1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB 31604.49-2023 English PDF

GB 31604.49-2023 English PDF

Regular price

$335.00

Regular price

Sale price

$335.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB 31604.49-2023: National food safety standard - Food contact materials and products - Determination of multi-elements and determination of multi-element migration

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB 31604.49-2023 (Self-service in 1-minute)

Newer / historical versions: GB 31604.49-2023

Preview True-PDF

Scope

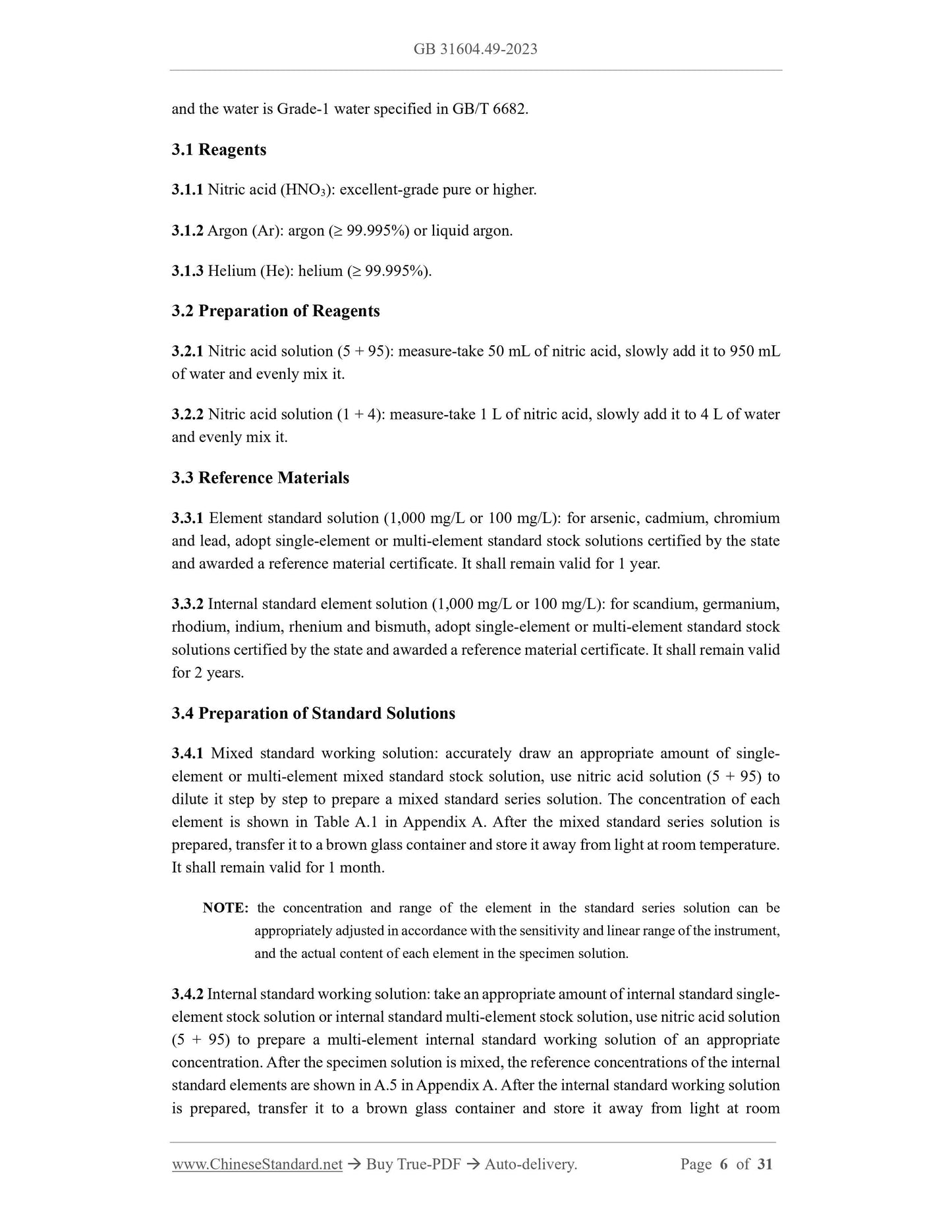

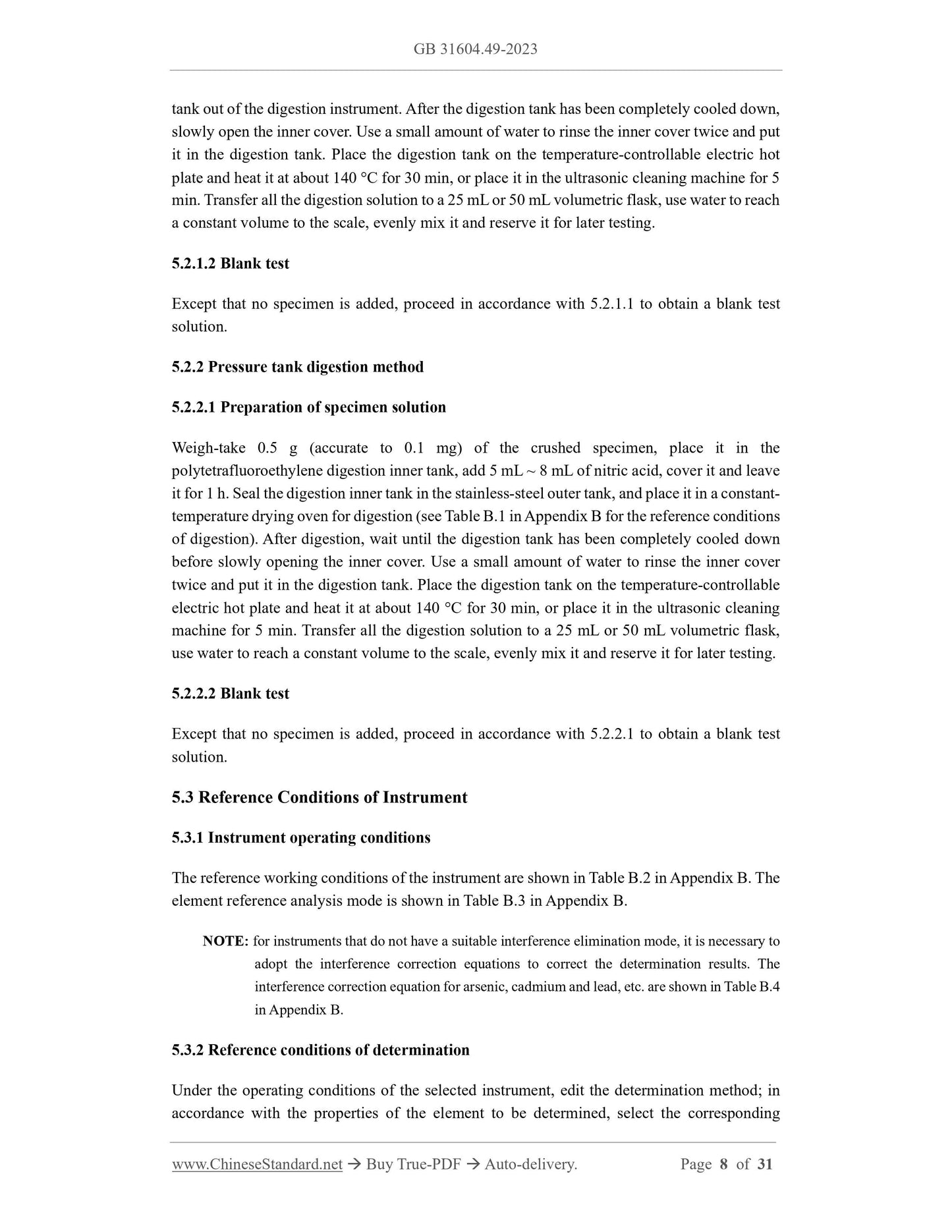

This Standard specifies the method for the determination of arsenic, cadmium, chromium andlead, and the determination of aluminum, arsenic, barium, cadmium, cobalt, chromium, copper,

iron, lithium, manganese, molybdenum, nickel, lead, antimony, tin and zinc migration in food

contact materials and products.

Part 1 is applicable to the determination of arsenic, cadmium, chromium and lead in food

contact paper and cardboard materials and products, cork stoppers and bamboo and wood

products.

Part 2 is applicable to the determination of aluminum, arsenic, barium, cadmium, cobalt,

chromium, copper, iron, lithium, manganese, molybdenum, nickel, lead, antimony, tin and zinc

migration in food contact plastic materials and products, food contact paints and coatings, food

contact rubber materials and products, inks for food contact materials and products, adhesives

