1

/

of

6

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB 36893-2018 English PDF

GB 36893-2018 English PDF

Regular price

$135.00

Regular price

Sale price

$135.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

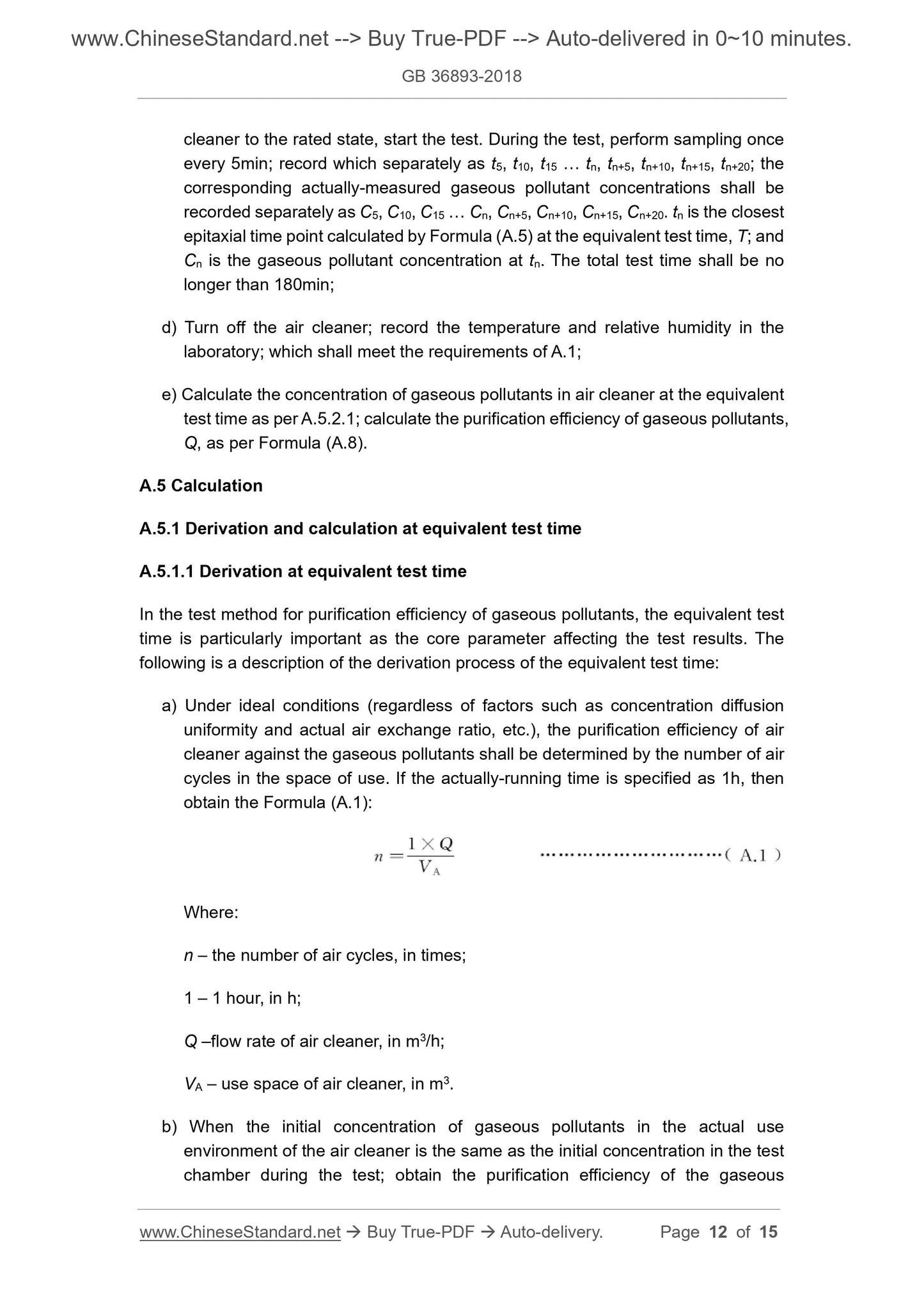

GB 36893-2018: Minimum Allowable Values of Energy Efficiency and Energy Efficiency Grades for Air Cleaners

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB 36893-2018 (Self-service in 1-minute)

Newer / historical versions: GB 36893-2018

Preview True-PDF

Scope

This Standard specifies the minimum allowable values of energy efficiency, energyefficiency grades, test and calculation methods of air cleaners.

This Standard is applicable to the air cleaners with rated voltage not exceeding 250V,

having certain particle matter cleaning capabilities (clean air delivery rate of particle is

50m3/h~800m3/h).

This Standard isn’t applicable to.

--- Air cleaners using only ion generation technology;

--- Airway air cleaning device and other similar air cleaners;

--- Air cleaners with only gas pollutants and microbial cleaning capabilities;

--- Air cleaners designed for industrial use, medical use and vehicles;

--- Air cleaners used in special environmental places such as corrosive or explosive

gases (such as dust, steam or gas).

Basic Data

| Standard ID | GB 36893-2018 (GB36893-2018) |

| Description (Translated English) | Minimum Allowable Values of Energy Efficiency and Energy Efficiency Grades for Air Cleaners |

| Sector / Industry | National Standard |

| Classification of Chinese Standard | F01 |

| Classification of International Standard | 27.010 |

| Word Count Estimation | 14,168 |

| Date of Issue | 2018-11-19 |

| Date of Implementation | 2019-12-01 |

| Regulation (derived from) | National Standard Announcement No. 15 of 2018 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share