1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB 31572-2015 English PDF

GB 31572-2015 English PDF

Regular price

$145.00

Regular price

Sale price

$145.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB 31572-2015: Emission standard of pollutants for synthetic resin industry

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB 31572-2015 (Self-service in 1-minute)

Newer / historical versions: GB 31572-2015

Preview True-PDF

Scope

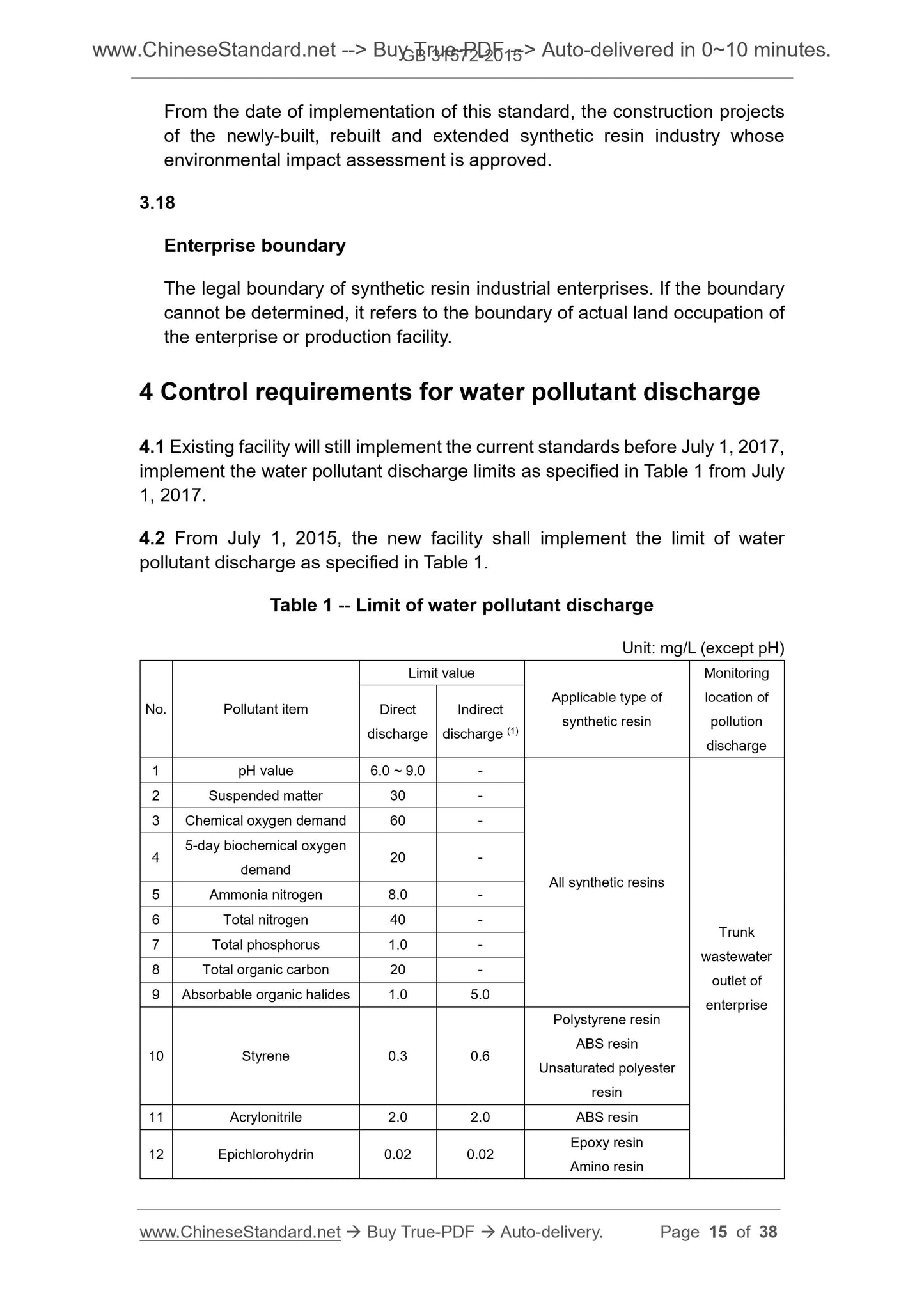

This standard specifies the emission limits, monitoring, supervision andmanagement requirements for water pollutants and air pollutants from synthetic

resin industrial enterprises and their production facilities (including the

enterprises for synthetic resin processing and waste synthetic resin recycling

and processing as well as their production facilities).