for food contact materials and products, food contact paper and cardboard materials, pacifiers,

enamel products, ceramic products, glass products, food contact plastic resins, food contact

metal materials and products.

Part 1 - Determination of Arsenic, Cadmium, Chromium

and Lead

Method 1 Inductively Coupled Plasma Mass Spectrometry

Basic Data

| Standard ID | GB 31604.49-2023 (GB31604.49-2023) |

| Description (Translated English) | National food safety standard - Food contact materials and products - Determination of migration of benzophenone substances |

| Sector / Industry | National Standard |

| Classification of Chinese Standard | X09 |

| Word Count Estimation | 20,249 |

| Date of Issue | 2023-09-06 |

| Date of Implementation | 2024-03-06 |

| Issuing agency(ies) | National Health Commission of the People's Republic of China, State Administration for Market Regulation |

| Summary | This standard specifies the determination method for the migration of 8 benzophenones in food contact materials and products. The first method liquid chromatography is suitable for (2-hydroxy-4-methoxyphenyl) (2-hydroxyphenyl) methanone, 2,4-dihydroxybenzophenone, (2-hydroxy-4-methoxyphenyl)phenylmethanone, 4,4'-dihydroxybenzophenone, 2-hydroxy-4-n-octyloxy benzophenone, 2-hydroxy-4-n-hexyloxybenzophenone, benzophenone and 4,4'-difluorobenzophenone in water, 4% (volume fraction) acetic acid, 10% (volume fraction) ethanol, 20 (volume fraction) ethanol, 50 (volume fraction) ethanol food simulants, and chemical alternative solvents |

Share