1

/

of

10

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB 5009.16-2023 English PDF

GB 5009.16-2023 English PDF

Regular price

$215.00

Regular price

Sale price

$215.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

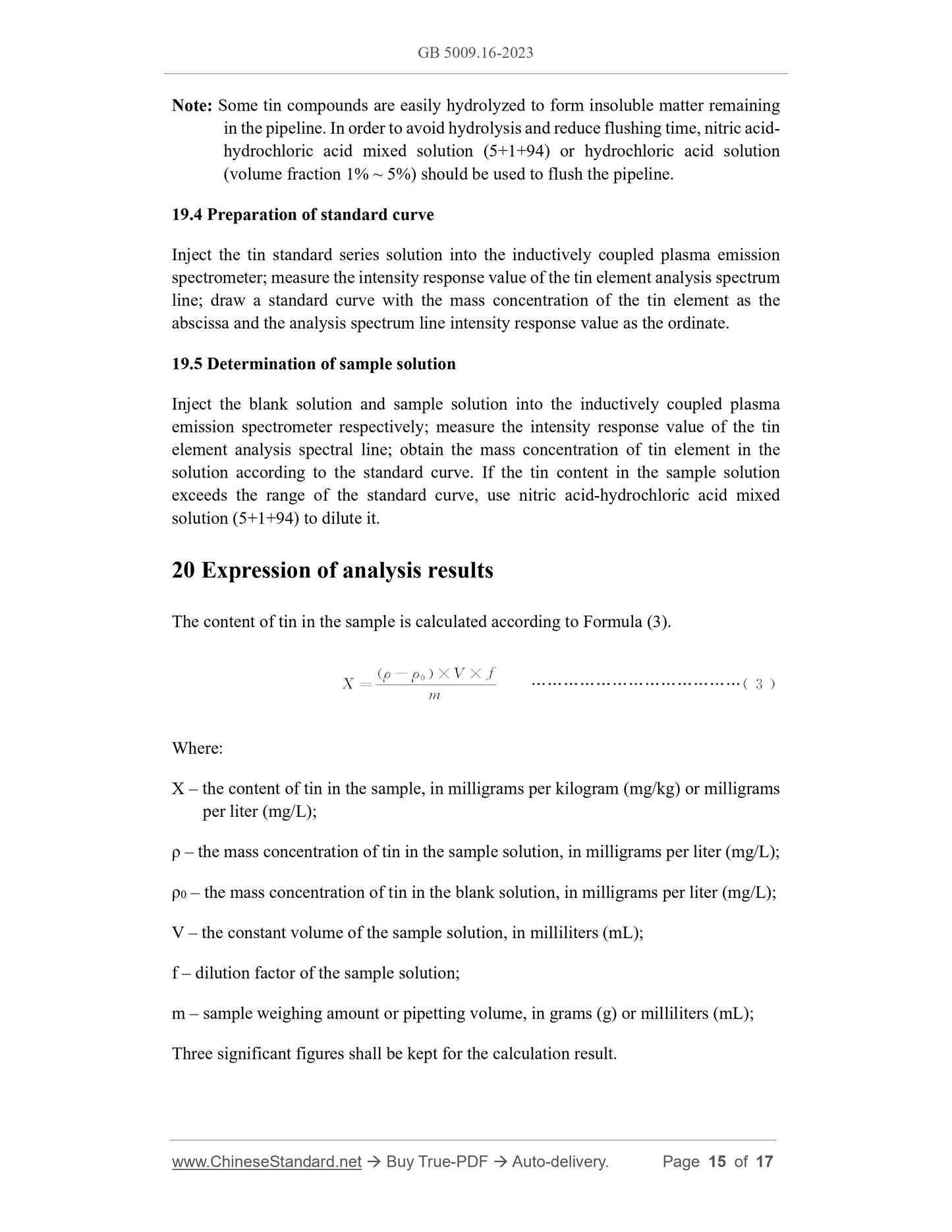

GB 5009.16-2023: National food safety standard - Determination of tin in foods

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB 5009.16-2023 (Self-service in 1-minute)

Newer / historical versions: GB 5009.16-2023

Preview True-PDF

Scope

This Standard specifies the methods for the determination of tin in foods by hydrideatomic fluorescence spectrometry, inductively coupled plasma mass spectrometry and

inductively coupled plasma-atomic emission spectrometry.

This Standard applies to the determination of tin in foods.

Method I – Hydride atomic fluorescence spectrometry

Basic Data

| Standard ID | GB 5009.16-2023 (GB5009.16-2023) |

| Description (Translated English) | National food safety standard - Determination of carmine cochineal in foods |

| Sector / Industry | National Standard |

| Classification of Chinese Standard | X09 |

| Word Count Estimation | 6,687 |

| Date of Issue | 2023-09-06 |

| Date of Implementation | 2024-03-06 |

| Issuing agency(ies) | National Health Commission of the People's Republic of China, State Administration for Market Regulation |

| Summary | This standard specifies the liquid chromatography method for the determination of cochineal in food. This standard applies to the determination of cochineal in food. |

Share