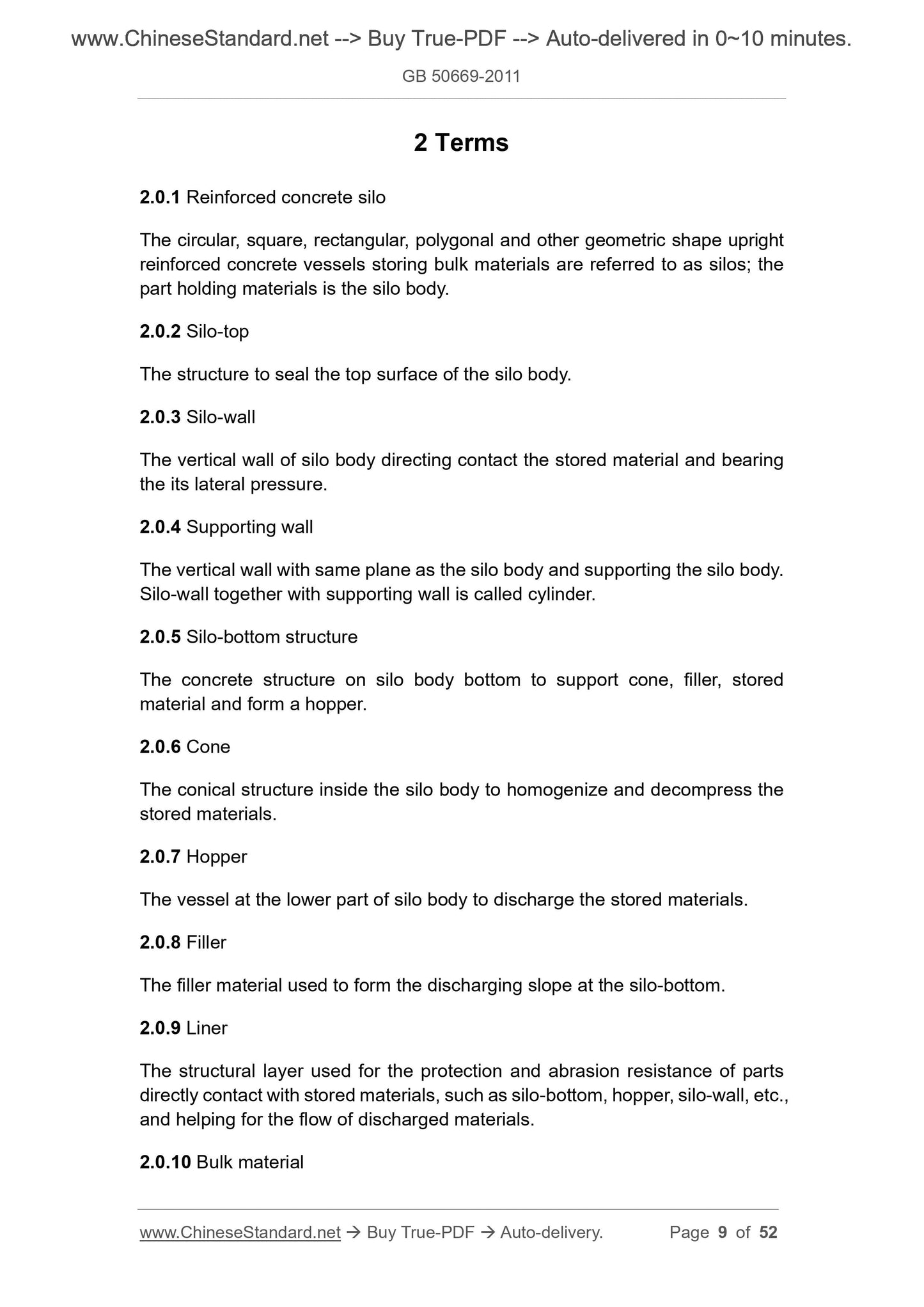

1.0.1 This code is formulated with a view to improving the construction level ofreinforced concrete silo works, regulating the quality acceptance of reinforced

concrete silo works and achieving advanced technology, reliable quality, safety,

usability, economy and rationality.

1.0.2 This code is applicable to the construction and quality acceptance of

circular or polygonal cast-in-place reinforced concrete silos storing bulk

materials and compressed air mixing silo of mixed powders.

1.0.3 The requirements for construction quality acceptance in the contract

agreement document and engineering technical document adopted for the

construction of reinforced concrete silo works shall not be less than the

requirements of this code.

1.0.4 New technologies, new processes, new equipment and new materials

shall be popularized in the construction of reinforced concrete silo works.

1.0.5 The construction of reinforced concrete silo works shall comply with the

management provisions of relevant OHS and environmental protection.

1.0.6 This code shall be used together with the current national standard

“Unified Standard for Constructional Quality Acceptance of Building

Engineering” GB 50300.

1.0.7 The construction and quality acceptance of reinforced concrete silo works

shall not only comply with this code but also comply with those in the relevant

current national standards.

Basic Data

| Standard ID | GB 50669-2011 (GB50669-2011) |

| Description (Translated English) | Code for Construction and Acceptance of Reinforced Concrete Silos |

| Sector / Industry | National Standard |

| Classification of Chinese Standard | P34 |

| Classification of International Standard | 91.040.20 |

| Word Count Estimation | 99,992 |

| Date of Issue | 2011-02-18 |

| Date of Implementation | 2011-05-01 |

| Quoted Standard | GB 50017; GB 50113; GB 50202; GB 50204; GB 50205; GB 50300; JGJ 8; JGJ 33; JGJ 46; JGJ 59; JGJ 81; JGJ 79; JGJ 104; JGJ 106 |

| Regulation (derived from) | Bulletin of the Ministry of Housing and Urban No. 943 |

| Issuing agency(ies) | Ministry of Housing and Urban-Rural Development of the People's Republic of China; General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China |

| Summary | This Chinese standard applies to the storage of bulk materials, and the planar circular or polygonal shape situ reinforced concrete silos, compressed air mixed powder and mix thoroughly warehouse construction and quality acceptance. |

Share