1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB 50273-2022 English PDF

GB 50273-2022 English PDF

Regular price

$1,145.00

Regular price

Sale price

$1,145.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB 50273-2022: Standard for construction and acceptance of boiler installation engineering

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB 50273-2022 (Self-service in 1-minute)

Newer / historical versions: GB 50273-2022

Preview True-PDF

Scope

1.0.1 This Standard is formulated to improve the construction level of boiler installationengineering, promote technological progress, ensure project quality and safety, and

improve economic benefits.

1.0.2 This Standard applies to the construction and acceptance of fixed steam boilers

with a rated working pressure less than or equal to 3.82 MPa for industrial, civil and

district heating, fixed hot water boilers with a rated water outlet pressure greater than

0.1 MPa, and organic heat carrier furnace installation engineering. It is not applicable

to the construction and acceptance of cast iron boilers, boilers for transportation vehicle

and ship, nuclear power boilers, and power station boilers installation engineering.

1.0.3 Boilers whose engineering acceptance procedures have not been completed

are strictly prohibited from putting into use.

1.0.4 Before and during the installation of boilers, if any quality problems are

found in the pressure-bearing parts that affect safe use, the installation must be

stopped and it must be reported to the construction unit.

1.0.5 In addition to complying with this Standard, the construction and acceptance of

boiler installation engineering shall also comply with the provisions of relevant national

standards in force.

