1

/

of

7

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 2059-2008 English PDF (GB/T2059-2008)

GB/T 2059-2008 English PDF (GB/T2059-2008)

Regular price

$105.00

Regular price

Sale price

$105.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 2059-2008: Strip of copper and copper alloy

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.

Newer version: (Replacing this standard) GB/T 2059-2017

Get Quotation: Click GB/T 2059-2008 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 2059-2017

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 2059-2008

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.150.30

H 62

Replacing GB/T 2059-2000, GB/T 2067-1980, GB/T 2069-1980,

GB/T 11089-1989, GB/T 15714-1995

Strip of Copper and Copper Alloy

ISSUED ON: JUNE 17, 2008

IMPLEMENTED ON: DECEMBER 1, 2008

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration of the People’s Republic of

China.

Have been Replaced

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Requirements ... 6

4 Test Methods ... 14

5 Inspection Rules ... 15

6 Marking, Packaging, Transportation, Storage and Quality Certificate ... 16

7 Order Sheet (or contract) Contents ... 16

Foreword

This Standard adopts the Japanese industrial standards JIS H3100-2006 Copper and

Copper Alloy Sheets, Plates and Strips and JIS H3110-2006 Phosphor Bronze and

Nickel Silver Sheets, Plates and Strips by modification; adopts the EU standard BS EN

1652:1998 Copper and Copper Alloys - Plate, Sheet, Strip and Circles for General

Purposes by reference.

This Standard serves as a replacement of GB/T 2059-2000 Strips of Copper and

Copper Alloys, GB/T 2067-1980 Tin-zinc-lead-bronze Strips, GB/T 2069-1980

Aluminum-copper-nickel Alloy Strips, GB/T 11089-1989 Leaded Brass Strips for

Special Purpose and GB/T 15714-1995 Brass (H65) Strip for Welded Tube.

In comparison with GB/T 2059-2000, GB/T 2067-1980, GB/T 2069-1980, GB/T 11089-

1989 and GB/T 15714-1995, the main changes are as follows:

---Four designations (H63, H85, QSn8-0.3 and BZn18-17) are added. In addition,

Designation C2300 in JIS H3100-2006 and Designation CuZn15 in the EN

standard are used to specify the mechanical properties of Designation H85;

Designation C5212 in JIS H3110-2006 is used to specify the mechanical

properties of Designation QSn8-0.3; Designation C7521 in JIS H3110-2006 is

used to specify the chemical composition and mechanical properties of

Designation BZn18-17;

---For pure copper, the extra-hard (T) state is added; the mechanical properties of

the hard (Y) state are accordingly modified;

---The elastic-hard (TY) state is added to H70, H65, H65 and QSn6.5-0.1; JIS

H3100-2006 and JIS H3110-2006 are used to modify the tensile strength values;

---The lower limit of the available thickness of the strip is modified from “0.05 mm”

to “greater than 0.15 mm”; for pure copper and ordinary brass, the upper limit

of the width of strip with a thickness of 0.5 mm ~ 3.0 mm is expanded from

“1,000 mm” to “1,200 mm”;

---The overall dimensions and tolerances shall comply with the stipulations of GB/T

17793;

---The hardness test is modified from “an optional reference item” into “a routine

inspection item”; it is also stipulated that “choose either tensile test or hardness

test, and when there are no special instructions, provide tensile test”;

---The measurable thickness of the tensile test is modified from not less than “0.3

mm” into not less than “0.2 mm and 0.15 mm”; the thickness requirements for

the hardness test are deleted (that is, all specifications may be tested);

Strip of Copper and Copper Alloy

1 Scope

This Standard specifies the requirements, test methods, inspection rules, marking,

packaging, transportation, storage and order sheet (or contract) content of wrought

copper and copper alloy strip.

This Standard is applicable to wrought copper and copper alloy strip for general

purposes.