This standard is applicable to the management of emission of water pollutants

and air pollutants in existing synthetic resin industrial enterprises or production

facilities, as well as the environmental impact assessment of synthetic resin

industrial construction projects, the design of environmental protection facilities,

the completion environmental protection acceptance, and the management of

emission of water pollutant and air pollutant after it is put into operation.

The monomer production equipment in the synthetic resin enterprise

implements the “Emission standards for pollutant of petrochemical industry”,

the production equipment of polyvinyl chloride resin (PVC) implements the

“Emission standards for emission of caustic soda and polyvinyl chloride

industry”.

This standard applies to the discharge of pollutants permitted by law. For the

selection of location of the newly-established pollution sources and the

management of the existing pollution source within the specially protected

regions, it shall follow the relevant provisions of such laws, regulations and rules

as the Water pollution prevention and control law of the People’s Republic of

China, the Air pollution prevention and control law of the People’s Republic of

China, the Marine environmental protection law of the People’s Republic of

China, the Law of the People's Republic of China on environmental pollution by

solid wastes, the Law of the People's Republic of China on environmental

impact assessment.

Basic Data

| Standard ID | GB 31572-2015 (GB31572-2015) |

| Description (Translated English) | Emission standard of pollutants for synthetic resin industry |

| Sector / Industry | National Standard |

| Classification of Chinese Standard | Z60 |

| Classification of International Standard | 13.040.40 |

| Word Count Estimation | 24,246 |

| Date of Issue | 2015-04-16 |

| Date of Implementation | 2015-07-01 |

| Quoted Standard | GB/T 6920; GB/T 7466; GB/T 7467; GB/T 7469; GB/T 7470; GB/T 7471; GB/T 7475; GB/T 7484; GB/T 7485; GB/T 8017; GB/T 11890; GB/T 11893; GB/T 11901; GB/T 11910; GB/T 11912; GB/T 11914; GB/T 14204; GB/T 14678; GB/T 15432; GB/T 15516; GB/T 15959; GB/T 16157; HJ/T 27; HJ/T 31; HJ/T 32; HJ/T 35; HJ/T 37; HJ/T 38; HJ/T 39; HJ/T 42; HJ/T 43; HJ/T 55; HJ/T 56; HJ/T 57; HJ/T 66; HJ/T 67; HJ/T 70; HJ/T 73; HJ/T 74; HJ/T 75; HJ/T 76; HJ 77.2; HJ/T 83; HJ/T 91; HJ/T 132; HJ/T 195; HJ/T 373; HJ/T 397; HJ/T 399; HJ 484; HJ 487; HJ 488; HJ 493; HJ 494; HJ 495; HJ 501; HJ 505; HJ 533; HJ 535; HJ 536; HJ 537; HJ 548; HJ 549; HJ 583; HJ 584; HJ 597; HJ 601; HJ 620; HJ 621; HJ 629; HJ 636; HJ 639; HJ 644; HJ 665; HJ 666; HJ 667; HJ 668; HJ 670; HJ 671; HJ 675; HJ 676; HJ 686; HJ 688; HJ 692; HJ 693; HJ 694; HJ 700; HJ 732; HJ 733; HJ 734 |

| Regulation (derived from) | Ministry of Environmental Protection Announcement 2015 No. 27: National Standard Announcement 2015 No. 15 |

| Issuing agency(ies) | Ministry of Environmental Protection, General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China |

| Summary | This Standard specifies the synthetic resin industry enterprises and production facilities (including synthetic resin, synthetic resin processing and waste recycling and processing enterprises and production facilities) of water pollutants and air pollutants emission limits, monitoring and supervision requirements. Environmental Impact Assessment This Standard applies to existing industrial enterprises or synthetic resin production facilities of water pollutants and air pollutant emissions management, as well as synthetic resin industrial construction projects, environmental protection facilities design, completion and acceptance of environmental protection and water after putting into operation atmospheric pollutants and pollutant emissions management. Executive synthetic resin monomer production plant within the enterprise, "the petrochemical industry emission standards", polyvinyl chloride resin (PVC) production plant Execution (caustic soda and polyvinyl chloride industry emission standards). This Standard applies to pollution discharge permitted by law. |

Share