1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 21655.2-2019 English PDF (GB/T21655.2-2019)

GB/T 21655.2-2019 English PDF (GB/T21655.2-2019)

Regular price

$135.00

Regular price

Sale price

$135.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 21655.2-2019: Textiles - Evaluation of absorption and quick-drying - Part 2: Method for moisture management tests

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 21655.2-2019 (Self-service in 1-minute)

Newer / historical versions: GB/T 21655.2-2019

Preview True-PDF

Scope

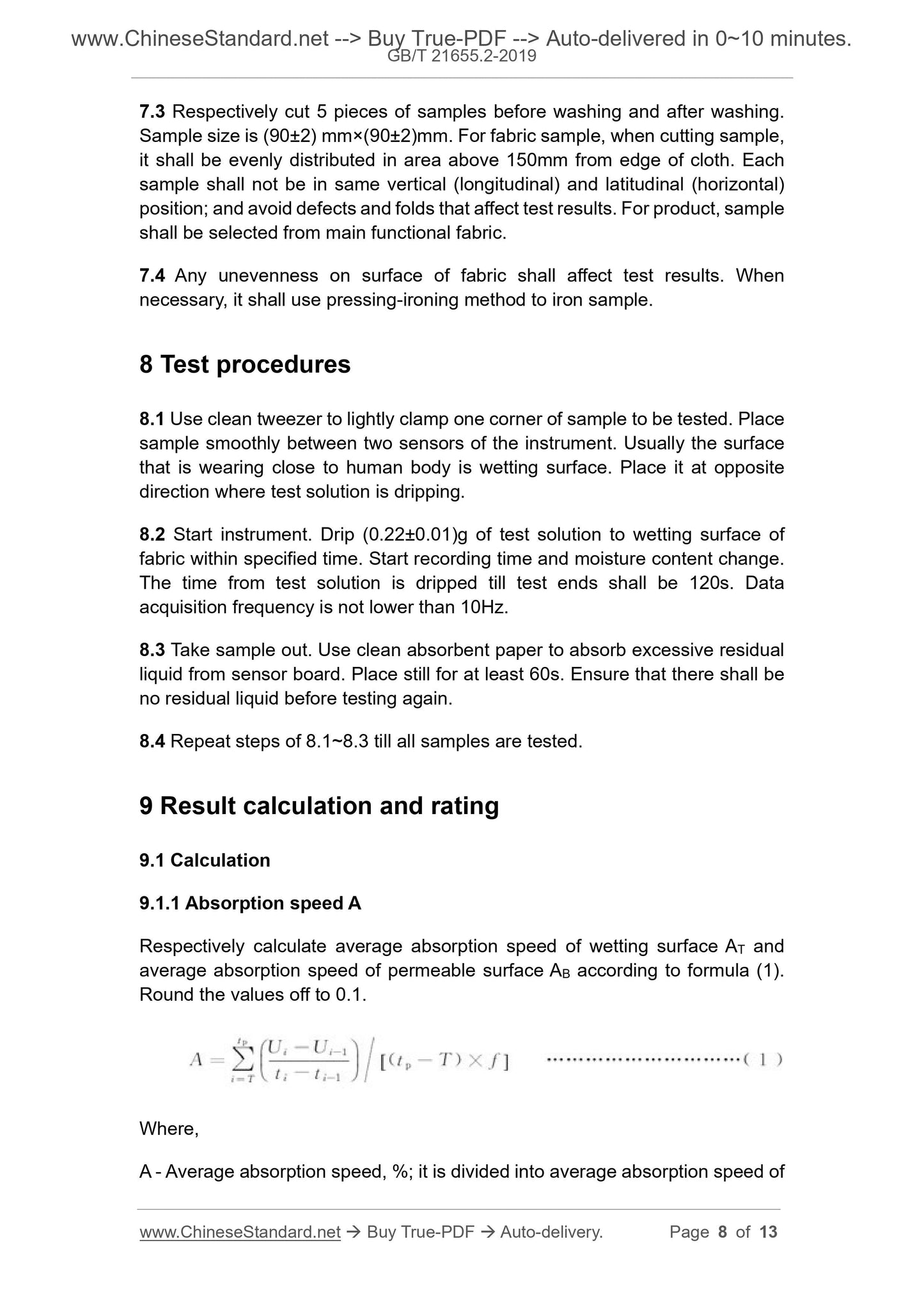

This Part of GB/T 21655 specifies method and evaluation index that usemoisture management method to determine moisture-absorption quick-drying

and moisture-absorption perspiration of textiles.

This Part is applicable to various textiles.

Basic Data

| Standard ID | GB/T 21655.2-2019 (GB/T21655.2-2019) |

| Description (Translated English) | Textiles - Evaluation of absorption and quick-drying - Part 2: Method for moisture management tests |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | W04 |

| Classification of International Standard | 59.080.30 |

| Word Count Estimation | 10,162 |

| Date of Issue | 2019-06-04 |

| Date of Implementation | 2020-01-01 |

| Older Standard (superseded by this standard) | GB/T 21655.2-2009 |

| Quoted Standard | GB/T 6529; GB/T 6682; GB/T 8629-2017 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

| Summary | This standard specifies the method and evaluation index for the determination of the moisture absorption, quick-drying and moisture-wicking properties of textiles by the liquid water dynamic transfer method. This standard applies to all types of textile products. |

Share