2 Normative References

Through the reference in this Standard, the clauses of the following documents

become clauses of this Standard. In terms of references with a specified date, all the

subsequent modification sheets (excluding the corrected content) or revised versions

are not applicable to this Standard. However, the various parties that reach an

agreement in accordance with this Standard are encouraged to explore the possibility

of adopting the latest version of these documents. In terms of references without a

specified date, the latest version is applicable to this Standard.

GB/T 228-2002 Metallic Materials - Tensile Testing at Ambient Temperature

GB/T 230.1 Metallic Materials - Rockwell Hardness Test - Part 1: Test Method (scales

A, B, C, D, E, F, G, H, K, N, T)

GB/T 232 Metallic Materials - Bend Test

GB/T 351 Metallic Materials - Resistivity Measurement Method

GB/T 4340.1 Metallic Materials - Vickers Hardness Test - Part 1: Test Method

GB/T 5121 (all parts) Methods for Chemical Analysis of Copper and Copper Alloys

GB/T 5231 Wrought Copper and Copper Alloys Chemical Composition Limits and

Forms of Wrought Products

GB/T 6147 Test Method for Thermoelectric Power of Precision Resistance Alloys

GB/T 6148 Test Method for Temperature-resistance Coefficient of Precision

Resistance Alloys

GB/T 8888 Wrought Heavy Non-ferrous Metal Products - Packing, Marking,

Transporting and Storing

3.1.2 Example of marking

Product marking shall be expressed in the sequence of product name, designation,

state, specification and serial No. of Standard. An example of marking is as follows:

The strip made of H62, in semi-hard (Y2) state, with a thickness of 0.8 mm and a width

of 200 mm shall be marked as:

