1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

CNCA 00C-006-2014 English PDF

CNCA 00C-006-2014 English PDF

Regular price

$175.00

Regular price

Sale price

$175.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

CNCA 00C-006-2014: Compulsory product certification and implementation rules - General requirements for factory inspection

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click CNCA 00C-006-2014 (Self-service in 1-minute)

Newer / historical versions: CNCA 00C-006-2014

Preview True-PDF

Scope

10.1 Requirements for the application of CCC mark during productionprocess

10.2 Requirements for entrusting relevant parties to print and mold CCC

mark

11.1 Factory inspection conclusions and classification of nonconforming

items

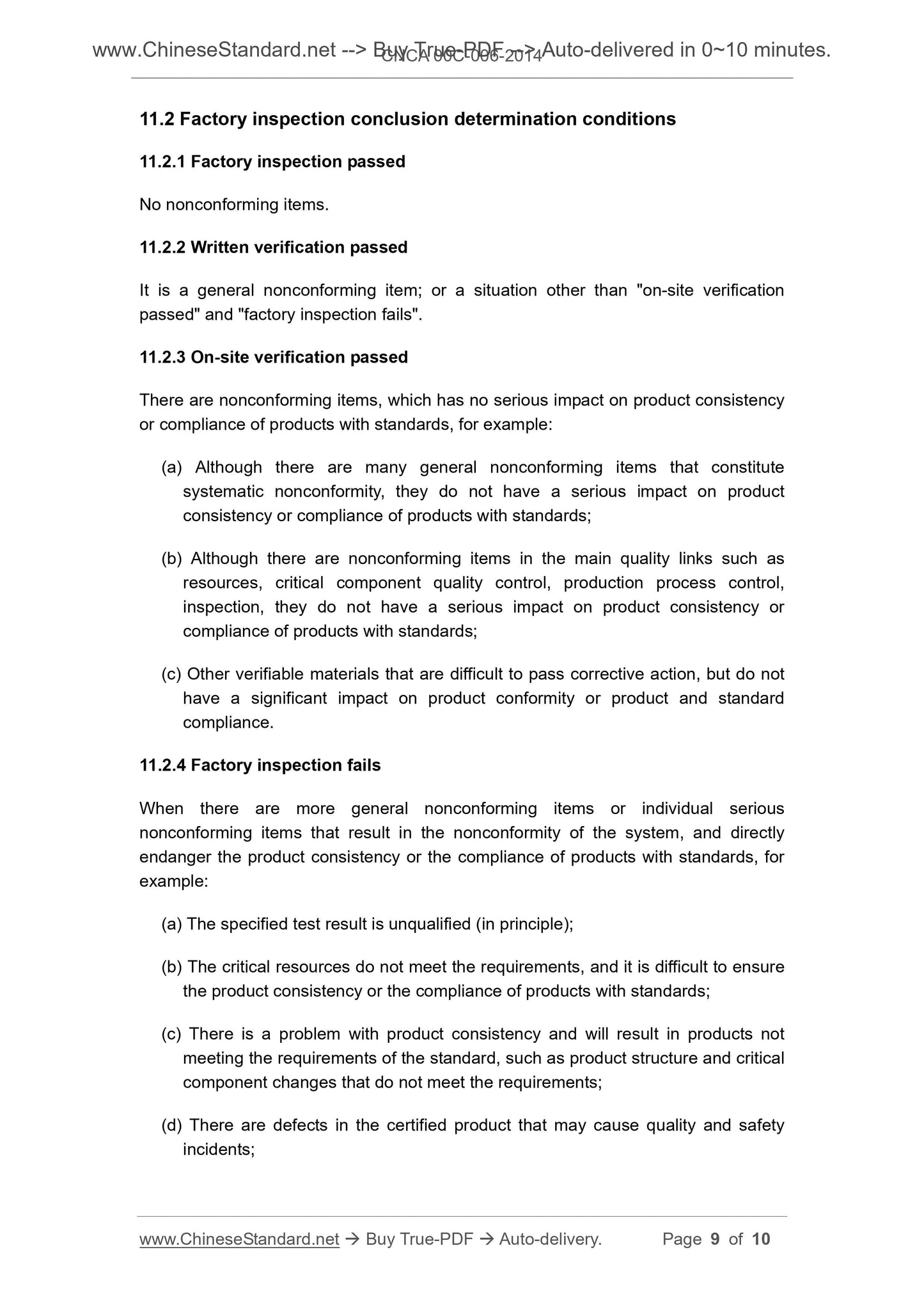

11.2 Factory inspection conclusion determination conditions

11.2.1 Factory inspection passed

No nonconforming items.

11.2.2 Written verification passed

It is a general nonconforming item; or a situation other than "on-site verification

passed" and "factory inspection fails".

Announcement of Certification and Accreditation

Administration on Issuing China Compulsory Certification

Implementation Rules such as Factory Quality Assurance

Capability Requirements

No. 1, 2014

In order to further promote scientific, standardize and effective implementation of

China compulsory certification, according to the “Regulations of the People's Republic

of China on Certification and Accreditation”, “Regulation Concerning Management of

Compulsory Product Certification" and “Notice of Certification and Accreditation

Administration on Clarifying the Adjustment Plan and Requirements for China

Compulsory Certification Implementation Documents” (CNCA [2013] No. 39), CNCA

has formulated two general implementation rules for China compulsory certification.

“China Compulsory Certification Implementation Rules - Factory Quality Assurance

Capacity Requirements”, which is used to normatively guide the manufacturing

enterprise of the products in the compulsory certification catalogue to establish quality

assurance capacity to ensure that the products sustain the compliance with the CCC

certification requirements; “China Compulsory Certification Implementation Rules -

General Requirements for Factory Inspection”, which is used to normatively guide the

consistency of the implementation of the factory inspection work of the designated

certification body of compulsory certification, which are issued now.

The above two general implementation rules are used in conjunction with the specific

product certification implementation rules issued subsequently, and will be

implemented on September 1, 2014.

Basic Data

| Standard ID | CNCA 00C-006-2014 (CNCA-00C-006-2014) |

| Description (Translated English) | Compulsory product certification and implementation rules - General requirements for factory inspection |

| Sector / Industry | China Compulsory Certification (CCC) Implementation Rules |

| Classification of Chinese Standard | A00 |

| Classification of International Standard | CNCA Notice No. 1 of 2014 |

| Word Count Estimation | 10,123 |

| Date of Issue | 2014-01-02 |

| Date of Implementation | 2014-09-01 |

| Regulation (derived from) | CNCA Notice No. 1 of 2014 |

| Issuing agency(ies) | China National Accreditation Administration for Certification and Accreditation |

| Summary | This standard specifies the China Compulsory Certification (CCC) implementation rules for Factory inspection general requirements. |

Share