1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

CCGF 201.15-2015 English PDF

CCGF 201.15-2015 English PDF

Regular price

$140.00

Regular price

Sale price

$140.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

CCGF 201.15-2015: Electric Pressure Cooker

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click CCGF 201.15-2015 (Self-service in 1-minute)

Newer / historical versions: CCGF 201.15-2015

Preview True-PDF

Scope

This Specification is applicable to national supervision and spot check of the quality ofelectric pressure cooker products. This Specification may be taken as a reference in

the implementation of special national supervision and spot check, and local

supervision and spot check organized by above-county-level local quality and technical

supervision departments under special circumstances. The scope of product

supervision and spot check includes electric pressure cooker products for household

purposes and similar purposes. The content of this Specification includes product

classification, terms and definitions, enterprise product production scale division,

inspection basis, sampling, inspection requirements, determination principles,

objection handling and supplementary provisions.

Basic Data

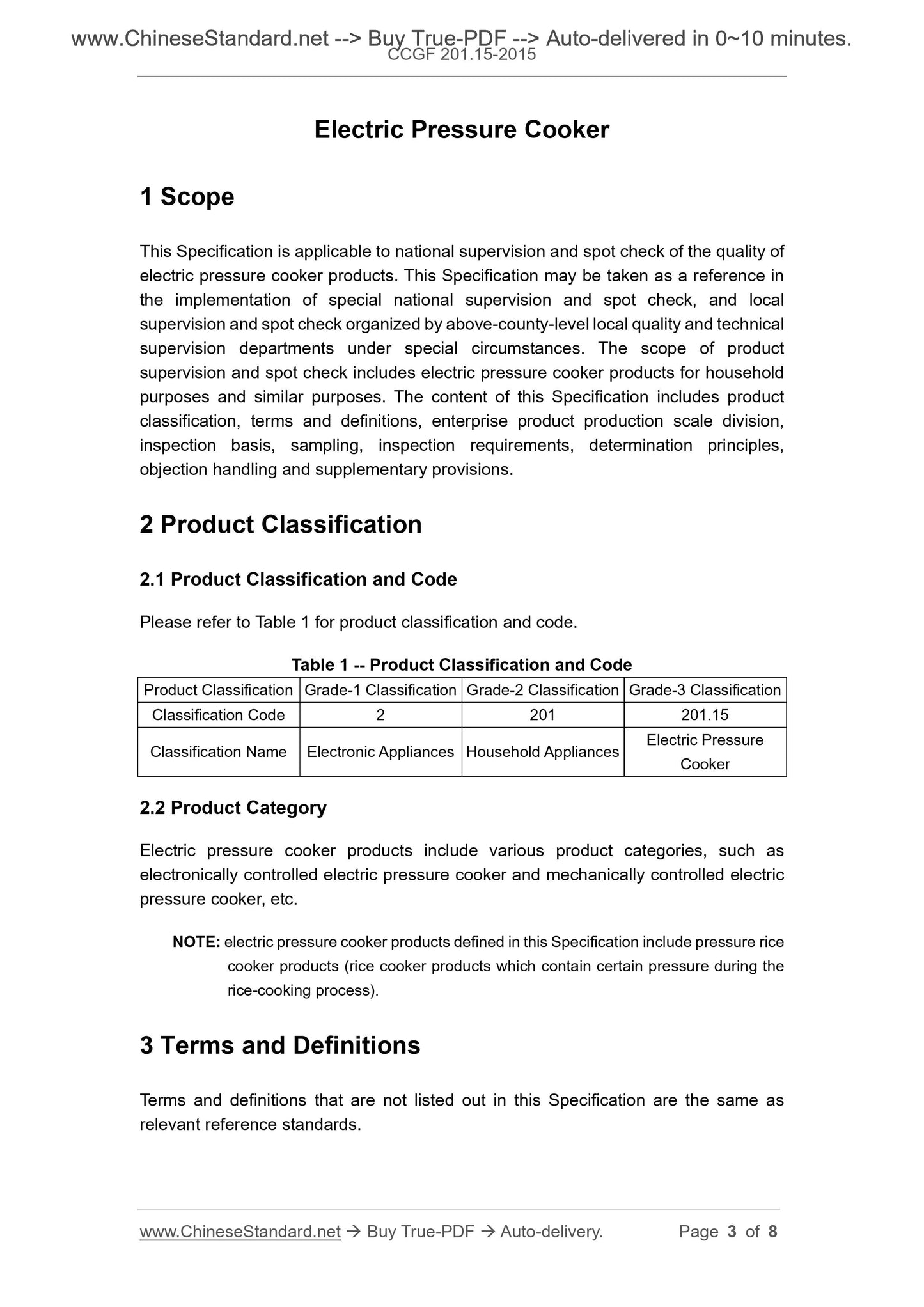

| Standard ID | CCGF 201.15-2015 (CCGF201.15-2015) |

| Description (Translated English) | Electric Pressure Cooker |

| Sector / Industry | Chinese Industry Standard |

| Classification of Chinese Standard | Y68 |

| Classification of International Standard | 97.040.99 |

| Word Count Estimation | 5,591 |

| Date of Issue | 2015-04-29 |

| Date of Implementation | 2015-06-01 |

| Older Standard (superseded by this standard) | CCGF 206.15-2010 |

| Quoted Standard | GB 4706.1-2005; GB 4706.19-2008 |

| Regulation (derived from) | AQSIQ Announcement 2015 No.54 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine |

| Summary | This standard applies to electrical pressure cookers product quality supervision and inspection, special national supervision for special circumstances, above the county level quality and technical supervision departments of the organization where supervision can be implemented by reference. Supervision product range includes household and similar purposes, pressure cookers products. This specification includes product classification, terminology and definitions, product production scale division, test basis, sampling, inspection requirements, determination principle, objection handling and By-Laws. |

Share