Strip H62Y2 0.8200 GB/T 2059-2008

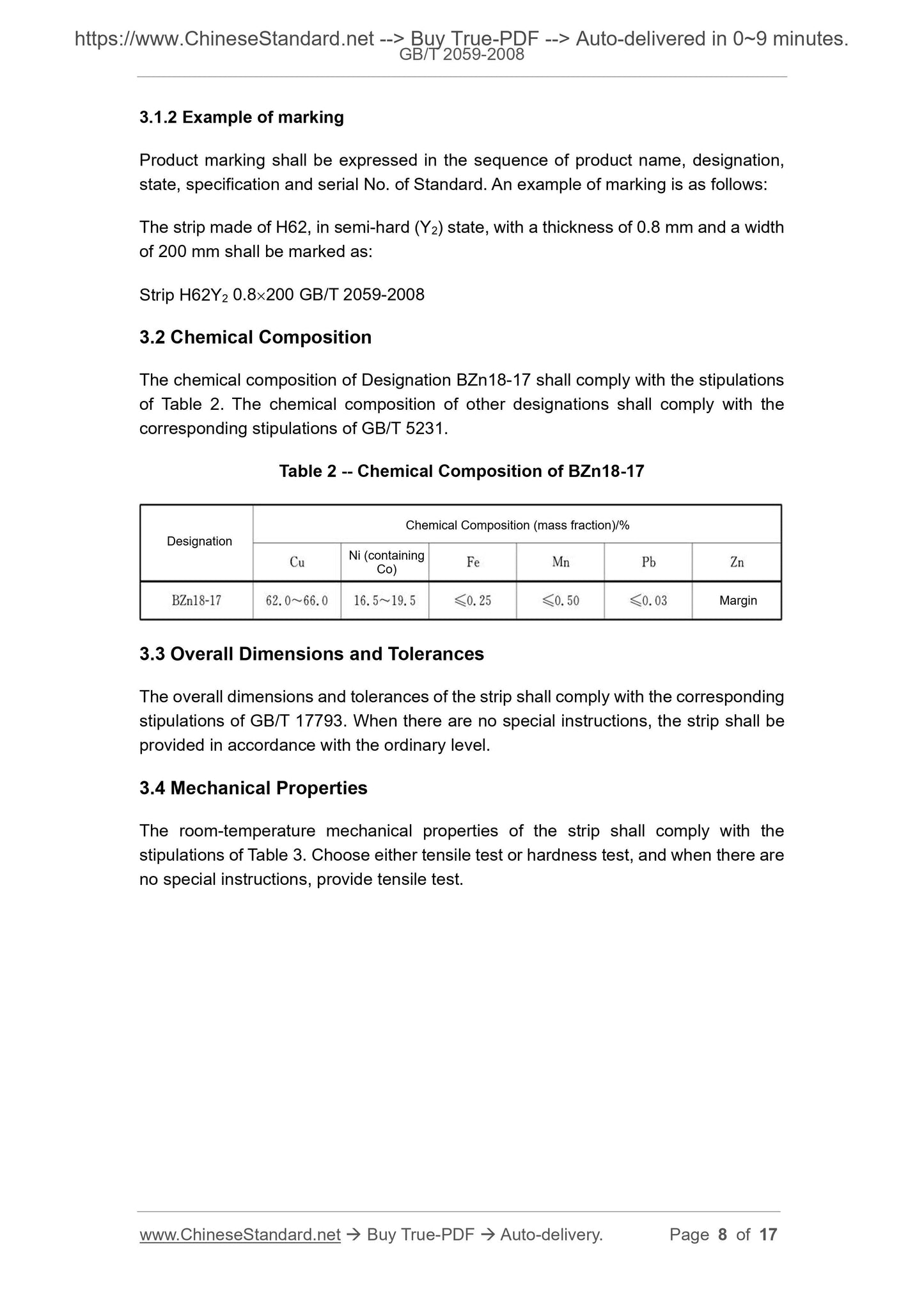

3.2 Chemical Composition

The chemical composition of Designation BZn18-17 shall comply with the stipulations

of Table 2. The chemical composition of other designations shall comply with the

corresponding stipulations of GB/T 5231.

Table 2 -- Chemical Composition of BZn18-17

3.3 Overall Dimensions and Tolerances

The overall dimensions and tolerances of the strip shall comply with the corresponding

stipulations of GB/T 17793. When there are no special instructions, the strip shall be

provided in accordance with the ordinary level.

3.4 Mechanical Properties

The room-temperature mechanical properties of the strip shall comply with the

stipulations of Table 3. Choose either tensile test or hardness test, and when there are

no special instructions, provide tensile test.

Chemical Composition (mass fraction)/%

Designation

Margin

Ni (containing

Co)

the thickness of the strip to exceed the tolerances.

4 Test Methods

4.1 Arbitration Analysis Method of Chemical Composition

The arbitration analysis method of the chemical composition of the strip shall comply

with the stipulations of GB/T 5121.

4.2 Measurement Method of Overall Dimensions

The overall dimensions of the strip shall be measured with measuring tools of

corresponding precisions. When the strip width is > 100 mm, measure at a distance of

≥ 5 mm from the edge; when the strip width is ≤ 100 mm, measure at a distance of ≥ 3

mm from the edge.

4.3 Inspection Method of Mechanical Properties

The tensile test of the strip shall be conducted in accordance with the stipulations of

GB/T 228. The selection of specimens shall comply with the stipulations of P02 in Table

A1 of Appendix A of GB/T 228-2002. The test of Vickers hardness shall be conducted

in accordance with the stipulations of GB/T 4340.1. The test of Rockwell hardness shall

be conducted in accordance with the stipulations of GB/T 230.1.

4.4 Method of Bend Test

The bend test of the strip shall be conducted in accordance with the stipulations of

GB/T 232.

4.5 Inspection Method of Electrical Properties

4.5.1 The resistivity test of the strip shall be conducted in accordance with the

stipulations of GB/T 351.

4.5.2 The test of the temperature-resistance coefficient of the strip shall be conducted

in accordance with the stipulations of GB/T 6148.

