1

/

of

9

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB 1903.63-2023 English PDF

GB 1903.63-2023 English PDF

Regular price

$185.00

Regular price

Sale price

$185.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB 1903.63-2023: National food safety standard - Food nutritional fortification - Calcium glycerophosphate

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB 1903.63-2023 (Self-service in 1-minute)

Newer / historical versions: GB 1903.63-2023

Preview True-PDF

Scope

This Standard applies to calcium glycerophosphate, the food nutritional enhancerobtained by neutralizing glycerophosphate with calcium hydroxide or calcium

carbonate.

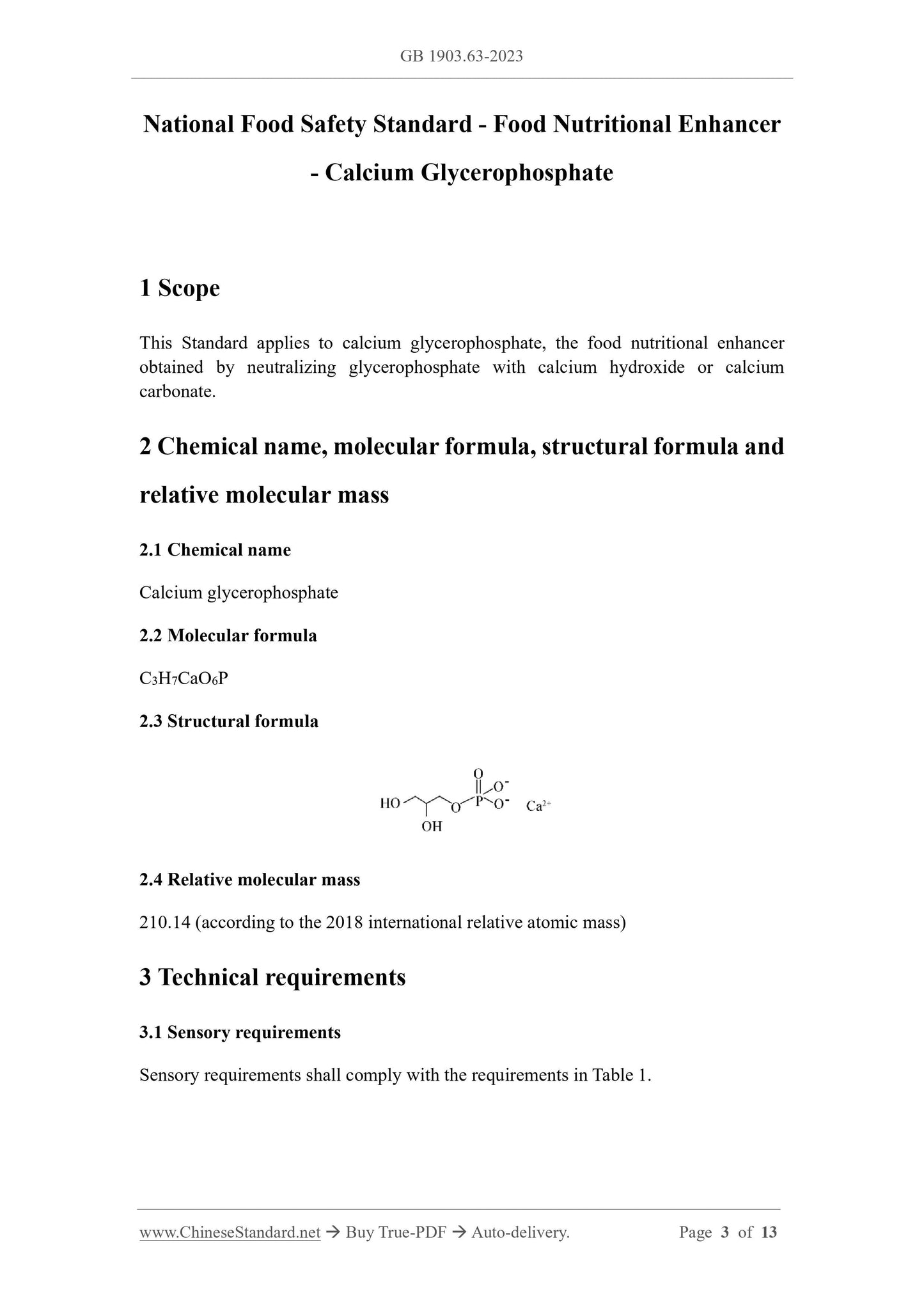

2 Chemical name, molecular formula, structural formula and

relative molecular mass

2.1 Chemical name

Calcium glycerophosphate

2.2 Molecular formula

C3H7CaO6P

2.3 Structural formula

2.4 Relative molecular mass

210.14 (according to the 2018 international relative atomic mass)

Basic Data

| Standard ID | GB 1903.63-2023 (GB1903.63-2023) |

| Description (Translated English) | (National Food Safety Standards Food Nutritional Enhancers Reduced Iron) |

| Sector / Industry | National Standard |

| Classification of Chinese Standard | X09 |

| Word Count Estimation | 8,868 |

| Date of Issue | 2023-09-06 |

| Date of Implementation | 2024-03-06 |

| Issuing agency(ies) | National Health Commission of the People's Republic of China, State Administration for Market Regulation |

| Summary | This standard applies to food nutrition fortifier reduced iron produced by coal-based direct reduction method or gas-based direct reduction method using iron phosphorus or iron concentrate powder as raw materials. |

Share