1

/

of

11

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB 5009.259-2023 English PDF

GB 5009.259-2023 English PDF

Regular price

$260.00

Regular price

Sale price

$260.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB 5009.259-2023: National food safety standard - Determination of biotin in foods

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB 5009.259-2023 (Self-service in 1-minute)

Newer / historical versions: GB 5009.259-2023

Preview True-PDF

Scope

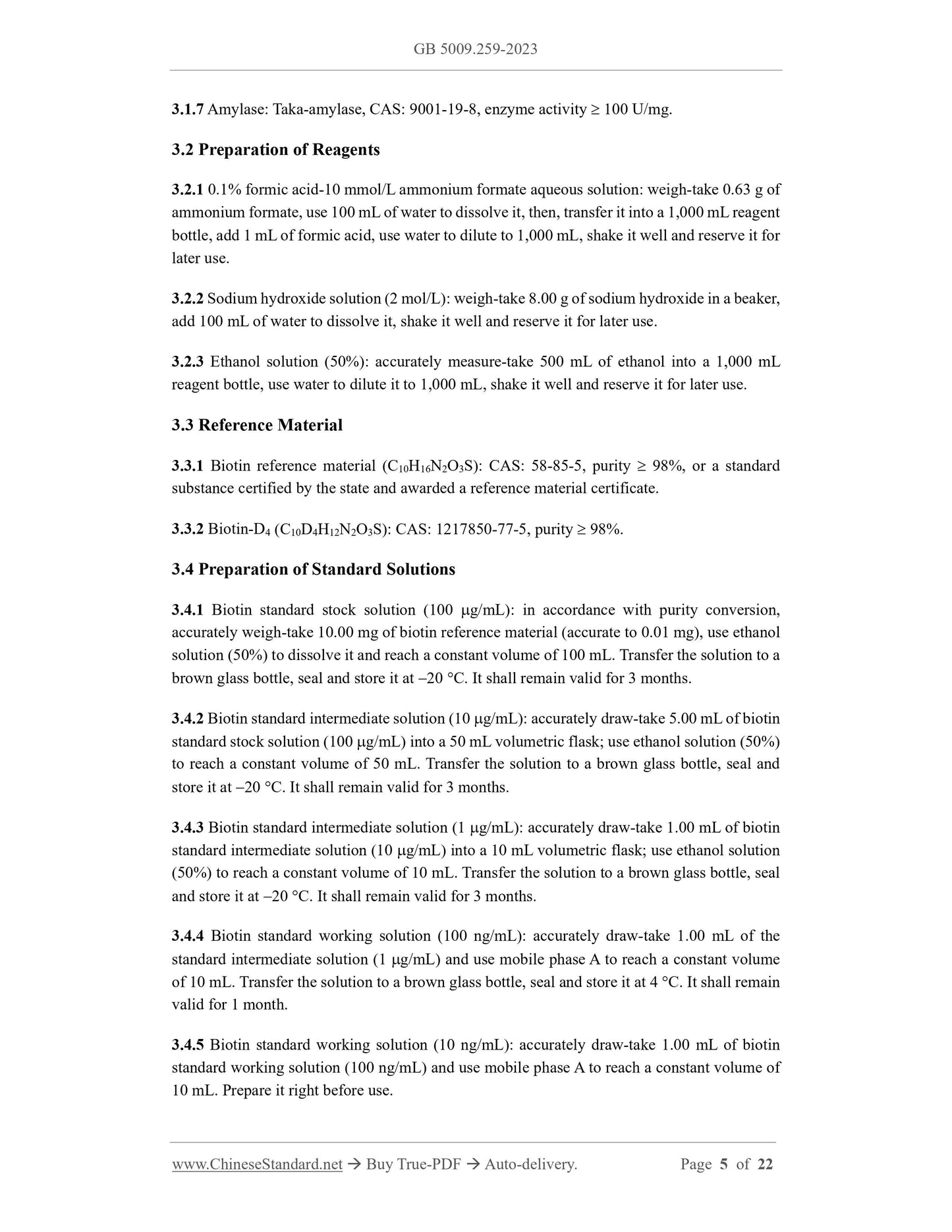

This Standard specifies the methods for the determination of biotin in foods.Method 1 - liquid chromatography - tandem mass spectrometry is applicable to the

determination of biotin in prepared milk powder and special dietary foods.

Method 2 - microbiological method is applicable to the determination of biotin in foods.

Method I - Liquid Chromatography - Tandem Mass

Spectrometry

Basic Data

| Standard ID | GB 5009.259-2023 (GB5009.259-2023) |

| Description (Translated English) | National food safety standard - Determination of sialic acid in foods |

| Sector / Industry | National Standard |

| Classification of Chinese Standard | X09 |

| Word Count Estimation | 15,196 |

| Date of Issue | 2023-09-06 |

| Date of Implementation | 2024-03-06 |

| Issuing agency(ies) | National Health Commission of the People's Republic of China, State Administration for Market Regulation |

| Summary | This standard specifies the determination method of sialic acid in food. The first method of this standard, liquid chromatography-ultraviolet detection, is applicable to the determination of bound sialic acid in bird's nests and its products. The second method, liquid chromatography-fluorescence detection, and the third method, liquid chromatography-mass spectrometry/mass spectrometry, are applicable to Determination of sialic acid in liquid milk, milk powder, cakes and beverages. |

Share