4.5.3 The thermoelectric power test of the strip shall be conducted in accordance with

the stipulations of GB/T 6147.

4.6 Inspection Method of Grain Size

The grain size inspection of the strip shall be conducted in accordance with the

stipulations of YS/T 347.

4.7 Inspection Method of Surface Quality

The surface quality of the strip shall be visually inspected.

5.5 Determination of Inspection Result

5.5.1 When the chemical composition is disqualified, the batch of strip shall be

determined as disqualified.

5.5.2 When the overall dimensions and tolerances, and the surface quality are

disqualified, the coil of strip shall be determined as disqualified.

5.5.3 When there are disqualified specimens in the test results of mechanical

properties, bend test, electrical properties and grain size, from the batch of strip

(including the coil of strip that failed the previous inspection), take double number of

specimens for a repeated test. If the results of the repeated test are all qualified, then,

the whole batch of products shall be determined as qualified. If there are still

disqualified specimens in the results of the repeated test, then, the batch of strip shall

be determined as disqualified, or the supply-side shall inspect coil by coil and deliver

the qualified ones.

6 Marking, Packaging, Transportation, Storage and

Quality Certificate

The marking, packaging, transportation, storage and quality certificate of the products

shall comply with the stipulations of GB/T 8888.

7 Order Sheet (or contract) Contents

The order sheet (or contract) ordering the products listed in this Standard shall include

the following contents:

a) Product name;

b) Designation;

c) State of delivery;

d) Dimensions and specifications;

GB/T 2059-2008

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.150.30

H 62

Replacing GB/T 2059-2000, GB/T 2067-1980, GB/T 2069-1980,

GB/T 11089-1989, GB/T 15714-1995

Strip of Copper and Copper Alloy

ISSUED ON: JUNE 17, 2008

IMPLEMENTED ON: DECEMBER 1, 2008

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration of the People’s Republic of

China.

Have been Replaced

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Requirements ... 6

4 Test Methods ... 14

5 Inspection Rules ... 15

6 Marking, Packaging, Transportation, Storage and Quality Certificate ... 16

7 Order Sheet (or contract) Contents ... 16

Foreword

This Standard adopts the Japanese industrial standards JIS H3100-2006 Copper and

Copper Alloy Sheets, Plates and Strips and JIS H3110-2006 Phosphor Bronze and

Nickel Silver Sheets, Plates and Strips by modification; adopts the EU standard BS EN

1652:1998 Copper and Copper Alloys - Plate, Sheet, Strip and Circles for General

Purposes by reference.

This Standard serves as a replacement of GB/T 2059-2000 Strips of Copper and

Copper Alloys, GB/T 2067-1980 Tin-zinc-lead-bronze Strips, GB/T 2069-1980

Aluminum-copper-nickel Alloy Strips, GB/T 11089-1989 Leaded Brass Strips for

Special Purpose and GB/T 15714-1995 Brass (H65) Strip for Welded Tube.

In comparison with GB/T 2059-2000, GB/T 2067-1980, GB/T 2069-1980, GB/T 11089-

1989 and GB/T 15714-1995, the main changes are as follows:

---Four designations (H63, H85, QSn8-0.3 and BZn18-17) are added. In addition,

Designation C2300 in JIS H3100-2006 and Designation CuZn15 in the EN

standard are used to specify the mechanical properties of Designation H85;

Designation C5212 in JIS H3110-2006 is used to specify the mechanical

properties of Designation QSn8-0.3; Designation C7521 in JIS H3110-2006 is

used to specify the chemical composition and mechanical properties of

Designation BZn18-17;

---For pure copper, the extra-hard (T) state is added; the mechanical properties of

the hard (Y) state are accordingly modified;

---The elastic-hard (TY) state is added to H70, H65, H65 and QSn6.5-0.1; JIS

H3100-2006 and JIS H3110-2006 are used to modify the tensile strength values;