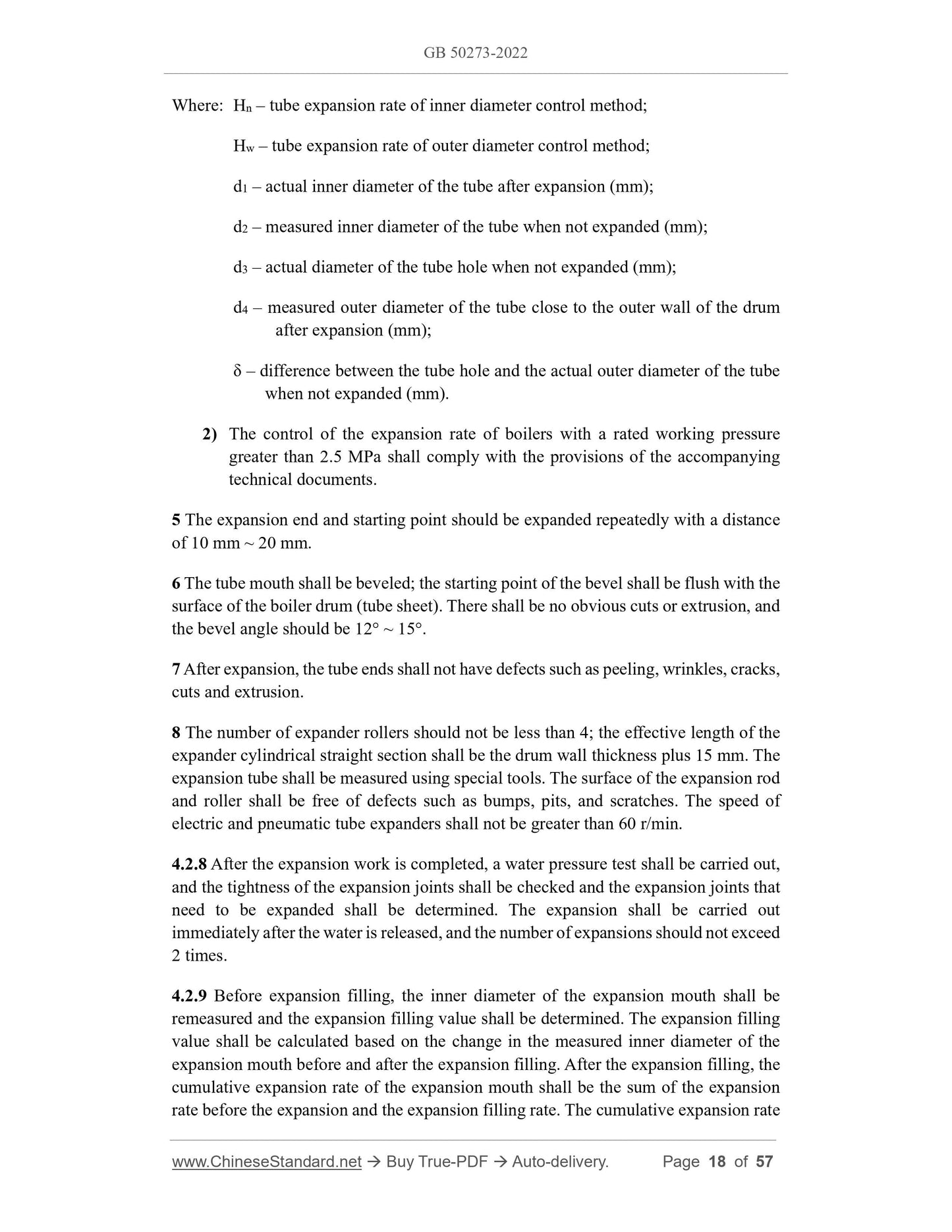

Where: Hn – tube expansion rate of inner diameter control method;

Hw – tube expansion rate of outer diameter control method;

d1 – actual inner diameter of the tube after expansion (mm);

d2 – measured inner diameter of the tube when not expanded (mm);

d3 – actual diameter of the tube hole when not expanded (mm);

d4 – measured outer diameter of the tube close to the outer wall of the drum

after expansion (mm);

δ – difference between the tube hole and the actual outer diameter of the tube

when not expanded (mm).

2) The control of the expansion rate of boilers with a rated working pressure

greater than 2.5 MPa shall comply with the provisions of the accompanying

technical documents.

5 The expansion end and starting point should be expanded repeatedly with a distance

of 10 mm ~ 20 mm.

6 The tube mouth shall be beveled; the starting point of the bevel shall be flush with the

surface of the boiler drum (tube sheet). There shall be no obvious cuts or extrusion, and

the bevel angle should be 12° ~ 15°.

7 After expansion, the tube ends shall not have defects such as peeling, wrinkles, cracks,

cuts and extrusion.

8 The number of expander rollers should not be less than 4; the effective length of the

expander cylindrical straight section shall be the drum wall thickness plus 15 mm. The

expansion tube shall be measured using special tools. The surface of the expansion rod

and roller shall be free of defects such as bumps, pits, and scratches. The speed of

electric and pneumatic tube expanders shall not be greater than 60 r/min.

4.2.8 After the expansion work is completed, a water pressure test shall be carried out,

and the tightness of the expansion joints shall be checked and the expansion joints that

need to be expanded shall be determined. The expansion shall be carried out

immediately after the water is released, and the number of expansions should not exceed

2 times.

4.2.9 Before expansion filling, the inner diameter of the expansion mouth shall be

remeasured and the expansion filling value shall be determined. The expansion filling

value shall be calculated based on the change in the measured inner diameter of the

expansion mouth before and after the expansion filling. After the expansion filling, the

cumulative expansion rate of the expansion mouth shall be the sum of the expansion

rate before the expansion and the expansion filling rate. The cumulative expansion rate

3 The quality of the radiographic testing of the welds of the butt joints of the tubes on

heated side of the organic heat carrier furnace shall not be lower than Grade II, and the

quality of the ultrasonic testing shall not be lower than Grade I.

4.3.12 When adopting radiographic testing or ultrasonic testing, the number of non-

destructive tests shall comply with the following provisions:

1 When the rated working pressure of the steam boiler is equal to 3.82 MPa and the

nominal outer diameter is less than or equal to 159 mm, the number of non-destructive

tests shall not be less than 25% of the number of welded joints; when the rated working

pressure of the steam boiler is greater than 0.8 MPa and less than 3.82 MPa, and the

nominal outer diameter is less than or equal to 159 mm, the number of radiographic

tests shall not be less than 10% of the number of welded joints. When the rated working

pressure of the steam boiler is greater than 0.8 MPa, the nominal outer diameter is

greater than 159 mm or the nominal wall thickness is greater than or equal to 20 mm,

the welded joints shall be subjected to 100% non-destructive testing. When the rated

working pressure of the steam boiler is less than or equal to 0.8 MPa, non-destructive

testing is not required.

2 When the rated outlet water temperature of the hot water boiler is greater than or equal

to 120 ℃ and the nominal outer diameter is less than or equal to 159 mm, the number

of radiographic testing shall not be less than 10% of the total number of circumferential

seams; when the nominal outer diameter is greater than 159 mm or the wall thickness

is greater than or equal to 20 mm, each weld shall be 100% non-destructively inspected;

when the rated outlet water temperature of the hot water boiler is less than 120 ℃, non-

destructive testing is not required.

