1

/

of

10

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB 5009.210-2016 English PDF

GB 5009.210-2016 English PDF

Regular price

$135.00

Regular price

Sale price

$135.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

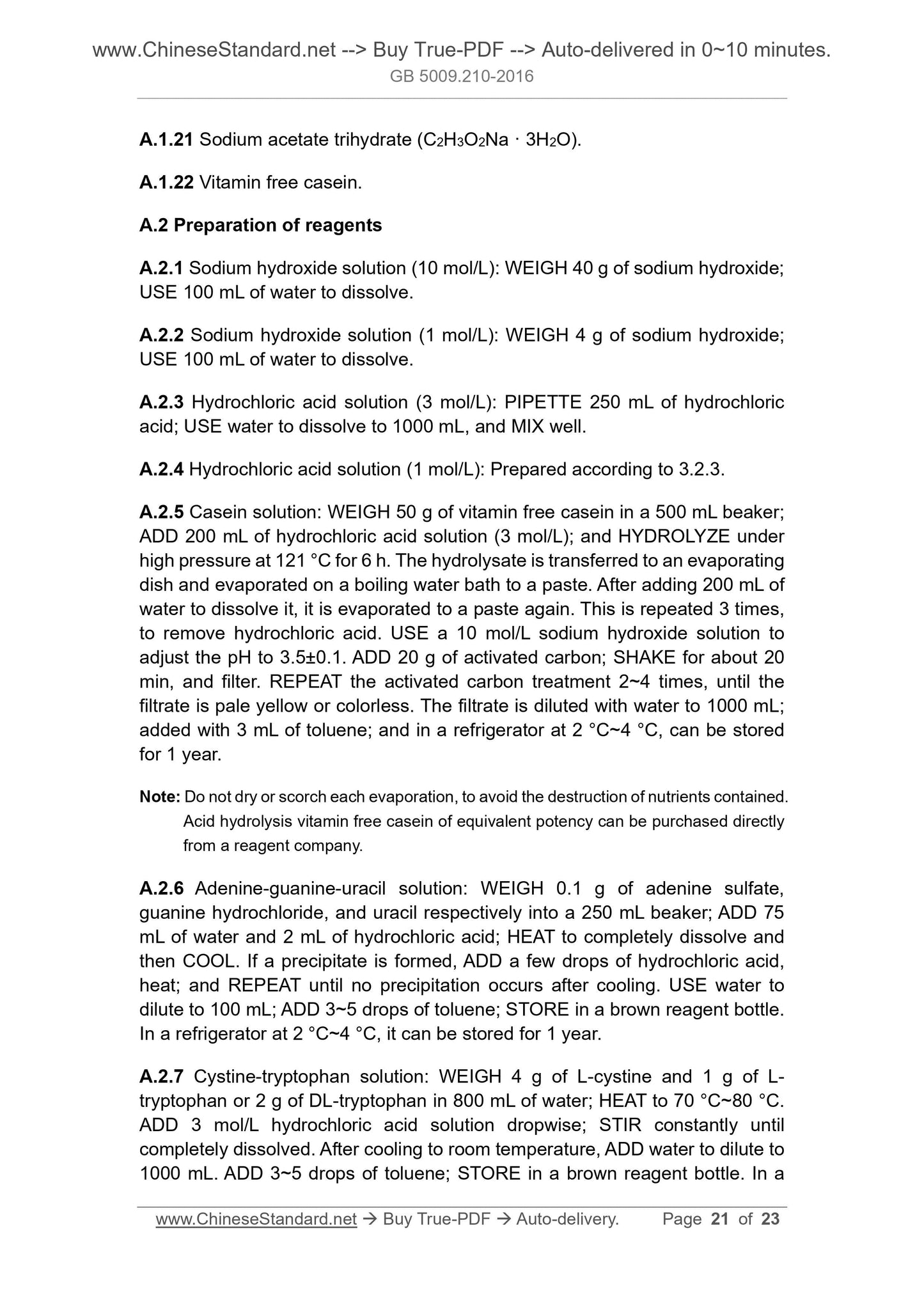

GB 5009.210-2016: Determination of pantothenic acid in foods

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB 5009.210-2016 (Self-service in 1-minute)

Newer / historical versions: GB 5009.210-2016

Preview True-PDF

Scope

This Standard specifies the method for determination of pantothenic acid andcalcium pantothenate in food.

Method 1 of this Standard is applicable to the determination of pantothenic acid

in food. Method 2 is applicable to the determination of pantothenic acid (calcium)

in nutrient supplement health foods and formula foods.

Method 1 Microbiological method

Basic Data

| Standard ID | GB 5009.210-2016 (GB5009.210-2016) |

| Description (Translated English) | Determination of pantothenic acid in foods |

| Sector / Industry | National Standard |

| Classification of Chinese Standard | C53 |

| Word Count Estimation | 15,161 |

| Date of Issue | 2016-08-31 |

| Date of Implementation | 2017-03-01 |

| Older Standard (superseded by this standard) | GB/T 5009.210-2008 |

| Regulation (derived from) | Announcement of the State Administration of Public Health and Family Planning 2016 No.11 |

| Issuing agency(ies) | National Health and Family Planning Commission of the People's Republic of China, State Food and Drug Administration |

Share