---The lower limit of the available thickness of the strip is modified from “0.05 mm”

to “greater than 0.15 mm”; for pure copper and ordinary brass, the upper limit

of the width of strip with a thickness of 0.5 mm ~ 3.0 mm is expanded from

“1,000 mm” to “1,200 mm”;

---The overall dimensions and tolerances shall comply with the stipulations of GB/T

17793;

---The hardness test is modified from “an optional reference item” into “a routine

inspection item”; it is also stipulated that “choose either tensile test or hardness

test, and when there are no special instructions, provide tensile test”;

---The measurable thickness of the tensile test is modified from not less than “0.3

mm” into not less than “0.2 mm and 0.15 mm”; the thickness requirements for

the hardness test are deleted (that is, all specifications may be tested);

Strip of Copper and Copper Alloy

1 Scope

This Standard specifies the requirements, test methods, inspection rules, marking,

packaging, transportation, storage and order sheet (or contract) content of wrought

copper and copper alloy strip.

This Standard is applicable to wrought copper and copper alloy strip for general

purposes.

2 Normative References

Through the reference in this Standard, the clauses of the following documents

become clauses of this Standard. In terms of references with a specified date, all the

subsequent modification sheets (excluding the corrected content) or revised versions

are not applicable to this Standard. However, the various parties that reach an

agreement in accordance with this Standard are encouraged to explore the possibility

of adopting the latest version of these documents. In terms of references without a

specified date, the latest version is applicable to this Standard.

GB/T 228-2002 Metallic Materials - Tensile Testing at Ambient Temperature

GB/T 230.1 Metallic Materials - Rockwell Hardness Test - Part 1: Test Method (scales

A, B, C, D, E, F, G, H, K, N, T)

GB/T 232 Metallic Materials - Bend Test

GB/T 351 Metallic Materials - Resistivity Measurement Method

GB/T 4340.1 Metallic Materials - Vickers Hardness Test - Part 1: Test Method

GB/T 5121 (all parts) Methods for Chemical Analysis of Copper and Copper Alloys

GB/T 5231 Wrought Copper and Copper Alloys Chemical Composition Limits and

Forms of Wrought Products

GB/...

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.

Newer version: (Replacing this standard) GB/T 2059-2017

Get Quotation: Click GB/T 2059-2008 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 2059-2017

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 2059-2008

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.150.30

H 62

Replacing GB/T 2059-2000, GB/T 2067-1980, GB/T 2069-1980,

GB/T 11089-1989, GB/T 15714-1995

Strip of Copper and Copper Alloy

ISSUED ON: JUNE 17, 2008

IMPLEMENTED ON: DECEMBER 1, 2008

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration of the People’s Republic of

China.

Have been Replaced

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Requirements ... 6

4 Test Methods ... 14

5 Inspection Rules ... 15

6 Marking, Packaging, Transportation, Storage and Quality Certificate ... 16

7 Order Sheet (or contract) Contents ... 16

Foreword

This Standard adopts the Japanese industrial standards JIS H3100-2006 Copper and

Copper Alloy Sheets, Plates and Strips and JIS H3110-2006 Phosphor Bronze and

Nickel Silver Sheets, Plates and Strips by modification; adopts the EU standard BS EN

1652:1998 Copper and Copper Alloys - Plate, Sheet, Strip and Circles for General

Purposes by reference.

This Standard serves as a replacement of GB/T 2059-2000 Strips of Copper and

Copper Alloys, GB/T 2067-1980 Tin-zinc-lead-bronze Strips, GB/T 2069-1980

Aluminum-copper-nickel Alloy Strips, GB/T 11089-1989 Leaded Brass Strips for

Special Purpose and GB/T 15714-1995 Brass (H65) Strip for Welded Tube.