3 For the butt joints of the pressurized organic heat carrier furnace with an outer

diameter greater than or equal to 159 mm, 20% of the number of joints shall be

subjected to radiographic testing; for the butt joints of the tubes with an outer diameter

less than 159 mm, 10% of the number of joints shall be subjected to radiographic testing;

for the condensate tank, expansion tank and storage tank, 20% of each weld shall be

subjected to radiographic testing.

4 For welding joints with wall thickness less than 20 mm, the radiographic testing

method shall be used; for welding joints with wall thickness greater than or equal to 20

mm, the ultrasonic testing method can be used. The ultrasonic detector should be a

digital recordable instrument. When an analog ultrasonic detector is used, an additional

20% local X-ray detection shall be performed.

5 When the result of non-destructive testing is unqualified, in addition to repairing the

unqualified welds, the same type of welded joints welded by the welder on the same

day shall be re-inspected, and the number of re-inspections shall be twice the number

of random inspections. If there are still unqualified results after re-inspection, all

welding joints welded by the welder on that day shall be inspected.

4) When the rated thermal power of the gas phase organic heat carrier boiler is

greater than 0.7 MW or the rated thermal power of the liquid phase organic heat

carrier boiler is greater than 4.2 MW, the allowable pressure drop shall be less

than or equal to 0.10 MPa;

5) When the working pressure of the steam boiler is less than or equal to 0.8 MPa,

the rated outlet water temperature of the hot water boiler is less than 120 ℃, the

rated thermal power of the gas-phase organic heat carrier boiler is less than or

equal to 0.7 MW, and the rated thermal power of the liquid-phase organic heat

carrier boiler is less than or equal to 4.2 MW, the allowable pressure drop shall

be less than or equal to 0.05 MPa.

6 The test pressure shall be reduced to the rated working pressure for inspection after

the holding time. The pressure shall remain unchanged during the inspection. The water

pressure test is qualified when the inspection meets the following requirements:

1) There shall be no water droplets or mist on the metal wall and welds of the boiler

pressure components, and no water droplets shall drip from the expansion joints;

2) There shall be no visible residual deformation after the water pressure test.

5.0.6 If the boiler fails the water pressure test, it shall be repaired. The water pressure

test shall be repeated after repair.

5.0.7 After the boiler water pressure test, all water in the boiler shall be drained in time.

When the water in the vertical superheater cannot be drained, anti-freeze measures shall

be taken during the freezing period.

5.0.8 After the installation of the organic heat carrier furnace, a hydraulic test shall be

carried out at 1.5 times the rated working pressure. When the test medium is an organic

heat carrier, an air tightness test shall be carried out before the hydraulic test. When

water is used as the test medium, the water in the equipment shall be drained after the

water pressure test is completed, and the interior shall be blown dry with compressed

air. The pressure test requirements shall comply with the relevant provisions of

Subclause 5.0.5 of this Standard.

5.0.9 The gas phase furnace air tightness test of organic heat carrier furnace shall

comply with the following provisions:

1 During the air tightness test, safety accessories shall be fully installed;

2 The ambient temperature of the air tightness test shall not be lower than 5 ℃. When

the ambient temperature is lower than 5 ℃, anti-freezing measures shall be taken;

3 The gas used for air tightness test shall be dry, clean air, nitrogen or other inert gas,

and the temperature of the test gas shall not be lower than 5 °C;

Basic Data

| Standard ID | GB 50273-2022 (GB50273-2022) |

| Description (Translated English) | Standard for construction and acceptance of boiler installation engineering |

| Sector / Industry | National Standard |

| Classification of Chinese Standard | P93 |

| Word Count Estimation | 97,973 |

| Date of Issue | 2022-01-05 |

| Date of Implementation | 2022-05-01 |

| Issuing agency(ies) | Ministry of Housing and Urban-Rural Development of the People's Republic of China; State Administration for Market Regulation |

| Summary | This standard is applicable to the construction and acceptance of fixed steam boilers with rated working pressure less than or equal to 3.82MPa, fixed hot water boilers with rated water outlet pressure greater than 0.1MPa and organic heat carrier furnace installation projects for industrial, civil and district heating. It is not applicable to the construction and acceptance of cast iron boilers, transportation vehicle and marine boilers, nuclear energy boilers, and power plant boiler installation projects. |

Share