1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB 1886.174-2016 English PDF

GB 1886.174-2016 English PDF

Regular price

$230.00

Regular price

Sale price

$230.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

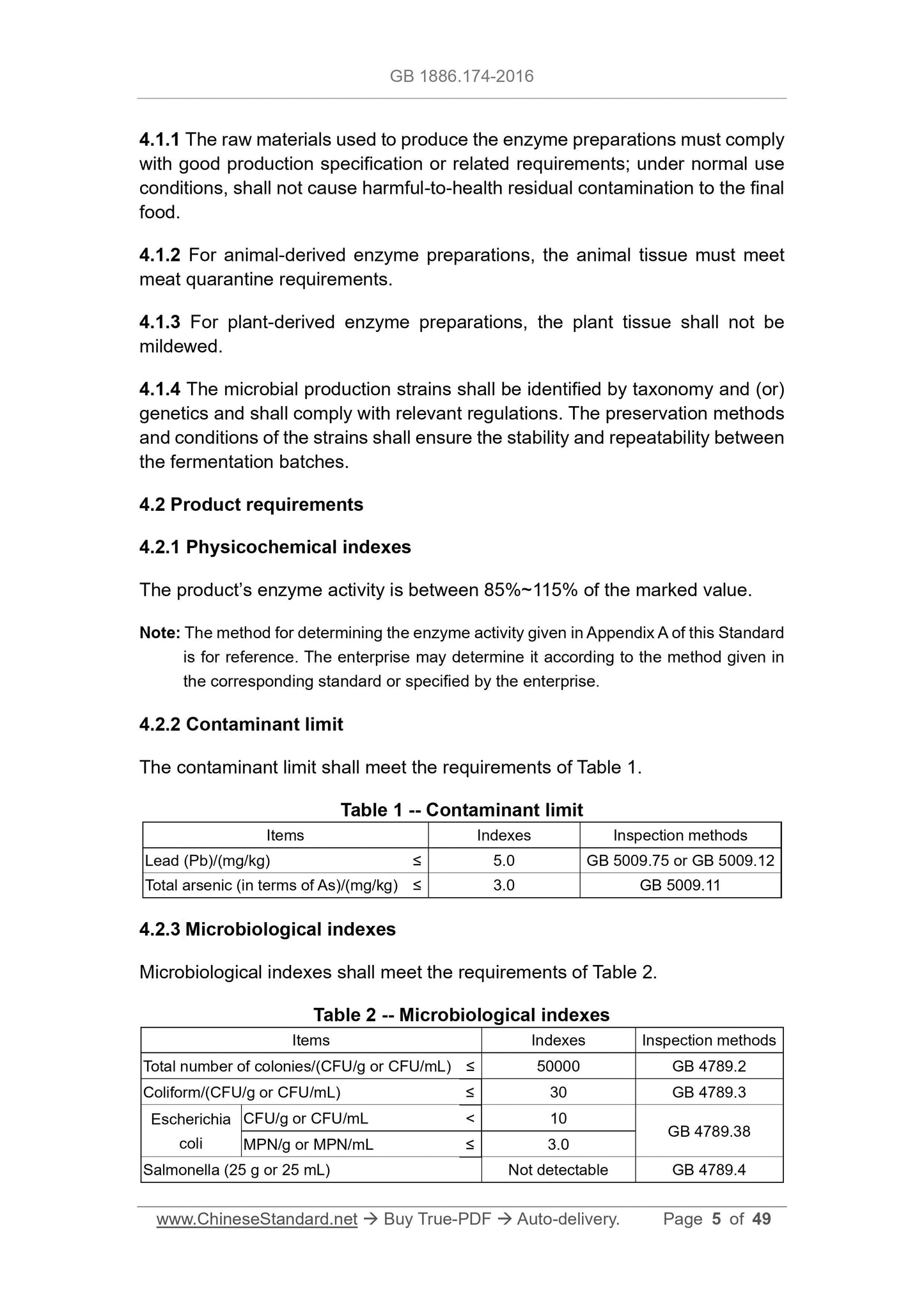

GB 1886.174-2016: National food safety standard - Food additives - Enzyme preparation for food industry

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB 1886.174-2016 (Self-service in 1-minute)

Newer / historical versions: GB 1886.174-2016

Preview True-PDF

Scope

This Standard applies to the enzyme preparation for food industry allowed byGB 2760.

Basic Data

| Standard ID | GB 1886.174-2016 (GB1886.174-2016) |

| Description (Translated English) | National food safety standard - Food additives - Enzyme preparation for food industry |

| Sector / Industry | National Standard |

| Classification of Chinese Standard | X42 |

| Word Count Estimation | 33,365 |

| Date of Issue | 2016-08-31 |

| Date of Implementation | 2017-01-01 |

| Older Standard (superseded by this standard) | GB 8276-2006; GB 8275-2009; GB 25594-2010; GB 20713-2006 |

| Regulation (derived from) | Announcement of the State Administration of Public Health and Family Planning 2016 No.11 |

| Issuing agency(ies) | National Health and Family Planning Commission of the People's Republic of China, State Food and Drug Administration |

Share