In comparison with GB/T 2059-2000, GB/T 2067-1980, GB/T 2069-1980, GB/T 11089-

1989 and GB/T 15714-1995, the main changes are as follows:

---Four designations (H63, H85, QSn8-0.3 and BZn18-17) are added. In addition,

Designation C2300 in JIS H3100-2006 and Designation CuZn15 in the EN

standard are used to specify the mechanical properties of Designation H85;

Designation C5212 in JIS H3110-2006 is used to specify the mechanical

properties of Designation QSn8-0.3; Designation C7521 in JIS H3110-2006 is

used to specify the chemical composition and mechanical properties of

Designation BZn18-17;

---For pure copper, the extra-hard (T) state is added; the mechanical properties of

the hard (Y) state are accordingly modified;

---The elastic-hard (TY) state is added to H70, H65, H65 and QSn6.5-0.1; JIS

H3100-2006 and JIS H3110-2006 are used to modify the tensile strength values;

---The lower limit of the available thickness of the strip is modified from “0.05 mm”

to “greater than 0.15 mm”; for pure copper and ordinary brass, the upper limit

of the width of strip with a thickness of 0.5 mm ~ 3.0 mm is expanded from

“1,000 mm” to “1,200 mm”;

---The overall dimensions and tolerances shall comply with the stipulations of GB/T

17793;

---The hardness test is modified from “an optional reference item” into “a routine

inspection item”; it is also stipulated that “choose either tensile test or hardness

test, and when there are no special instructions, provide tensile test”;

---The measurable thickness of the tensile test is modified from not less than “0.3

mm” into not less than “0.2 mm and 0.15 mm”; the thickness requirements for

the hardness test are deleted (that is, all specifications may be tested);

Strip of Copper and Copper Alloy

1 Scope

This Standard specifies the requirements, test methods, inspection rules, marking,

packaging, transportation, storage and order sheet (or contract) content of wrought

copper and copper alloy strip.

This Standard is applicable to wrought copper and copper alloy strip for general

purposes.

2 Normative References

Through the reference in this Standard, the clauses of the following documents

become clauses of this Standard. In terms of references with a specified date, all the

subsequent modification sheets (excluding the corrected content) or revised versions

are not applicable to this Standard. However, the various parties that reach an

agreement in accordance with this Standard are encouraged to explore the possibility

of adopting the latest version of these documents. In terms of references without a

specified date, the latest version is applicable to this Standard.

GB/T 228-2002 Metallic Materials - Tensile Testing at Ambient Temperature

GB/T 230.1 Metallic Materials - Rockwell Hardness Test - Part 1: Test Method (scales

A, B, C, D, E, F, G, H, K, N, T)

GB/T 232 Metallic Materials - Bend Test

GB/T 351 Metallic Materials - Resistivity Measurement Method

GB/T 4340.1 Metallic Materials - Vickers Hardness Test - Part 1: Test Method

GB/T 5121 (all parts) Methods for Chemical Analysis of Copper and Copper Alloys

GB/T 5231 Wrought Copper and Copper Alloys Chemical Composition Limits and

Forms of Wrought Products

GB/T 6147 Test Method for Thermoelectric Power of Precision Resistance Alloys

GB/T 6148 Test Method for Temperature-resistance Coefficient of Precision

Resistance Alloys

GB/T 8888 Wrought Heavy Non-ferrous Metal Products - Packing, Marking,

Transporting and Storing

3.1.2 Example of marking

Product marking shall be expressed in the sequence of product name, designation,

state, specification and serial No. of Standard. An example of marking is as follows:

The strip made of H62, in semi-hard (Y2) state, with a thickness of 0.8 mm and a width

of 200 mm shall be marked as:

Strip H62Y2 0.8200 GB/T 2059-2008

3.2 Chemical Composition

The chemical composition of Designation BZn18-17 shall comply with the stipulations

of Table 2. The chemical composition of other designations shall comply with the

corresponding stipulations of GB/T 5231.

Table 2 -- Chemical Composition of BZn18-17

3.3 Overall Dimensions and Tolerances

The overall dimensions and tolerances of the strip shall comply with the corresponding

stipulations of GB/T 17793. When there are no special instructions, the strip shall be

provided in accordance with the ordinary level.

