1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 36120-2018 English PDF (GB/T36120-2018)

GB/T 36120-2018 English PDF (GB/T36120-2018)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

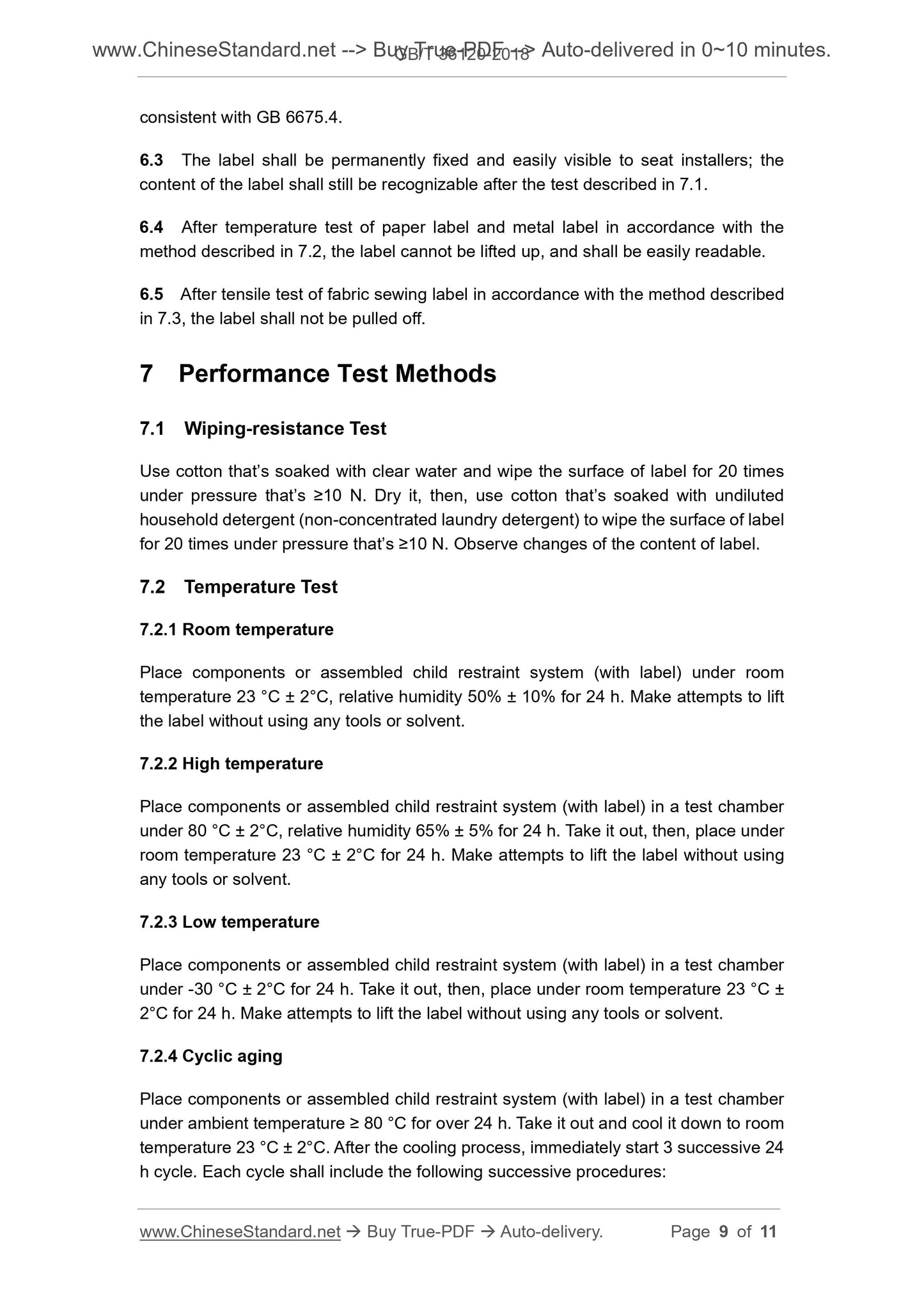

GB/T 36120-2018: Production Label for Child Restraint System of Power-driven Vehicles

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 36120-2018 (Self-service in 1-minute)

Newer / historical versions: GB/T 36120-2018

Preview True-PDF

Scope

This Standard specifies terms, definitions, content, layout, pattern, performancerequirements and experiment methods of production label for child restraint system of

power-driven vehicles.

This Standard is applicable to child restraint system products of power-driven vehicles

sold within the territory of China.

Basic Data

| Standard ID | GB/T 36120-2018 (GB/T36120-2018) |

| Description (Translated English) | Production Label for Child Restraint System of Power-driven Vehicles |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | T26 |

| Classification of International Standard | 43.040.60 |

| Word Count Estimation | 12,173 |

| Date of Issue | 2018-05-14 |

| Date of Implementation | 2018-12-01 |

| Regulation (derived from) | National Standards Announcement No. 6 of 2018 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share