1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice In 1 second!

GB 50516-2010 English PDF

GB 50516-2010 English PDF

Regular price

$395.00

Regular price

Sale price

$395.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

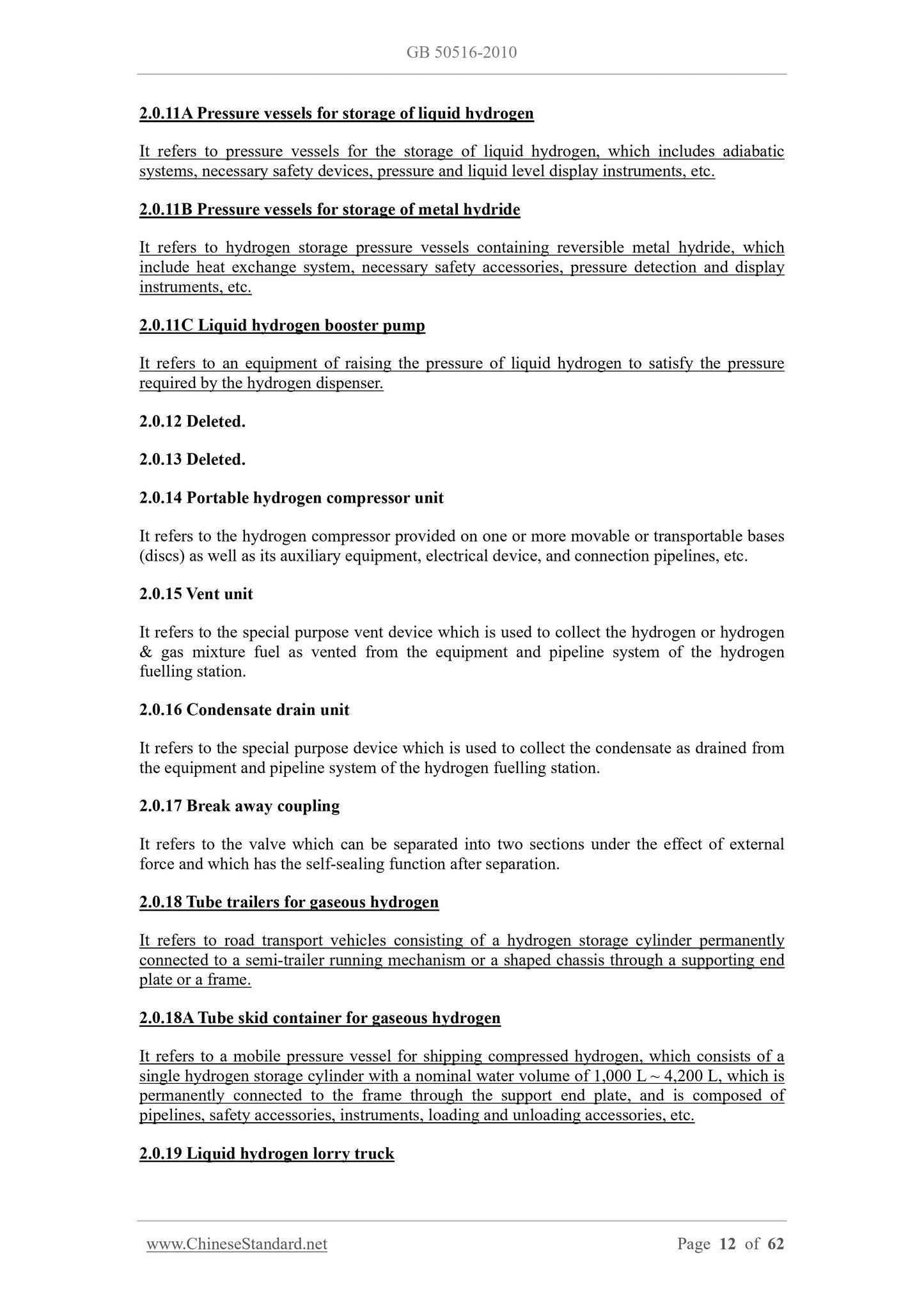

GB 50516-2010: [2021 Version] Technical code for hydrogen fuelling station

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB 50516-2010 (Self-service in 1-minute)

Newer / historical versions: GB 50516-2010

Preview True-PDF

Basic Data

| Standard ID | GB 50516-2010 (GB50516-2010) |

| Description (Translated English) | [2021 Version] Technical code for hydrogen fuelling station |

| Sector / Industry | National Standard |

| Classification of Chinese Standard | P33 |

| Word Count Estimation | 111,110 |

| Date of Issue | 2010-05-31 |

| Date of Implementation | 2010-12-01 |

| Quoted Standard | GB 50016; GB 50028; GB 50029; GB 50041; GB 50052; GB 50057; GB 50058; GB 50140; GB 50156; GB 50168; GB 50169; GB 50171; GB 50177; GB 50235; GB 50236; GB 50242; GB 50257; GB 50275; GB 50303; GB 3634; GB 4962; GB 5310; GB/T 7445; GB/T 8163; GB/T 14976; GB 16912; GB/T 19773; GB/T 19774; JB/T 4730; JB 4732; SH/T 3521; ANSI/ASME B31.3; ASTM A269 |

| Regulation (derived from) | Bulletin of the Ministry of Housing and Urban No. 642 |

| Issuing agency(ies) | Ministry of Housing and Urban-Rural Development of the People's Republic of China; General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China |

| Summary | This Chinese standard applies to the following new construction, renovation, expansion of hydrogen refueling station design, construction, construction: 1. Hydrogen refueling station, 2. Hydrogen refueling co Build 3. Hydrogenation aerated co Build, |

Share