3.4 Mechanical Properties

The room-temperature mechanical properties of the strip shall comply with the

stipulations of Table 3. Choose either tensile test or hardness test, and when there are

no special instructions, provide tensile test.

Chemical Composition (mass fraction)/%

Designation

Margin

Ni (containing

Co)

the thickness of the strip to exceed the tolerances.

4 Test Methods

4.1 Arbitration Analysis Method of Chemical Composition

The arbitration analysis method of the chemical composition of the strip shall comply

with the stipulations of GB/T 5121.

4.2 Measurement Method of Overall Dimensions

The overall dimensions of the strip shall be measured with measuring tools of

corresponding precisions. When the strip width is > 100 mm, measure at a distance of

≥ 5 mm from the edge; when the strip width is ≤ 100 mm, measure at a distance of ≥ 3

mm from the edge.

4.3 Inspection Method of Mechanical Properties

The tensile test of the strip shall be conducted in accordance with the stipulations of

GB/T 228. The selection of specimens shall comply with the stipulations of P02 in Table

A1 of Appendix A of GB/T 228-2002. The test of Vickers hardness shall be conducted

in accordance with the stipulations of GB/T 4340.1. The test of Rockwell hardness shall

be conducted in accordance with the stipulations of GB/T 230.1.

4.4 Method of Bend Test

The bend test of the strip shall be conducted in accordance with the stipulations of

GB/T 232.

4.5 Inspection Method of Electrical Properties

4.5.1 The resistivity test of the strip shall be conducted in accordance with the

stipulations of GB/T 351.

4.5.2 The test of the temperature-resistance coefficient of the strip shall be conducted

in accordance with the stipulations of GB/T 6148.

4.5.3 The thermoelectric power test of the strip shall be conducted in accordance with

the stipulations of GB/T 6147.

4.6 Inspection Method of Grain Size

The grain size inspection of the strip shall be conducted in accordance with the

stipulations of YS/T 347.

4.7 Inspection Method of Surface Quality

The surface quality of the strip shall be visually inspected.

5.5 Determination of Inspection Result

5.5.1 When the chemical composition is disqualified, the batch of strip shall be

determined as disqualified.

5.5.2 When the overall dimensions and tolerances, and the surface quality are

disqualified, the coil of strip shall be determined as disqualified.

5.5.3 When there are disqualified specimens in the test results of mechanical

properties, bend test, electrical properties and grain size, from the batch of strip

(including the coil of strip that failed the previous inspection), take double number of

specimens for a repeated test. If the results of the repeated test are all qualified, then,

the whole batch of products shall be determined as qualified. If there are still

disqualified specimens in the results of the repeated test, then, the batch of strip shall

be determined as disqualified, or the supply-side shall inspect coil by coil and deliver

the qualified ones.

6 Marking, Packaging, Transportation, Storage and

Quality Certificate

The marking, packaging, transportation, storage and quality certificate of the products

shall comply with the stipulations of GB/T 8888.

7 Order Sheet (or contract) Contents

The order sheet (or contract) ordering the products listed in this Standard shall include

the following contents:

a) Product name;

b) Designation;

c) State of delivery;

d) Dimensions and specifications;

GB/T 2059-2008

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.150.30

H 62

Replacing GB/T 2059-2000, GB/T 2067-1980, GB/T 2069-1980,

GB/T 11089-1989, GB/T 15714-1995

Strip of Copper and Copper Alloy

ISSUED ON: JUNE 17, 2008

IMPLEMENTED ON: DECEMBER 1, 2008

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration of the People’s Republic of

China.

