1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB 31604.18-2016 English PDF

GB 31604.18-2016 English PDF

Regular price

$70.00

Regular price

Sale price

$70.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB 31604.18-2016: National food safety standard - Food contact materials and articles - Determination of migration of acrylamide

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB 31604.18-2016 (Self-service in 1-minute)

Newer / historical versions: GB 31604.18-2016

Preview True-PDF

Scope

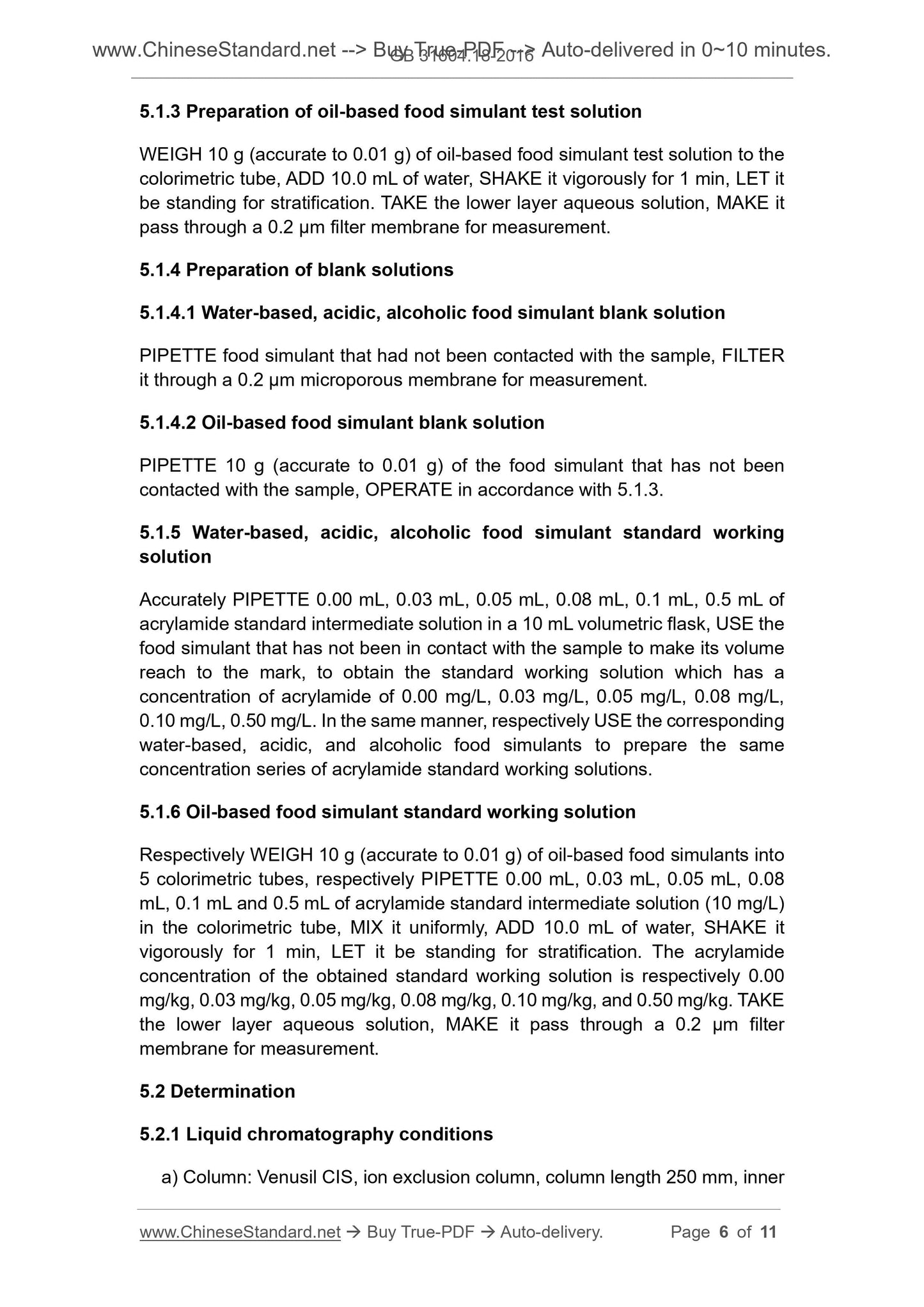

This standard specifies the determination of the migration of acrylamide in foodcontact materials and articles.

This standard applies to the use of liquid chromatography for the detection of

acrylamide migration in food contact materials and articles.

2 Principle

The food simulants of food contact materials and articles are tested by liquid

chromatography, wherein the water-based, acidic, and alcoholic food simulants

are directly injected, the oil-based food simulants are injected after water

extraction and separated through high-performance liquid chromatography.

(The column is an ion exclusion column), detected by a UV detector, and it is

quantified using the external standard peak area method.

Basic Data

| Standard ID | GB 31604.18-2016 (GB31604.18-2016) |

| Description (Translated English) | National food safety standard - Food contact materials and articles - Determination of migration of acrylamide |

| Sector / Industry | National Standard |

| Classification of Chinese Standard | C53 |

| Word Count Estimation | 8,858 |

| Date of Issue | 2016-10-19 |

| Date of Implementation | 2017-04-19 |

| Older Standard (superseded by this standard) | GB/T 23296.9-2009 |

| Regulation (derived from) | State Health and Family Planning Commission Notice No.1516 of 2016 |

| Issuing agency(ies) | National Health and Family Planning Commission of the People's Republic of China, State Food and Drug Administration |

Share