1

/

of

10

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

DB13/ 2322-2016 English PDF (DB13/2322-2016)

DB13/ 2322-2016 English PDF (DB13/2322-2016)

Regular price

$445.00

Regular price

Sale price

$445.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

DB13/ 2322-2016: Emission Control Standard of Volatile Organic Compounds for Industrial Enterprises

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click DB13/ 2322-2016 (Self-service in 1-minute)

Newer / historical versions: DB13/ 2322-2016

Preview True-PDF

Scope

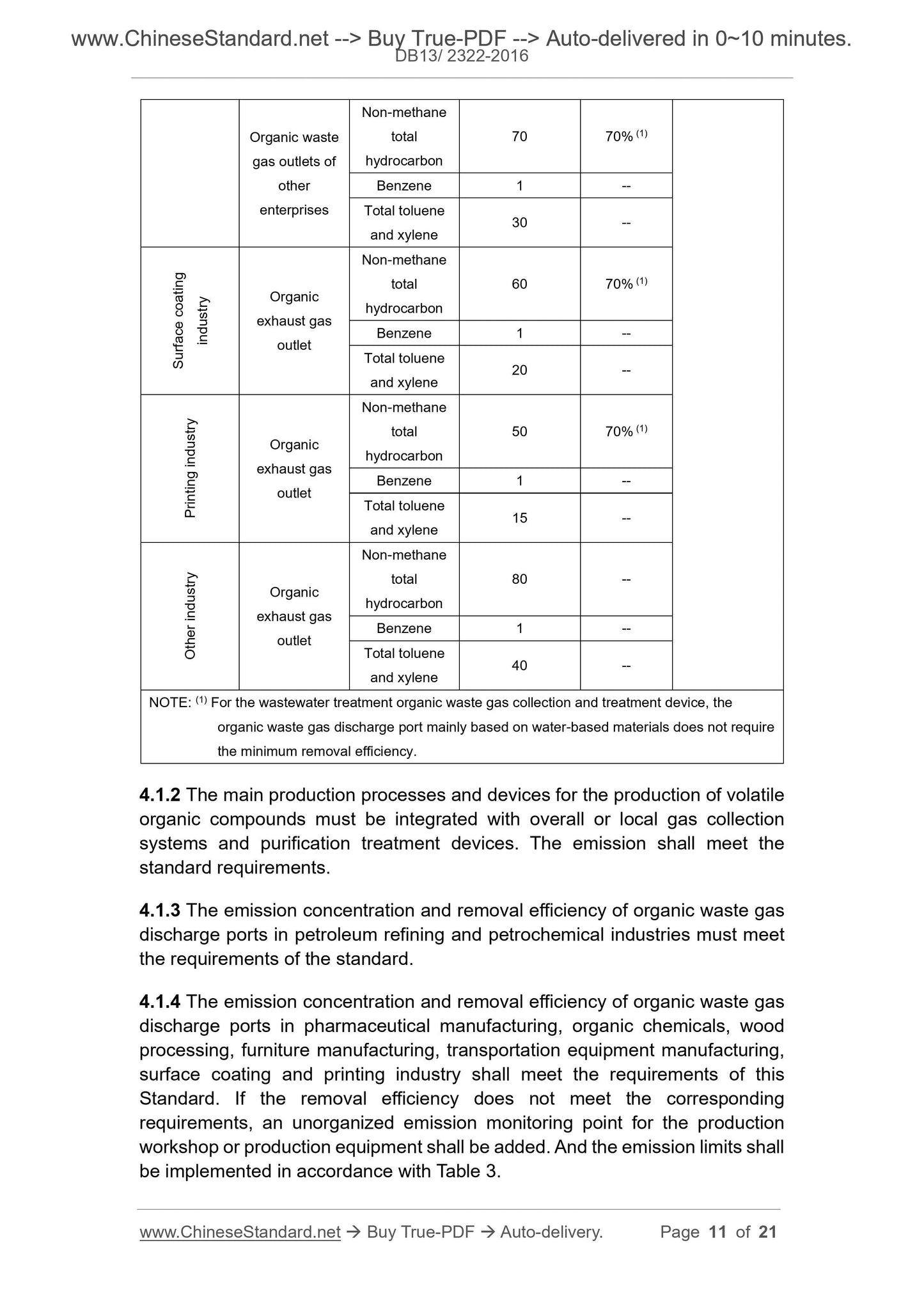

This Standard specifies the control requirements, pollutant monitoringrequirements, implementation and supervision requirements for emission

control standard of volatile organic compounds.

This Standard is applicable to emission management of volatile organic

compounds in waste gas from existing and new industrial enterprises or

production facilities; as well as construction projects’ environmental impact

assessment, design of environmental protection facilities, completion

acceptance of environmental protection AND discharge management of volatile

organic compounds after-production.

Basic Data

| Standard_ID | DB13/ 2322-2016 (DB13/2322-2016; DB13 2322-2016; DB132322-2016) |

| Description (Translated English) | (Industrial enterprise volatile organic matter emission control standards) |

| Sector / Industry | Provincial-Local Standard |

| Date of Issue | 24/2/2016 |

| Date of Implementation | 24/2/2016 |

| Administrative Organization | Hebei Provincial Bureau of Quality and Technical Supervision |

Share