1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB 50516-2021 English PDF

GB 50516-2021 English PDF

Regular price

$395.00

Regular price

Sale price

$395.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB 50516-2021: [2021 Edition of GB 50516-2010] Technical code for hydrogen fuelling station

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB 50516-2021 (Self-service in 1-minute)

Newer / historical versions: GB 50516-2021

Preview True-PDF

Scope

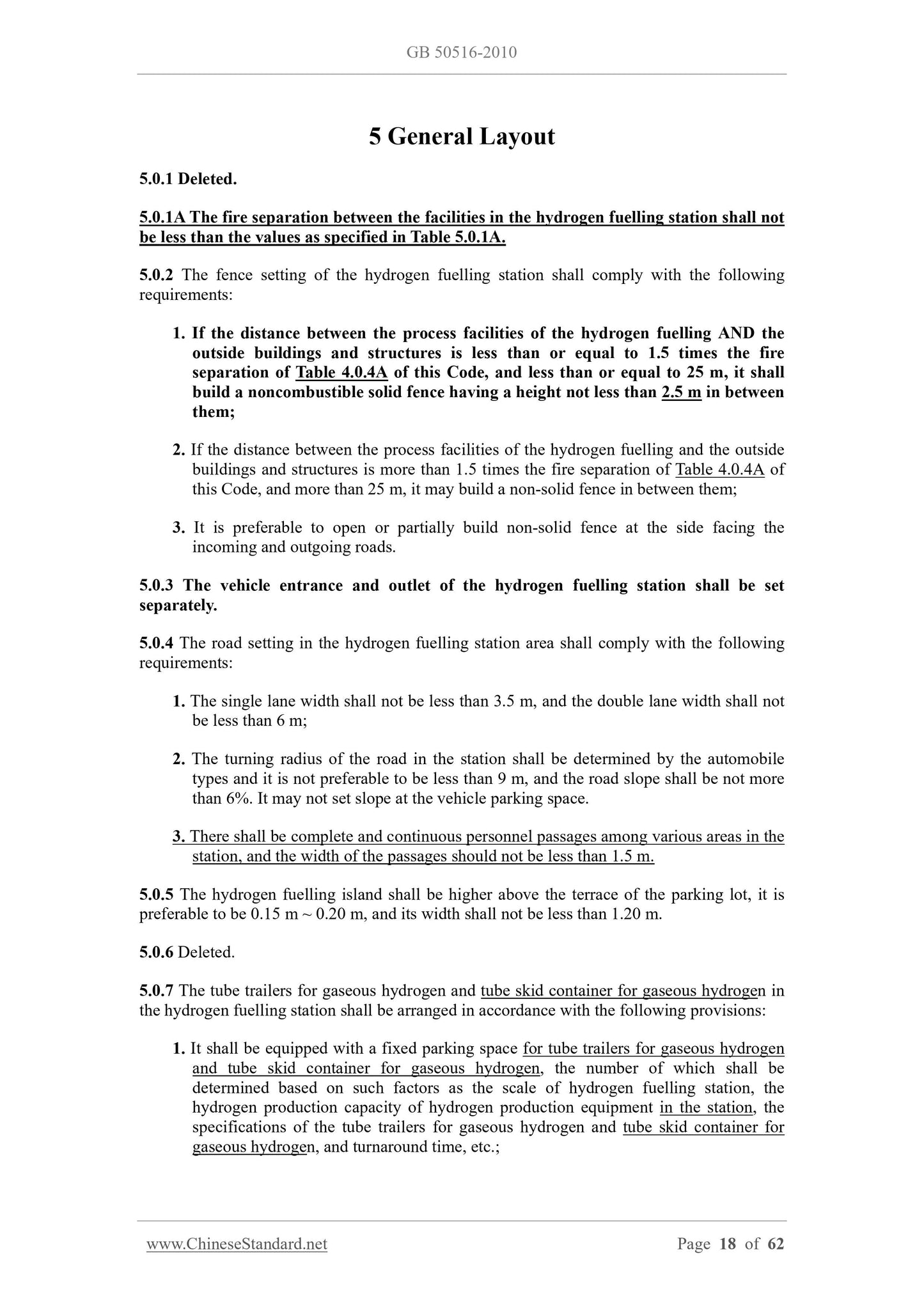

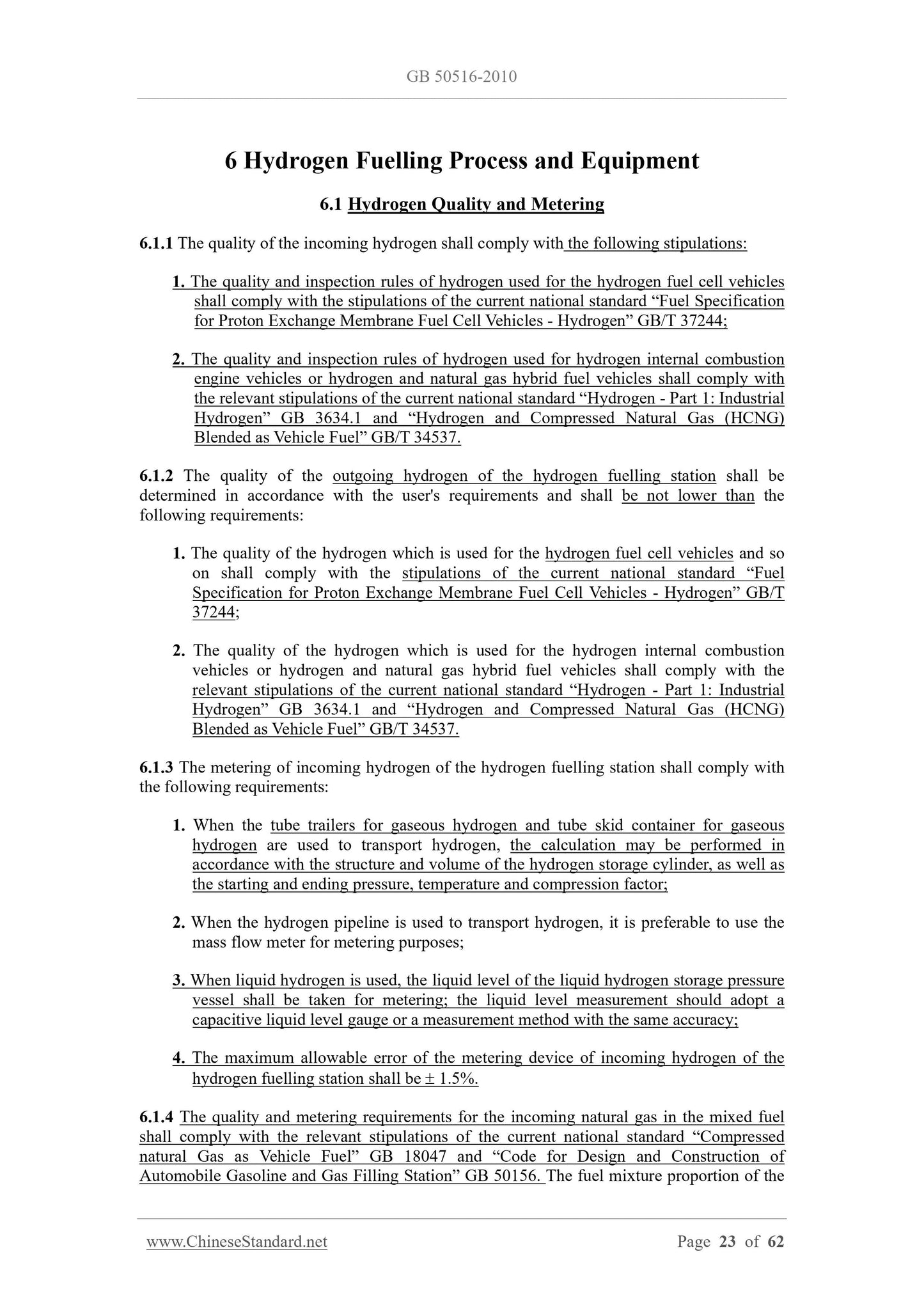

1.0.1 This code is established in order to implement the relevant national policies in thedesign, construction and operation process of the hydrogen fuelling station, unify the

technical requirements, and realize safety and reliability, advanced technology, energy saving

and emission reduction, and economic rationality.

1.0.2 This code applies to the design, construction, and building of newly built, rebuilt and

extended hydrogen fuelling station projects.

1.0.3 The design, construction and building of the hydrogen fuelling station shall, in addition

to complying with this code, comply with the requirements of the relevant national standards.

Share