Have been Replaced

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Requirements ... 6

4 Test Methods ... 14

5 Inspection Rules ... 15

6 Marking, Packaging, Transportation, Storage and Quality Certificate ... 16

7 Order Sheet (or contract) Contents ... 16

Foreword

This Standard adopts the Japanese industrial standards JIS H3100-2006 Copper and

Copper Alloy Sheets, Plates and Strips and JIS H3110-2006 Phosphor Bronze and

Nickel Silver Sheets, Plates and Strips by modification; adopts the EU standard BS EN

1652:1998 Copper and Copper Alloys - Plate, Sheet, Strip and Circles for General

Purposes by reference.

This Standard serves as a replacement of GB/T 2059-2000 Strips of Copper and

Copper Alloys, GB/T 2067-1980 Tin-zinc-lead-bronze Strips, GB/T 2069-1980

Aluminum-copper-nickel Alloy Strips, GB/T 11089-1989 Leaded Brass Strips for

Special Purpose and GB/T 15714-1995 Brass (H65) Strip for Welded Tube.

In comparison with GB/T 2059-2000, GB/T 2067-1980, GB/T 2069-1980, GB/T 11089-

1989 and GB/T 15714-1995, the main changes are as follows:

---Four designations (H63, H85, QSn8-0.3 and BZn18-17) are added. In addition,

Designation C2300 in JIS H3100-2006 and Designation CuZn15 in the EN

standard are used to specify the mechanical properties of Designation H85;

Designation C5212 in JIS H3110-2006 is used to specify the mechanical

properties of Designation QSn8-0.3; Designation C7521 in JIS H3110-2006 is

used to specify the chemical composition and mechanical properties of

Designation BZn18-17;

---For pure copper, the extra-hard (T) state is added; the mechanical properties of

the hard (Y) state are accordingly modified;

---The elastic-hard (TY) state is added to H70, H65, H65 and QSn6.5-0.1; JIS

H3100-2006 and JIS H3110-2006 are used to modify the tensile strength values;

---The lower limit of the available thickness of the strip is modified from “0.05 mm”

to “greater than 0.15 mm”; for pure copper and ordinary brass, the upper limit

of the width of strip with a thickness of 0.5 mm ~ 3.0 mm is expanded from

“1,000 mm” to “1,200 mm”;

---The overall dimensions and tolerances shall comply with the stipulations of GB/T

17793;

---The hardness test is modified from “an optional reference item” into “a routine

inspection item”; it is also stipulated that “choose either tensile test or hardness

test, and when there are no special instructions, provide tensile test”;

---The measurable thickness of the tensile test is modified from not less than “0.3

mm” into not less than “0.2 mm and 0.15 mm”; the thickness requirements for

the hardness test are deleted (that is, all specifications may be tested);

Strip of Copper and Copper Alloy

1 Scope

This Standard specifies the requirements, test methods, inspection rules, marking,

packaging, transportation, storage and order sheet (or contract) content of wrought

copper and copper alloy strip.

This Standard is applicable to wrought copper and copper alloy strip for general

purposes.

2 Normative References

Through the reference in this Standard, the clauses of the following documents

become clauses of this Standard. In terms of references with a specified date, all the

subsequent modification sheets (excluding the corrected content) or revised versions

are not applicable to this Standard. However, the various parties that reach an

agreement in accordance with this Standard are encouraged to explore the possibility

of adopting the latest version of these documents. In terms of references without a

specified date, the latest version is applicable to this Standard.

GB/T 228-2002 Metallic Materials - Tensile Testing at Ambient Temperature

GB/T 230.1 Metallic Materials - Rockwell Hardness Test - Part 1: Test Method (scales

A, B, C, D, E, F, G, H, K, N, T)

GB/T 232 Metallic Materials - Bend Test

GB/T 351 Metallic Materials - Resistivity Measurement Method

GB/T 4340.1 Metallic Materials - Vickers Hardness Test - Part 1: Test Method

GB/T 5121 (all parts) Methods for Chemical Analysis of Copper and Copper Alloys

GB/T 5231 Wrought Copper and Copper Alloys Chemical Composition Limits and

Forms of Wrought Products

GB/...

Share