1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB 50666-2011 English PDF

GB 50666-2011 English PDF

Regular price

$145.00

Regular price

Sale price

$145.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

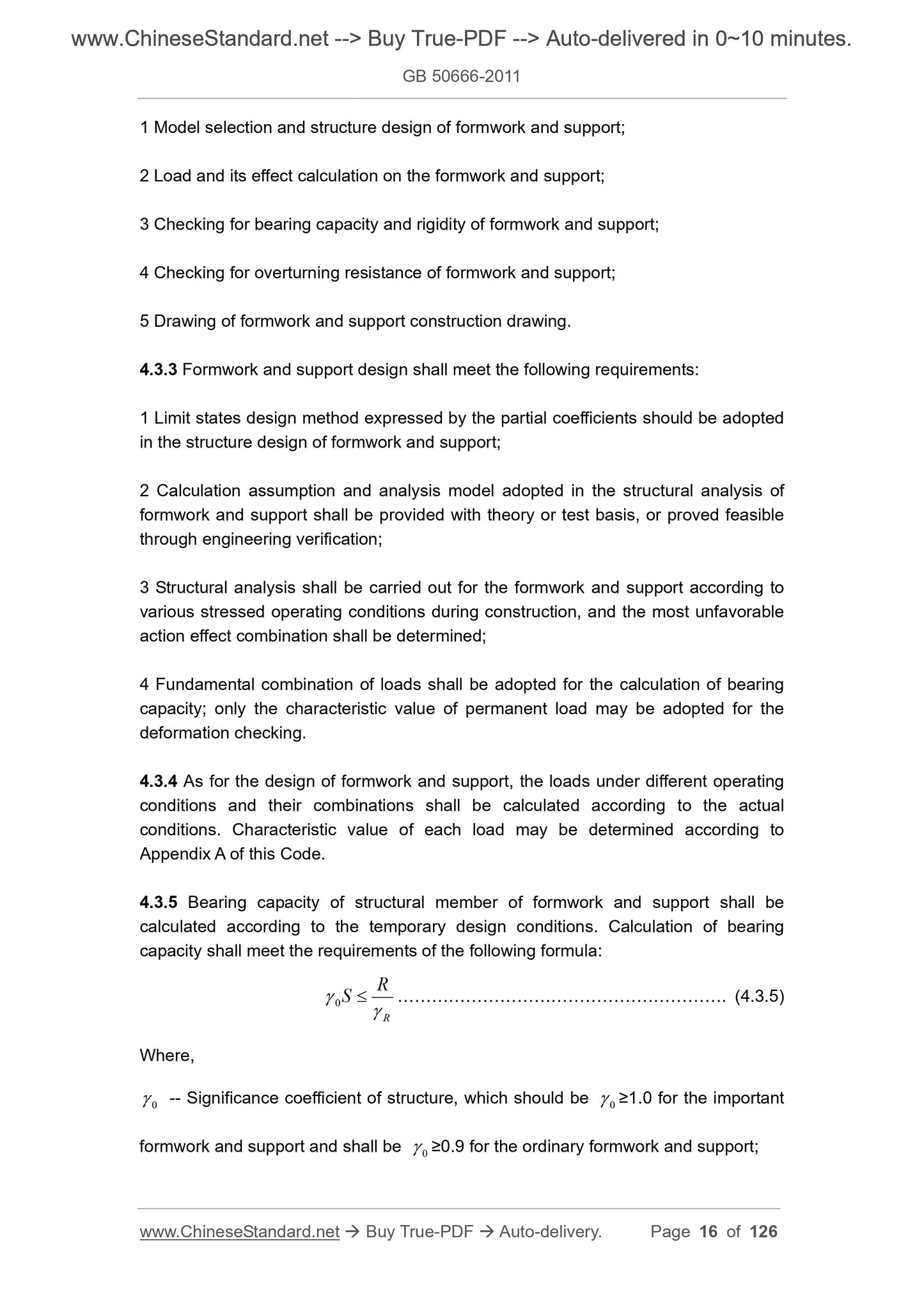

GB 50666-2011: Code for construction of concrete structures

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB 50666-2011 (Self-service in 1-minute)

Newer / historical versions: GB 50666-2011

Preview True-PDF

Scope

1.0.1 This Code is formulated with a view to implementing the national technical andeconomic policies, ensuring the engineering quality, and realizing advanced

technology, reasonable process, resources conservation and environmental

protection during the construction of concrete structures.

1.0.2 This Code is applicable to the construction of concrete structures in building

engineering, not to the construction of lightweight aggregate concrete and special

concrete.

1.0.3 This Code contains the basic requirements for the construction of concrete

structures. When there are special requirements for the construction stated in the

design documents, the construction shall also be implemented in accordance with the

design documents.

1.0.4 Construction of concrete structures shall not only meet the requirements of this

Code but also comply with those in the current relevant standards of the nation.

Basic Data

| Standard ID | GB 50666-2011 (GB50666-2011) |

| Description (Translated English) | Code for construction of concrete structures |

| Sector / Industry | National Standard |

| Classification of Chinese Standard | P25 |

| Classification of International Standard | 91.080.40 |

| Word Count Estimation | 221,250 |

| Date of Issue | 2011-07-29 |

| Date of Implementation | 2012-08-01 |

| Quoted Standard | GB 50007; GB 50009; GB 50010; GB/T 50080; GB/T 50081; GB/T 50107; GB 50119; GB 50204; GB/T 50476; GB/T 9142; GB 10171; GB 12523; GB/T 14370; GB 14902; GB/T 25182; JGJ 18; JGJ 55; JGJ 63; JGJ 85; JGJ/T 104; JGJ 107; JGJ 128; JGJ 130; JGJ 206; JGJ 256 |

| Regulation (derived from) | Bulletin of the Ministry of Housing and Urban No. 1110 |

| Issuing agency(ies) | Ministry of Housing and Urban-Rural Development of the People's Republic of China; General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China |

| Summary | This Chinese standard applies to the construction of concrete structures, does not apply to special lightweight aggregate concrete and concrete construction. |

Share