1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB 1886.363-2022 English PDF

GB 1886.363-2022 English PDF

Regular price

$110.00

Regular price

Sale price

$110.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB 1886.363-2022: National food safety standard - Food additive - Plant activated carbon (Rice husk activated carbon)

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB 1886.363-2022 (Self-service in 1-minute)

Newer / historical versions: GB 1886.363-2022

Preview True-PDF

Scope

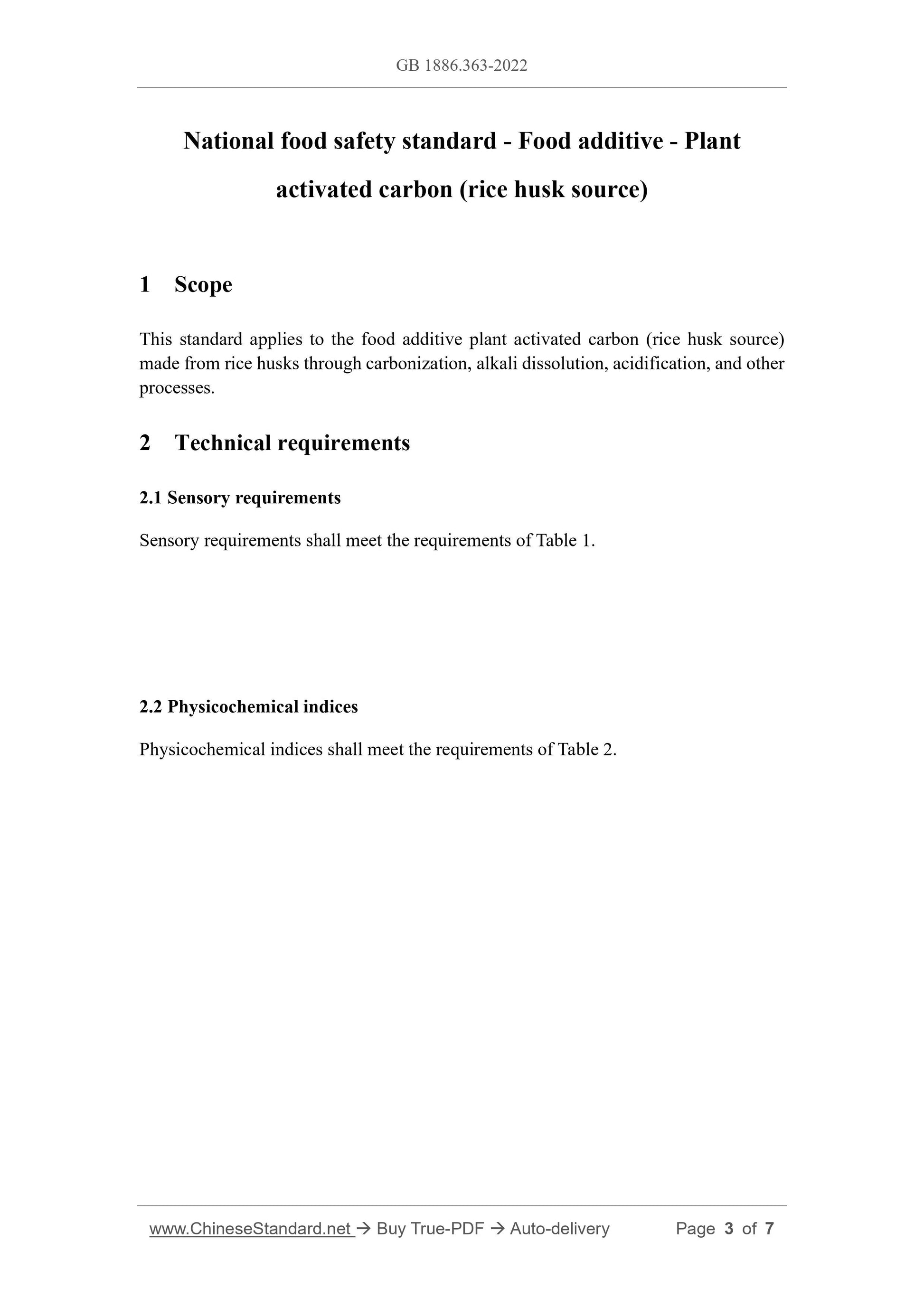

This standard applies to the food additive plant activated carbon (rice husk source)made from rice husks through carbonization, alkali dissolution, acidification, and other

processes.

Basic Data

| Standard ID | GB 1886.363-2022 (GB1886.363-2022) |

| Description (Translated English) | National food safety standard - Food additive - Plant activated carbon (Rice husk activated carbon) |

| Sector / Industry | National Standard |

| Classification of Chinese Standard | X09 |

| Word Count Estimation | 6,610 |

| Issuing agency(ies) | National Health Commission of the People's Republic of China, State Administration for Market Regulation |

Share